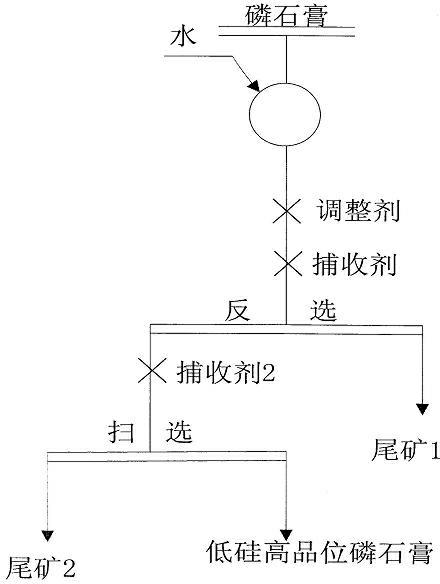

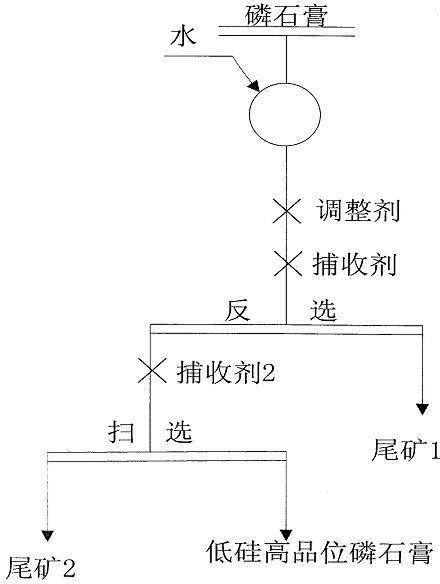

Phosphogypsum reverse flotation, desilication and impurity removal process

A technology of reverse flotation desiliconization and phosphogypsum, which is applied in the field of phosphorus chemical industry, can solve the problems of high acrobatic content, low content and low concentration of CaO in solid decomposition products, reduce environmental pollution, help sustainable development, and extend industries chain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The main chemical composition of the naturally air-dried phosphogypsum is calculated by weight percent: calcium oxide 28.92%, sulfur trioxide 41.25%, silicon dioxide 8.68%, total phosphorus 0.89%, total fluorine 0.29%, moisture 17.52%, acid Insoluble matter 11.47%. Weigh 300 grams of phosphogypsum sample into a 1L flotation tank, add water until the slurry concentration is about 35%, adjust the slurry for 1 minute, add regulator 5kg / t, reverse flotation collector dosage 480g / t, single reverse flotation After 6 minutes, the product in the tank is filtered by a suction machine to obtain a filter cake with a water content of less than 25%, and dried in an oven (temperature 100-200°C) to obtain high-grade gypsum. The main chemical composition is: CaSO 4 Mass fraction 82.06%, silicon dioxide 2.18%, total phosphorus 0.33%, total fluorine 0.12, acid insoluble matter 8.46%.

Embodiment 2

[0023] Embodiment 2: The main chemical composition of the naturally air-dried phosphogypsum is calculated by weight percentage: calcium oxide 28.90%, sulfur trioxide 40.51%, silicon dioxide 10.56%, total phosphorus 0.99%, total fluorine 0.43%, moisture 16.78%, acid Insoluble matter 11.76%. Weigh 300 grams of phosphogypsum sample into a 1L flotation tank, add water until the slurry concentration is about 35%, adjust the slurry for 1 minute, add regulator 6kg / t, reverse flotation collector 520g / t, and perform SLR flotation for 6 minutes , the product in the tank is filtered by a suction machine to obtain a filter cake with a moisture content of less than 25%, and dried in an oven (temperature 100-200°C) to obtain high-grade phosphogypsum. The main chemical composition is: CaSO 4 Mass fraction 81.25%, silicon dioxide 3.87%, total phosphorus 0.42%, total fluorine 0.23, acid insoluble matter 8.86%.

Embodiment 3

[0024] Embodiment 3: the main chemical composition of the naturally air-dried phosphogypsum is calculated by weight percent: calcium oxide 28.53%, sulfur trioxide 39.67%, silicon dioxide 12.34%, total phosphorus 1.25%, total fluorine 0.57%, moisture 17.25%, acid Insoluble matter 12.74%. Weigh 300 grams of phosphogypsum sample into a 1L flotation tank, add water until the slurry concentration is about 35%, adjust the slurry for 1 minute, add 7kg / t of regulator, and use 610g / t of reverse flotation collector Sweep for 6 minutes, then add collector 2 and sweep for 3 minutes, the dosage is 0.8kg / t, the product in the tank is filtered by a suction filter to get a filter cake with a water content of less than 25%, and dried in an oven (temperature 100-200°C) to obtain high-grade Phosphogypsum, the main chemical composition of which is expressed in weight percent: CaSO 4 Mass fraction 84.54%, silicon dioxide 2.64%, total phosphorus 0.26%, total fluorine 0.16, acid insoluble matter 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com