A kind of laser processing method of solder mask layer of circuit board

A laser processing method and circuit board technology, applied in printed circuit, metal processing, laser welding equipment, etc., can solve the problems of affecting the product yield, increasing the cost of the enterprise, and long product production cycle, so as to shorten the product production cycle, The effect of simplifying the production process and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

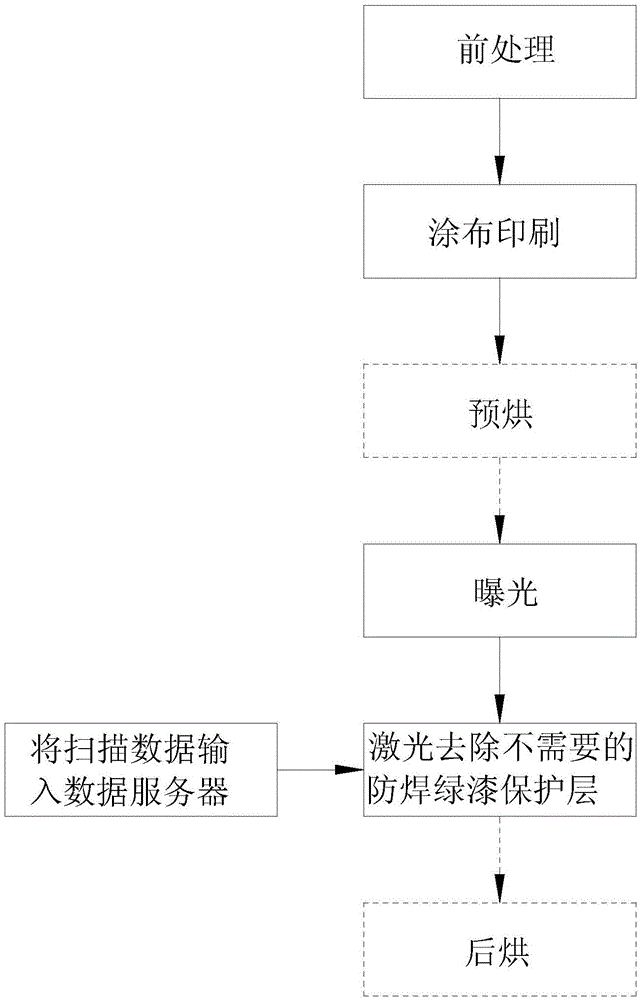

[0040] A kind of laser processing method of circuit board solder resist layer, with reference to figure 1 , the steps are as follows:

[0041] (1), pre-processing

[0042] Alcohol, ethyl acetate, acetone and other cleaning solutions are used to remove oxidation and oil stains on the surface of the circuit board. The pretreatment method of the present invention is the same as the pretreatment process and cleaning solvent used for the circuit board in the prior art.

[0043] (2), coating printing

[0044] Using electrostatic spraying or printing process, the solder resist green paint is coated and printed on the surface of the circuit board.

[0045] Solder resist green paint (liquid photo-induced solder resist, also known as green oil) is a protective layer that is coated on the circuit and substrate of the printed circuit board that do not need to be soldered. The purpose is to protect the formed circuit pattern for a long time. The main components include: epoxy and acryli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com