MXene-based bismuth-based photocatalytic composite membrane and preparation method thereof

A photocatalytic and composite membrane technology, which is applied in catalyst activation/preparation, chemical instruments and methods, special compound water treatment, etc. low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a bismuth-based photocatalytic composite film based on MXene, comprising the following steps:

[0031] Step 1: First configure the MXene aqueous dispersion with a concentration of 0.05-5 mg / mL, and then add a reducing agent, which is any one of oxalic acid, urea and sodium ascorbate;

[0032] The second step: add bismuth source and sulfur source to the MXene aqueous dispersion, stir evenly to form a mixed aqueous dispersion, wherein the bismuth source is any one of bismuth nitrate pentahydrate, bismuth chloride and bismuth subcitrate, The sulfur source is any one of carbon disulfide, thiourea, sodium sulfide and sodium thiosulfate, the concentration of the bismuth source is 0.05-6 mg / mL, and the molar ratio of the sulfur source and the bismuth source is S:Bi=0.1-5;

[0033] The third step: transfer the mixed water dispersion into the reaction kettle, grow bismuth-based photocatalytic nanoparticles on the surface...

Embodiment 1

[0039] Weigh 10mg Ti 3 C 2 T x Add 20mL of water, ultrasonically disperse evenly, configure Ti 3 C 2 T x Water dispersion, add 10mg bismuth nitrate pentahydrate (bismuth source), 5mg thiourea (sulfur source), 3mg oxalic acid (reducing agent) to Ti 3 C 2 T x In the aqueous dispersion (that is, the MXene aqueous dispersion), stir evenly for five minutes and then transfer them to a 50mL stainless steel reactor, react at 40°C for 1 hour, and cool naturally after the end; 3 C 2 T x / bismuth sulfide nanoparticle composite dispersion (i.e. MXene / bismuth-based photocatalytic nanoparticle composite dispersion) is divided into two parts, 10mL each, and one part is poured on the polyethersulfone (PES) ultrafiltration membrane substrate (porous support layer), vacuum-filtered to form a film, and placed in a vacuum oven to dry for later use. The drying time was 0.5 hour, and the drying temperature was 40°C.

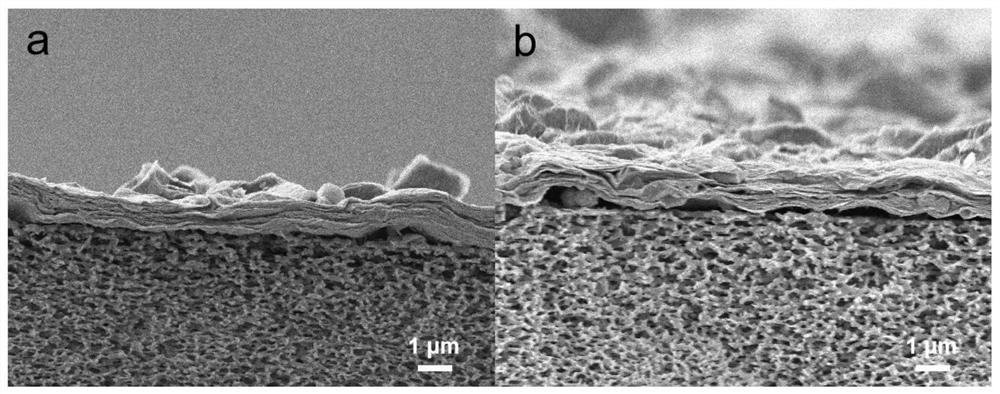

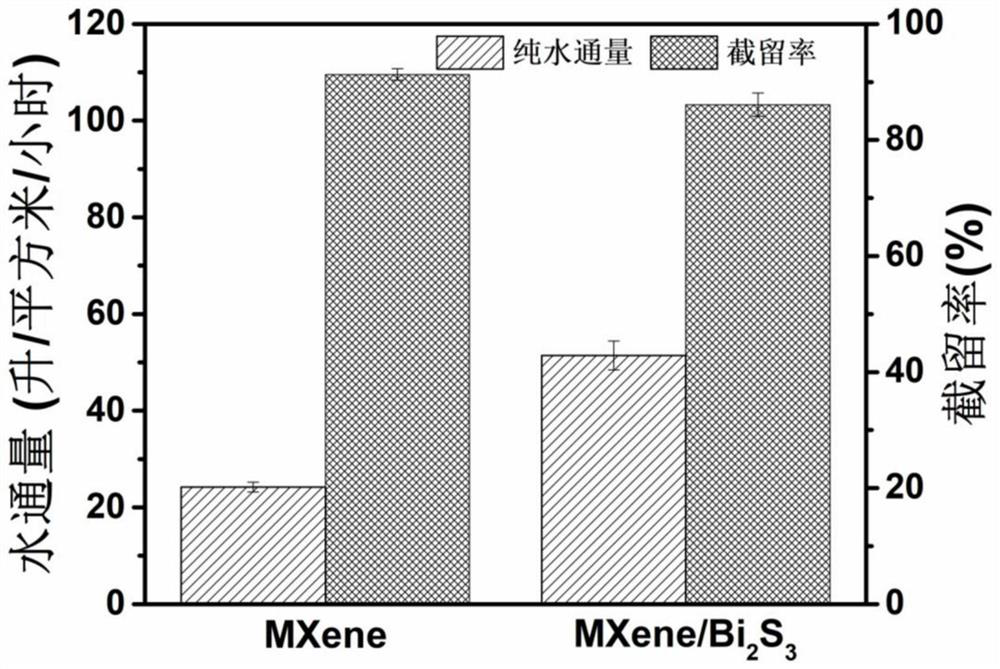

[0040] The Ti prepared in this example 3 C 2 T x / Bi 2 S 3 The pho...

Embodiment 2

[0042] Weigh 10mg Ti 3 C 2 T x Add 20mL of water, ultrasonically disperse evenly, configure Ti 3 C 2 T x Water dispersion, add 35mg bismuth nitrate pentahydrate (bismuth source), 20mg thiourea (sulfur source), 15mg oxalic acid (reducing agent) to Ti 3 C 2 T x In the aqueous dispersion (that is, the MXene aqueous dispersion), stir evenly for five minutes and transfer them to a 50mL stainless steel reactor, react at 120°C for 12 hours, and cool naturally after the end; 3 C 2 T x / bismuth sulfide nanoparticle composite dispersion (i.e. MXene / bismuth-based photocatalytic nanoparticle composite dispersion) is divided into two parts, 10mL each, and one part is poured on the polyethersulfone (PES) ultrafiltration membrane substrate (porous support layer), vacuum-filtered to form a film, and placed in a vacuum oven to dry for later use. The drying time was 1 hour and the drying temperature was 60°C.

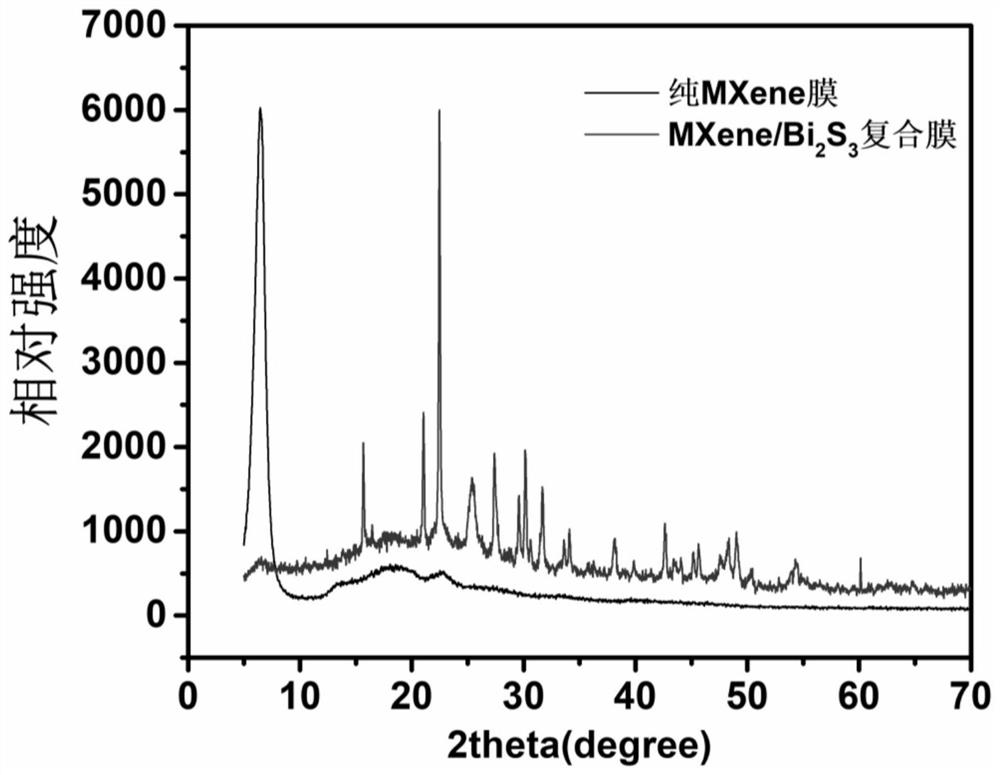

[0043] By scanning electron microscope (SEM), X-ray diffraction analysis (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com