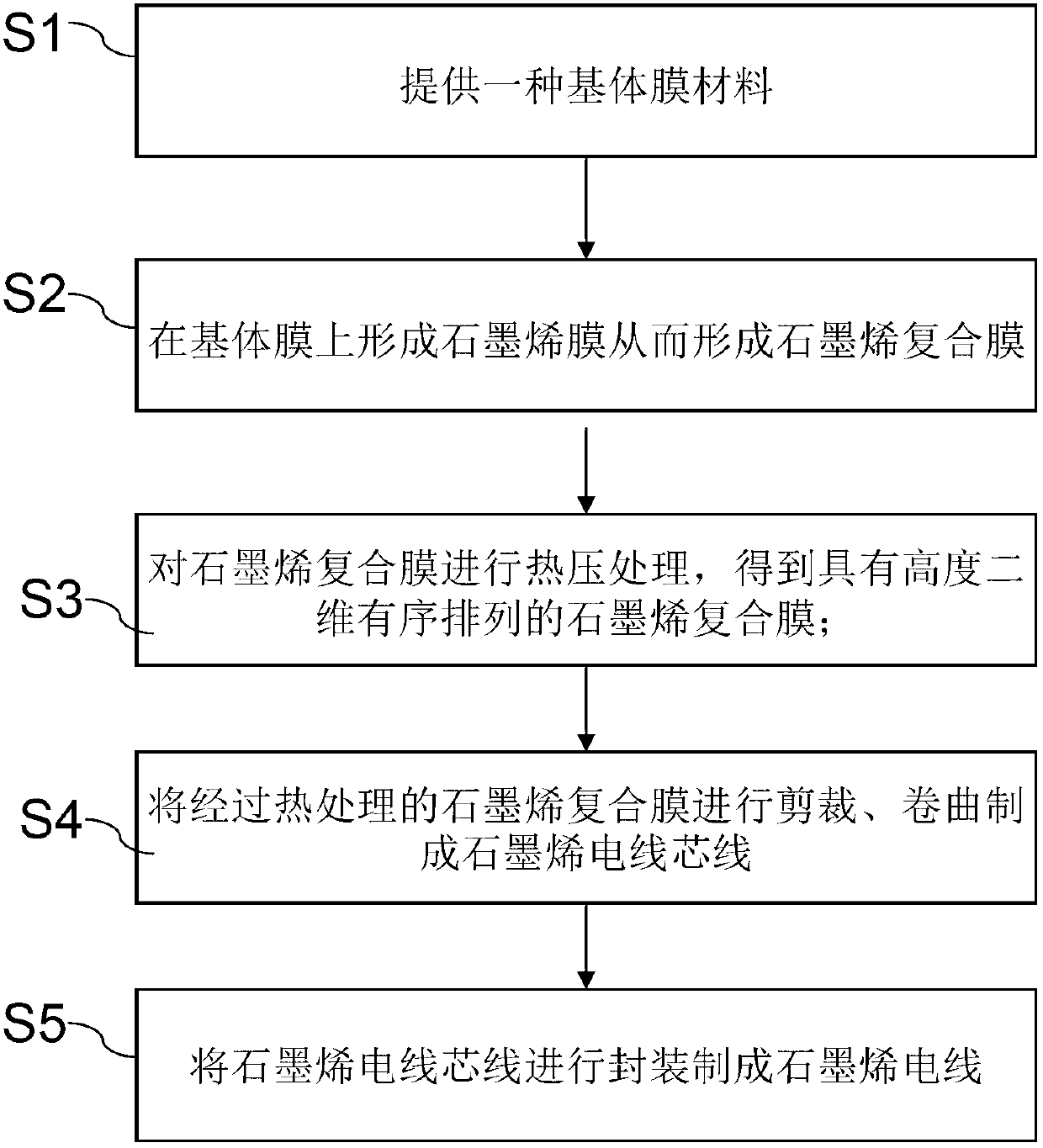

Method for preparing graphene wire and cable

A technology of graphene and graphene film, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of not fully utilizing the conductive properties of graphene, achieve good chemical stability, fast electron movement speed, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure or characteristic that can be included in at least one implementation of the present invention. "In one embodiment" appearing in different places in this specification does not all refer to the same embodiment, nor is it a separate or selective embodiment that is mutually exclusive with other embodiments.

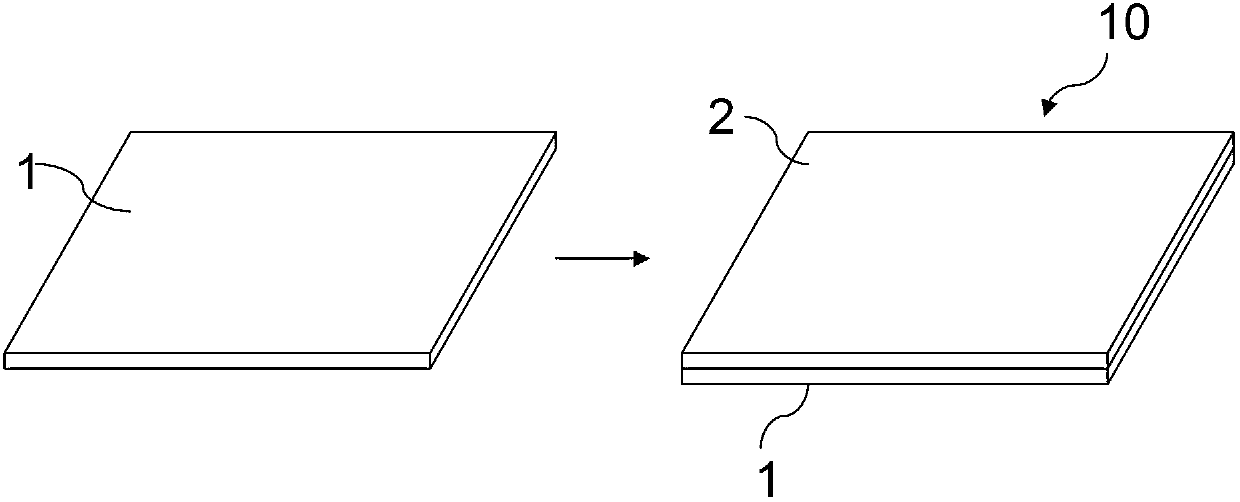

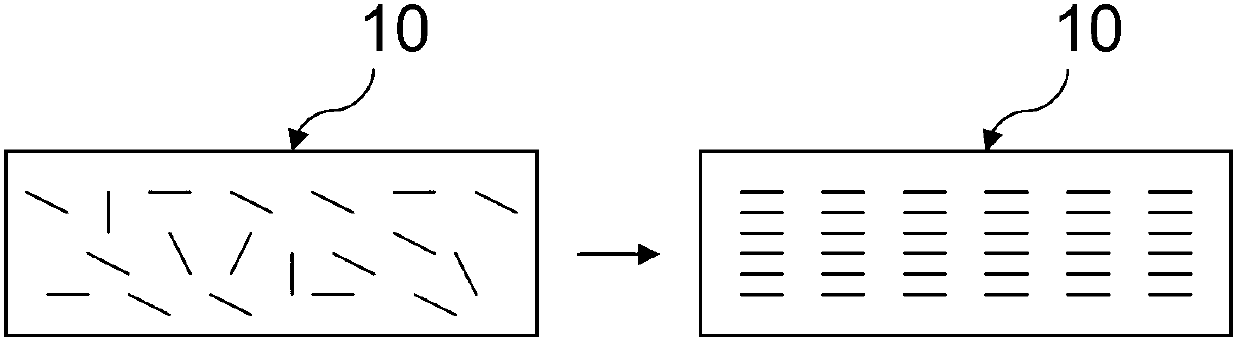

[0034] As mentioned earlier, due to the excellent properties of graphene materials, there is now a technology to use graphene powder materials as conductive core materials, but due to the two-dimensional conductive properties of graphene (ie: the resistance of graphene on a two-dimensional plane Rate is 10 -6 Ω cm, while the resistivity in the Z-axis direction increases rapidly to 10x10 -1 Ω·cm), causing the resistivity of the chaotically stacked graphene powder to drop to 6.6x10 -3 Ω·cm. This greatly affects the conductive properties of graphene. The invention provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com