Nanocellulose-assisted preparation method of high-content graphene flexible conductive composite membrane

A nanocellulose and ene flexible technology, applied in the field of graphene and nanocellulose, can solve the problems of low conductivity and low graphene content, and achieve the effect of high conductivity, good strength and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

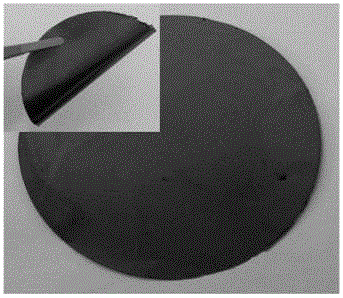

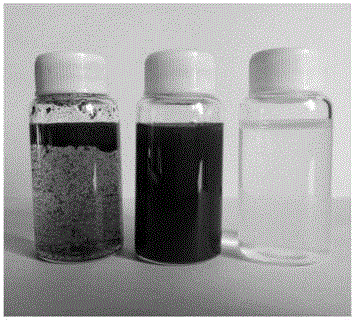

[0025] Such as figure 2 The graphene / nanocellulose composite film prepared in this embodiment is shown, wherein the nanocellulose is obtained by chemically hydrolyzing flax fibers. Add 0.02g of nanocellulose powder to an Erlenmeyer flask containing 20g of water, stir for 0.5h, and then ultrasonically treat it at 800W for 0.5h to obtain a dispersion of nanocellulose (such as figure 1 (Shown), then add 0.98g graphene powder, the mixed solution is ultrasonically treated at 100W power for 12h until the dispersion is uniform, then the mixed solution is slowly poured into a petri dish, and placed in a drying box at a temperature of 80 ℃ to dry When all the water is evaporated, the film is removed from the petri dish to obtain a composite film with a graphene content of 98 wt.%, and the electrical conductivity of the composite film is 198 S / cm.

Embodiment 2

[0027] In the graphene / nanocellulose composite film prepared in this embodiment, the nanocellulose is obtained by chemically hydrolyzing wood pulp fibers. Add 0.05g of nanocellulose powder into an Erlenmeyer flask containing 50g of water, stir for 0.5h and then ultrasonically treat for 0.5h at 800W power to obtain a dispersion of nanocellulose, then add 0.95g of graphene powder and stir. The mixed solution was subjected to ultrasonic treatment under 100W power for 10 hours, then slowly poured the mixed solution into a petri dish, and dried it in a drying box at a temperature of 60℃ until all the water was evaporated, and then peeled off the membrane from the petri dish to obtain The conductivity of the composite film with a graphene content of 95wt.% is 185S / cm.

Embodiment 3

[0029] In the graphene / nanocellulose composite film prepared in this embodiment, the nanocellulose is obtained by chemically hydrolyzing the husk fibers of Astragalus glabra. Add 0.1g of nano-cellulose powder into an Erlenmeyer flask containing 100g of water, stir for 12h and then ultrasonically treat for 12h at a power of 100W to obtain a dispersion of nanocellulose, then add 0.9g of graphene powder and stir the mixture After ultrasonic treatment at 800W power for 2h, then slowly pour the mixed solution into a petri dish, and place it in a drying oven at 40℃ to dry until all the water is evaporated, then peel off the film from the petri dish to obtain graphene The conductivity of the composite membrane with a content of 90wt.% is 169S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com