Preparation method of nanofiltration membrane

A technology of nanofiltration membrane and support membrane, which is applied in the field of preparation of acid chloride modified nano-TiO2 particle hybrid PVA-polypiperazine amide nanofiltration membrane, which can solve the problems affecting the dispersion effect of nanoparticles and the performance of nanofiltration membrane. To achieve the effect of easy operation, improved flux, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Configuration mass concentration is 0.2% trimesoyl chloride (TMC) organic phase solution, wherein solvent is IsoparG; Configuration mass concentration is 0.2% piperazine aqueous solution, then adding mass concentration is 0.05% medium molecular weight polyvinyl alcohol (PVA) , soak the polysulfone support membrane in piperazine aqueous solution for 120 seconds, and then roll the polysulfone support membrane with a rubber roller to remove excess solution; after the solution is dry, contact with the organic phase solution for 20 seconds; put the membrane Into a vacuum oven at 80° C. for 12 minutes, and dried to obtain a hybrid nanofiltration composite membrane. Use 2000ppm of sodium sulfate aqueous solution, sodium chloride aqueous solution, PEG-200 aqueous solution and PEG-400 aqueous solution to test the initial performance of the membrane under the pressure of 1MPa, and the membrane is resistant to Na 2 SO 4 The desalination rates of NaCl and NaCl were 98.4% and 53.2%...

Embodiment 2

[0020] Prepare an organic phase solution of trimesoyl chloride (TMC) with a mass concentration of 0.2%, in which the solvent is IsoparG, then add a certain amount of TMC modified nano-titanium dioxide particles, ultrasonically disperse for 1 hour, and form a uniform suspension with a mass concentration of 0.005% solution; the configuration mass concentration is 0.2% piperazine aqueous solution, then add the medium molecular weight polyvinyl alcohol (PVA) that mass concentration is 0.05%, put the polysulfone support membrane into the piperazine aqueous solution and soak for 120 seconds, wherein then use rubber roller Roll the polysulfone support membrane to remove excess solution; after the solution is dry, contact with the organic phase solution just after ultrasonic dispersion for 20 seconds; put the membrane in a vacuum oven at 80°C for 12 minutes, and dry to obtain hybrid nano Filter the composite membrane and test it, the membrane is against Na 2 SO 4 The desalination rat...

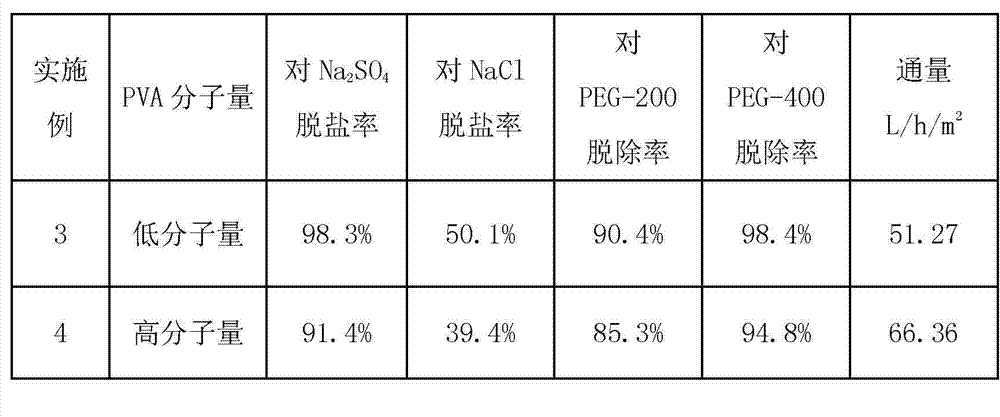

Embodiment 3-4

[0022] Change the molecular weight of polyvinyl alcohol (PVA) in the aqueous phase solution, other steps are the same operating method as embodiment 1, prepare composite film and test, obtain the result as following table:

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com