Tubular type ceramic filter element and preparation method thereof

A ceramic filter element and tubular technology, which is applied in the field of tubular ceramic filter element and its preparation, can solve the problem of low water flux, achieve the effect of expanding the application range and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

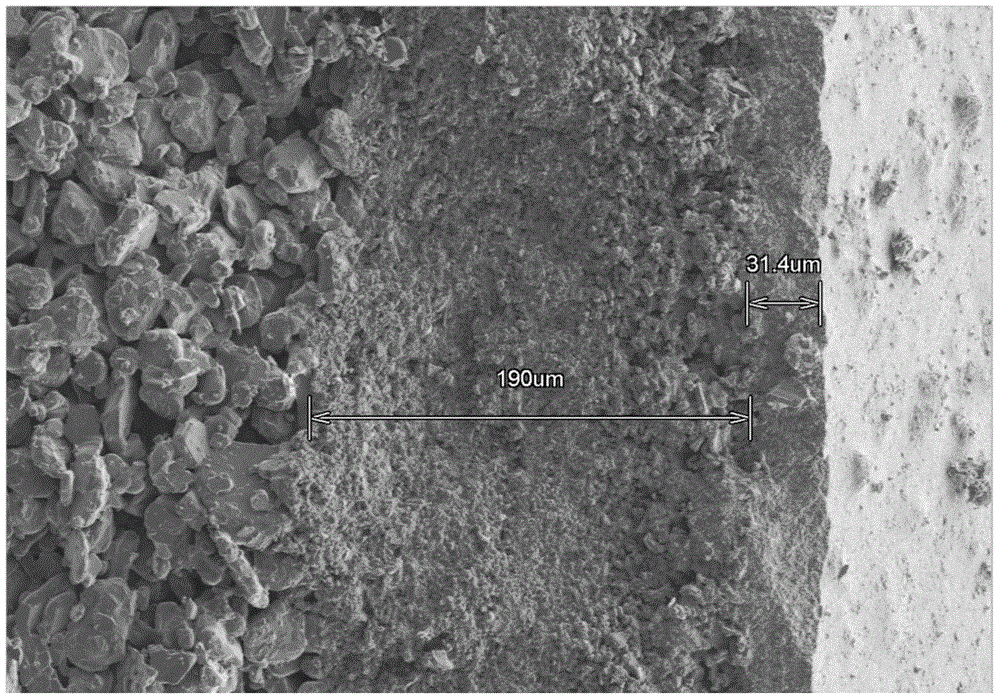

Image

Examples

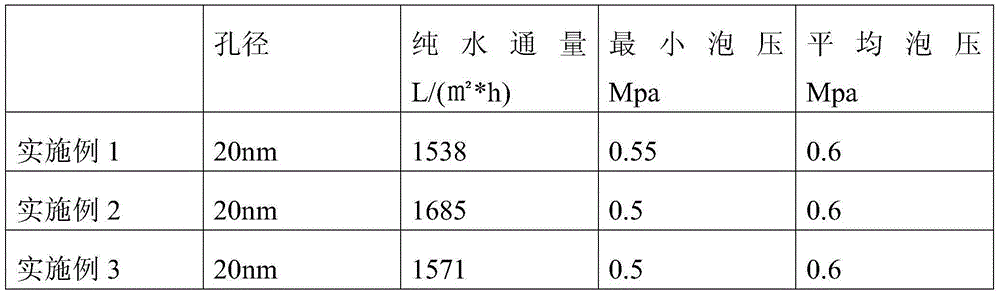

Embodiment 1

[0033] (1) Prepare the membrane transition layer; the weight ratio of the raw materials for the membrane transition layer is as follows: alumina powder (average particle size: 1.2-1.8um) 20kg, calcium nitrate 0.38kg, magnesium nitrate 0.4kg, yttrium nitrate 0.46kg, zirconium nitrate 1.95kg, 0.2kg of lanthanum nitrate, 0.56kg of superfine titanium dioxide powder, 1.6kg of superfine silica powder, 0.46kg of polyvinyl alcohol, 0.48kg of methyl cellulose, 0.25kg of gum arabic powder, 0.048kg of tributyl phosphate, Stearic acid monoglyceride 0.32kg, water 80kg.

[0034] After fully stirring evenly, let it stand for 1-3 days for later use, use a film coating machine to coat the film on the tubular support substrate, dry it at 120°C, and put it into a kiln at 1300°C for sintering.

[0035] (2) Prepare the membrane separation layer; the weight ratio of the raw materials for the membrane separation layer is as follows: ultrafine high-purity zirconia powder (average particle size 0.25-0...

Embodiment 2

[0038] (1) Prepare the membrane transition layer; the weight ratio of the raw materials for the membrane transition layer is as follows: alumina powder (average particle size: 1.2-1.8um) 100kg, calcium nitrate 1.8kg, magnesium nitrate 1.8kg; yttrium nitrate 0.8kg, zirconium nitrate 1.8kg, lanthanum nitrate 1kg, superfine titanium dioxide powder 2kg, superfine silica powder 3kg, polyvinyl alcohol 2kg, methylcellulose 5.5kg, gum arabic powder 0.25kg, tributyl phosphate 0.6kg, monostearic acid Glyceride 1.2kg, water 250kg.

[0039] After fully stirring evenly, let it stand for 1-3 days for later use, use a film coating machine to coat the film on the tubular support substrate, dry it at 120°C, and put it into a kiln at 1500°C for sintering.

[0040] (2) Prepare the membrane separation layer; the weight ratio of the raw materials for the membrane separation layer is as follows: 100kg of ultra-fine high-purity zirconia powder (average particle size 0.25-0.45um), 12.3kg of calcium n...

Embodiment 3

[0043] (1) Prepare the membrane transition layer; the weight ratio of the raw materials for the membrane transition layer is as follows: alumina powder (average particle size: 1.2-1.8um) 10kg, calcium nitrate 1.2kg, magnesium nitrate 1.2kg; yttrium nitrate 0.1kg, zirconium nitrate 1.32kg, 0.8kg of lanthanum nitrate, 1.3kg of superfine titanium dioxide powder, 1.4kg of superfine silica powder, 0.9kg of polyvinyl alcohol, 0.3kg of methyl cellulose, 0.25kg of gum arabic powder, 0.6kg of tributyl phosphate, Stearic acid monoglyceride 1.2kg, water 30kg.

[0044] After fully stirring evenly, let it stand for 1-3 days for later use, use a film coating machine to coat the film on the tubular support substrate, dry it at 120°C, and put it into a kiln at 1350°C for sintering.

[0045](2) Prepare the membrane separation layer; the weight ratio of the raw materials for the membrane separation layer is as follows: ultrafine high-purity zirconia powder (average particle size 0.25-0.45um) 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com