Uncoiling blanking forming method

A technology of uncoiling blanking and blanking, applied in the direction of feeding device, positioning device, storage device, etc., which can solve the problems of low output, huge mold cost, technical difficulties and investment risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

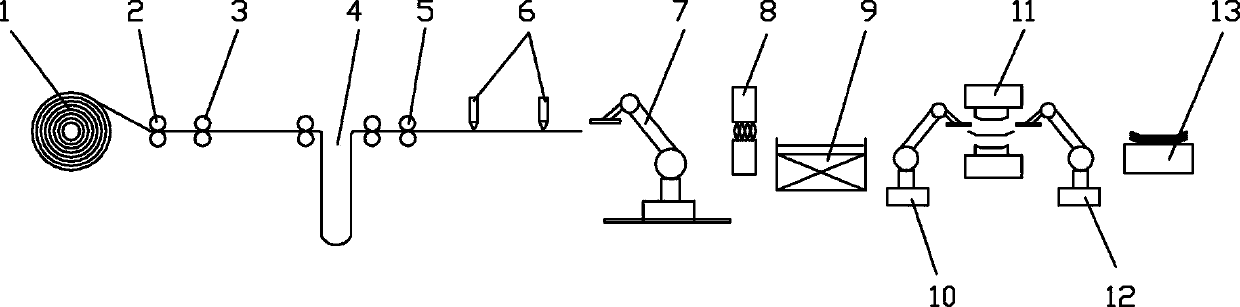

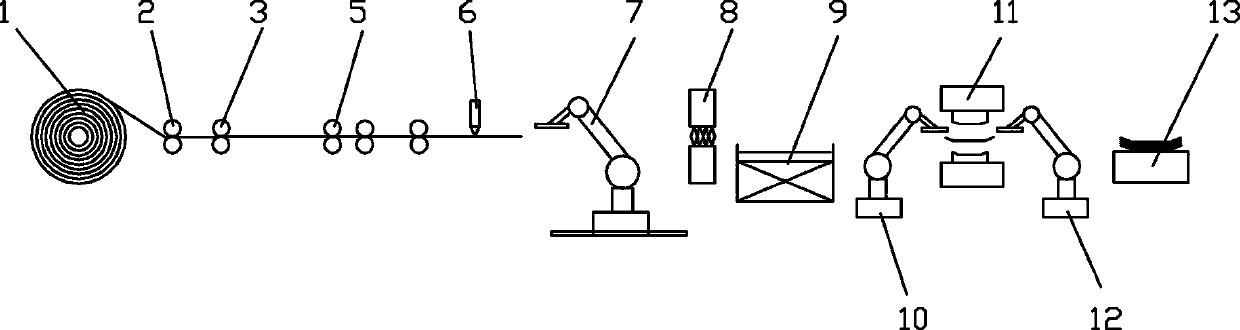

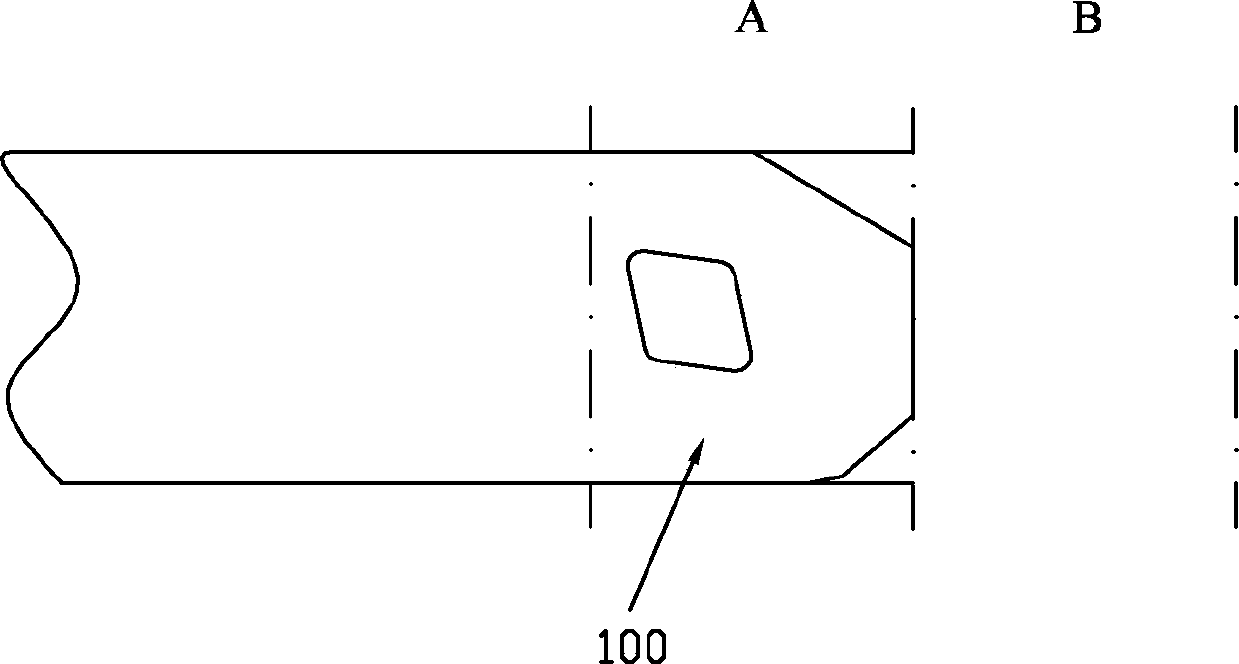

[0034] see figure 1 , a schematic diagram of Embodiment 1 of the present invention. Uncoiling blanking forming method of the present invention, comprises the steps:

[0035] 1) Coil uncoiling

[0036] After the steel coil is uncoiled 1, the steel strip enters the cleaning 2, straightening 3, looper 4, and 5 enters the blanking area through pinching;

[0037] 2) Laser blanking,

[0038] The steel coil enters the blanking area, adopts the laser blanking method, and cuts the material sheet of the required shape through the laser cutting head 6, and the waste material falls and outputs;

[0039] 3) Sheet output

[0040] The blanks are transported by a magnetic telescopic conveyor belt conveyor, and then transported to the stamping process by a manipulator or a robot with an external axis, and the blanks are placed in the stamping die;

[0041] 4) Stamping and forming

[0042] Process the sheet stamping 11 into a workpiece of a certain shape and size, and perform trimming, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com