Graphene film for light efficient electromagnetic shielding and preparation method thereof

A graphene film, electromagnetic shielding technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of different shielding performance, high shielding performance, low density, etc., achieve strong electromagnetic shielding performance, and improve electrical conductivity. , the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of Graphene Oxide without Fragmentary Super Large Sheets

[0039] Example 1-1

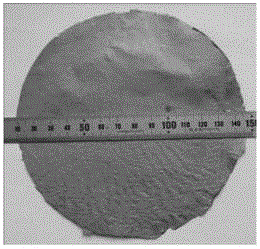

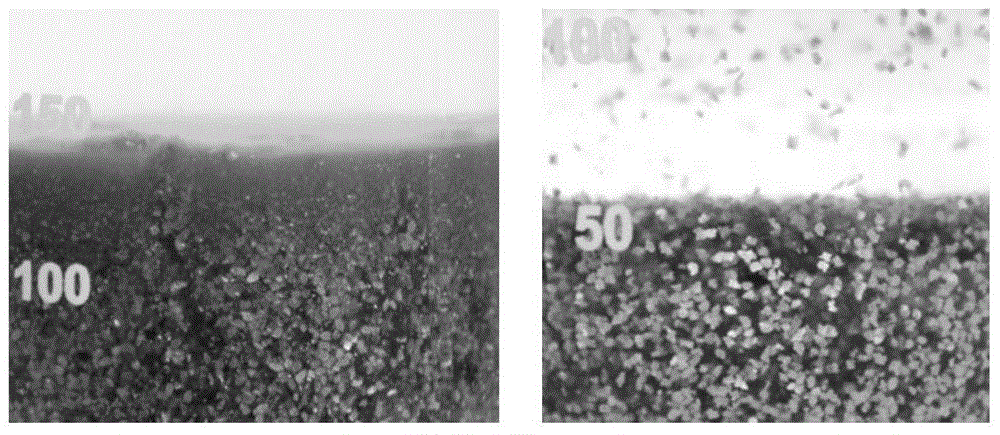

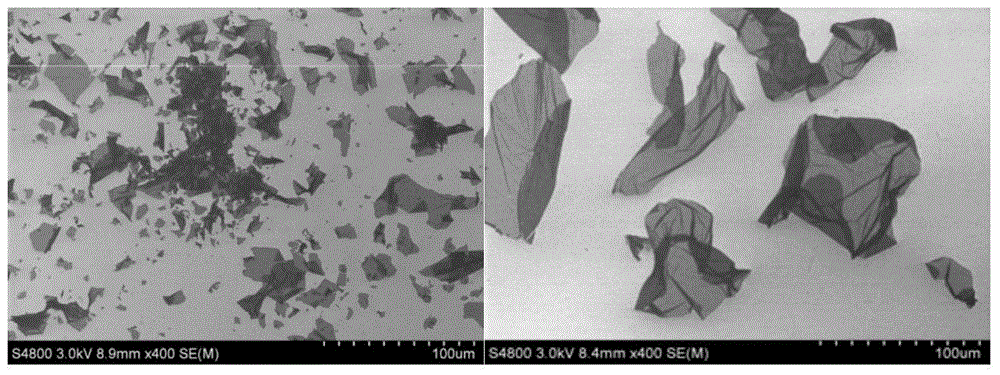

[0040] (1) Slowly add potassium permanganate into the rapidly stirring concentrated sulfuric acid at -10°C. After fully dissolving, add graphite, stir slowly at 60 rpm for 2 hours, then stop stirring. Reaction 6h, obtain the graphite oxide crystal of wide distribution respectively; As figure 1 As shown, there are more fragments in the graphite oxide wafers obtained under the two temperatures, which makes its corresponding graphene oxide also have a lot of fragments ( figure 2 ).

[0041] (2) The reaction solution obtained in step 1 is diluted with concentrated sulfuric acid (the dilution factor can be any multiple, and the present embodiment is diluted about 10 times), and the graphite oxide crystals are filtered out with a titanium alloy mesh sieve with a 150um aperture (140 mesh) (Reaction solution recovery), and slowly pour into rapidly stirred ice water relativ...

Embodiment 2

[0049] Embodiment 2: Using the non-fragmented super-large graphene oxide prepared in embodiment 1 to prepare a light and efficient graphene film for electromagnetic shielding.

[0050] Using 0.1mg / ml graphene oxide aqueous solution as raw material, adding mass fraction of 0.1% ammonium bicarbonate to the solution, after ultrasonic dispersion, the graphene oxide film was prepared by pouring and drying method, and then reduced with hydrazine hydrate, and then the reduced The graphene film is heated up gradually to 500 degrees at 1 degree per minute in an inert gas atmosphere, and kept for 0.5 hours. Gradually increase the temperature at 2°C / min to 3000°C for 0.5 hours to obtain a lightweight and efficient graphene film material for electromagnetic shielding.

[0051] The light and high-efficiency graphene film for electromagnetic shielding has a density of 0.005-0.1g / cm 3 , with holes aligned along the in-plane orientation of graphene and partially overlapped, such as Figure ...

Embodiment 3

[0055] Embodiment 3: Using the non-fragmented super large graphene oxide prepared in embodiment 1 to prepare a light and efficient graphene film for electromagnetic shielding.

[0056] Using 100mg / ml graphene oxide aqueous solution as raw material, add 5% urea in mass fraction to the solution, after ultrasonic dispersion, prepare graphene oxide film by scraping film drying method, then reduce it with hydrazine hydrate, and then reduce the reduced graphite The graphene films were heat-treated in the heat treatment methods shown in Table 1 to Table 3 under an inert gas atmosphere to obtain light-weight and high-efficiency graphene film materials for electromagnetic shielding.

[0057] Table 1: Different heating conditions in the first step

[0058]

[0059] It can be seen from Table 1 that the performance of this material is mainly determined by two aspects. One is the repair of the graphene oxide sheet structure inside the material, that is, the loss of functional groups and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com