Method for achieving coal pillar mining replacement through gangue strip filling

A technology of strip filling and coal pillars, which is applied in the direction of filling, safety devices, mining equipment, etc., can solve the problem of inability to realize the comprehensive utilization of power plant fly ash, high salt water and mine gangue, large output of gangue, and limited processing capacity problems such as avoiding ground relocation, reducing ground stacking, and improving recycling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

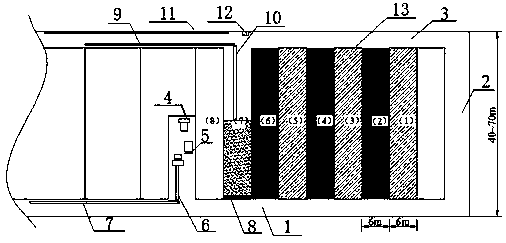

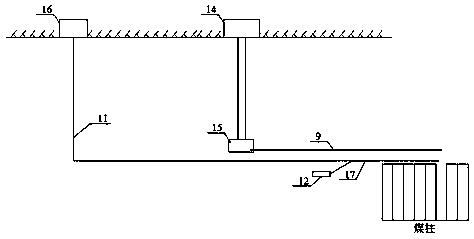

[0022] The following is attached Figure 1-3 The present invention is further described. A method for replacing coal pillars by using gangue strip filling mining, which adopts the scheme of strip filling mining underground in coal mines, and the specific implementation methods are as follows:

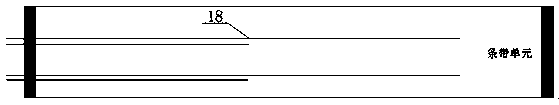

[0023] 1) The transportation lane 1, cutout 2, and air return lane 3 dug in advance form a ventilation circuit to form full negative pressure ventilation. Divide the coal pillar into several mining strips, reasonably determine the length and width of the strip units, and number them in sequence (1), (2), (3), (4), (5)....

[0024] 2) Strip units are mined by continuous miners, and units (1), (3), (5), (7)... are mined sequentially. The continuous miner 4 adopts an automatic coal loading mode, and the reloading and transportation of coal gangue are completed by the mining shuttle car 6 and the belt conveyor 7. When mining coal, local fan ventilation is required. After the strip unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com