Porous perovskite film, carbon slurry and carbon electrode based solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of large amount of perovskite materials, rough and uneven surface, affecting battery performance, etc., and achieve easy large-scale application, high conversion efficiency, and improved utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Next, a method for preparing the perovskite thin film will be described. The perovskite film of the present invention can be prepared by a solution method.

[0057]Preparation of perovskite precursor solution: Dissolve the halide of B and the monovalent cation salt of X (such as the organic amine salt of X) in a solvent with oxygen-containing groups at a certain ratio to form a perovskite precursor solution. The oxygen-containing group solvent can be a single solvent or a mixed solvent such as dimethylsulfoxide (DMSO), dimethylformamide (DMF), γ-butyrolactone (GBL), N-methyl-2-pyrrolidone, etc. solvent. By selecting different solvents, the porous morphology of the obtained perovskite film can be tuned. The molar ratio of the halide of B to the monovalent cation salt of X may be 1:10˜10:1, for example, 1:1. The mass ratio of the halide of B to the solvent may be 1:10˜10:1. In one example, the halide of B, the monovalent cation salt of X, and DMSO are in a molar ratio...

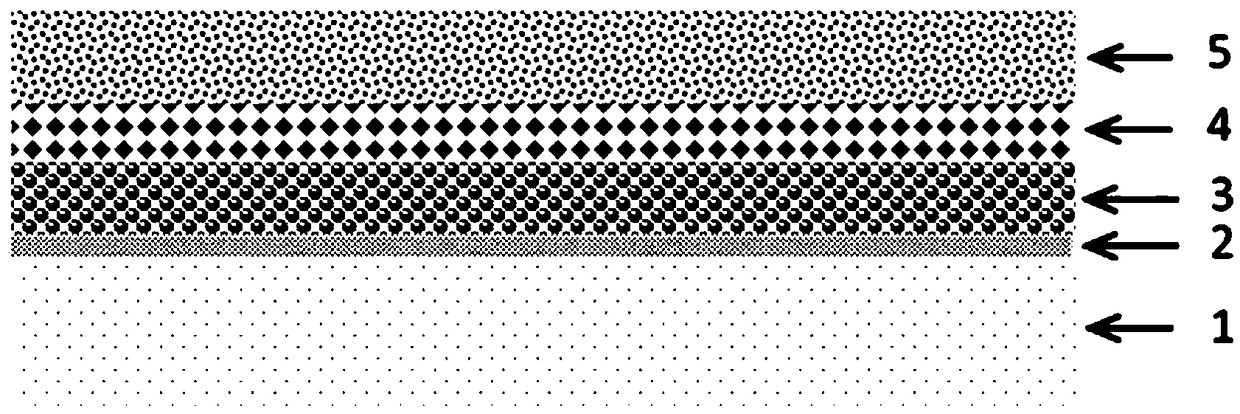

Embodiment 1

[0087] (1) Cleaning of the conductive substrate. Use acetone, alkaline detergent, deionized water, and acetone to ultrasonically clean the FTO glass for 10 minutes, and finally dry it with compressed air, and finally place it in a UV ozone machine for 15 minutes to remove residual organic impurities and enhance the wetting of the substrate to the solution sex;

[0088] (2) Preparation of hole blocking layer. The precursor solution solvent is ethanol, which includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), hydrochloric acid (0.09mol / L), water (1.8mol / L). Take the precursor solution, drop it on the FTO in step (1), make the solution cover the entire FTO surface, spin coating at a speed of 3000rpm for 20s, and then dry at 120°C for 30min;

[0089] (3) Preparation of mesoporous electron transport layer. With 20wt% nano-TiO 2 The slurry is used as the material, and the mesoporous TiO is coated on the hole blocking layer by the scr...

Embodiment 2

[0094] (1) Cleaning of the conductive substrate. With embodiment 1;

[0095] (2) Preparation of hole blocking layer. With embodiment 1;

[0096] (3) Preparation of mesoporous electron transport layer. With embodiment 1;

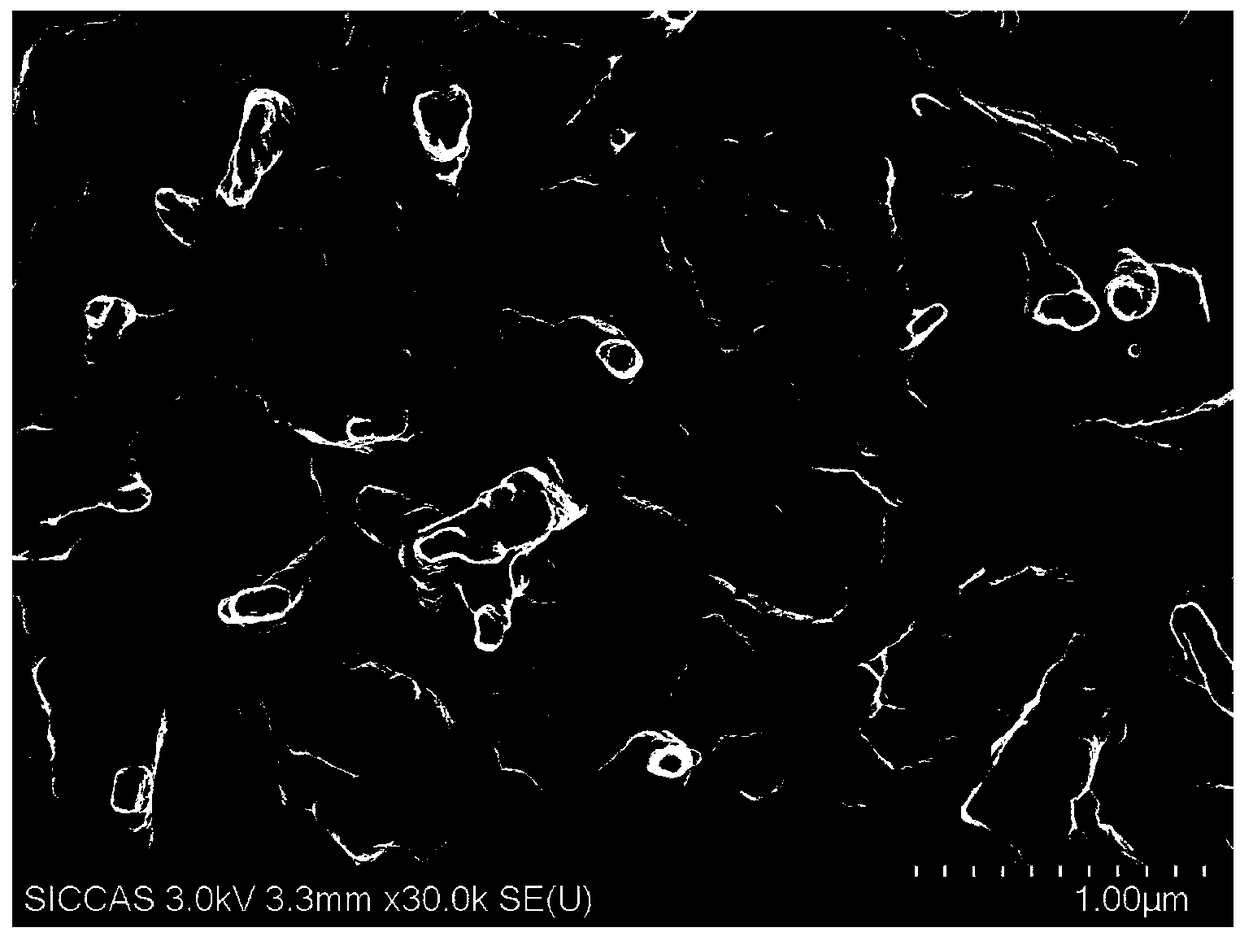

[0097] (4) Preparation of porous perovskite layer. 1.383g of PbI 2 , 0.477g of MAI and 212.7μL of DMSO were dissolved in 1.9047mL of DMF at a molar ratio of 1:1:1 and stirred thoroughly, and perovskite was added dropwise on the substrate of FTO / hole blocking layer / mesoporous layer. The precursor solution was spin-coated at a speed of 5000rpm for 20s, and then 0.5mL of n-hexane was added dropwise at a rate of 0.25mL / s at 6 seconds to obtain a perovskite precursor film. Then annealed on a hot plate at 100°C for 10 minutes to obtain a dense perovskite film with a porous upper and lower layers, such as Figure 5 shown;

[0098] (5) Preparation of carbon counter electrode layer. With embodiment 1;

[0099] (6) Leading out the transparent conductive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com