Optical fiber Fabry-Perot sound pressure sensor manufacturing method based on graphene membrane and measuring method and device thereof

A sound pressure sensor, graphene film technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of low sensor sensitivity, and achieve the effects of small size, high reliability and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through implementation. Other aspects, features and advantages of the present invention will become clear through the detailed description.

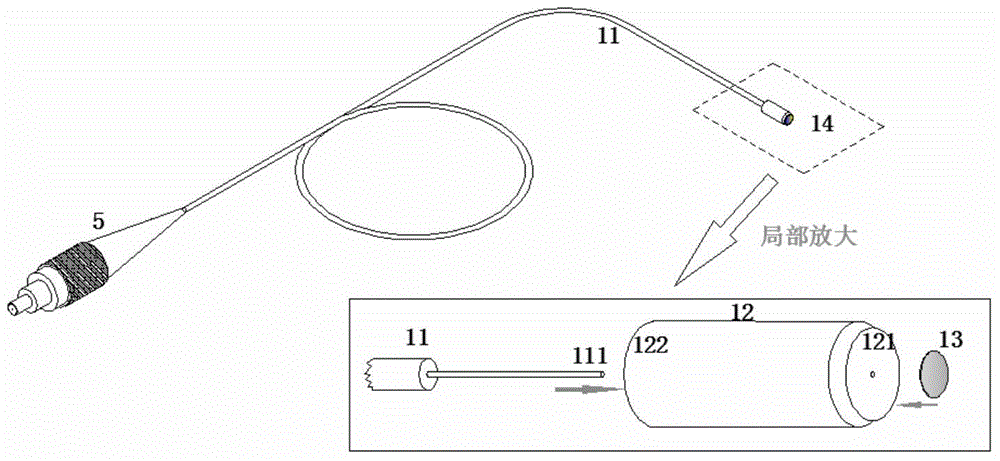

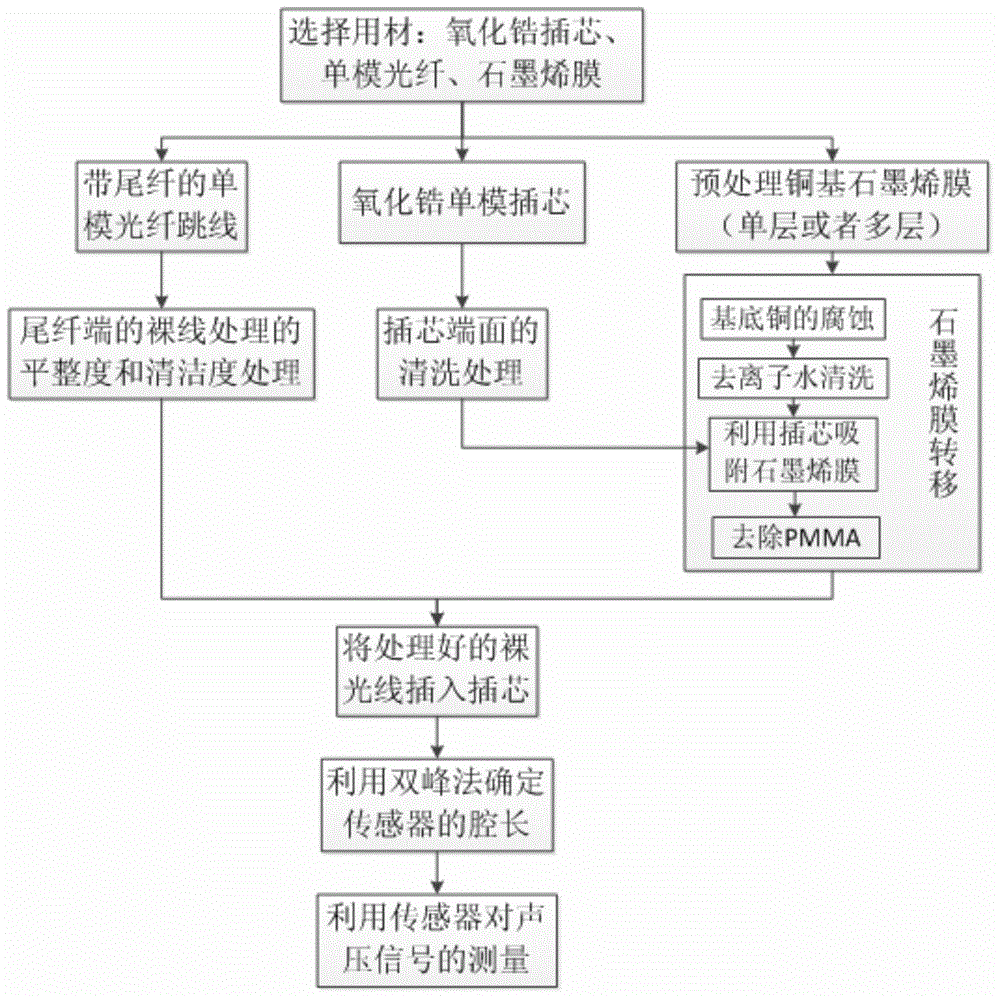

[0031] figure 1 It is a structural schematic diagram of the fiber optic acoustic pressure sensor based on the graphene film of the present invention. The sensor probe part 14 is mainly composed of a single-mode optical fiber 11 , a zirconia single-mode ferrule 12 and a graphene film 13 . The single-mode optical fiber 11 is an optical fiber connector with a single-mode pigtail. The single-mode pigtail is a single-mode bare optical fiber with an outer diameter of 125±0.7 μm and a core of 10.4±0.5 μm. The zirconia single-mode ferrule 12 is a single-mode ceramic ferrule with an outer diameter of 2.5 mm, an inner diameter of 126 ± 1 μm, and a leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com