A multi-band optical exposure system, equipment and method

An optical exposure and exposure subsystem technology, applied in the field of printed circuit boards, can solve the problems of unstable energy output in the effective band, low service life of the coating layer, and increased input costs, etc., to improve the service life and energy utilization rate, Reduce the use cost and maintenance cost, improve the overall production capacity and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

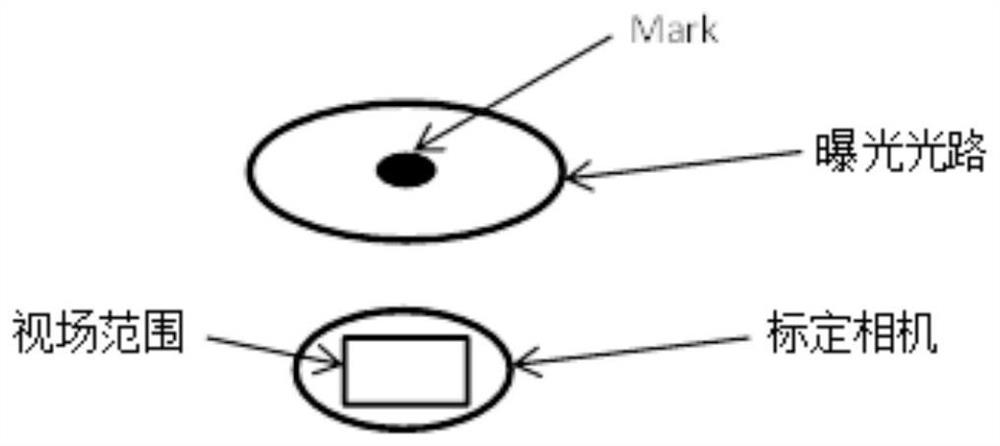

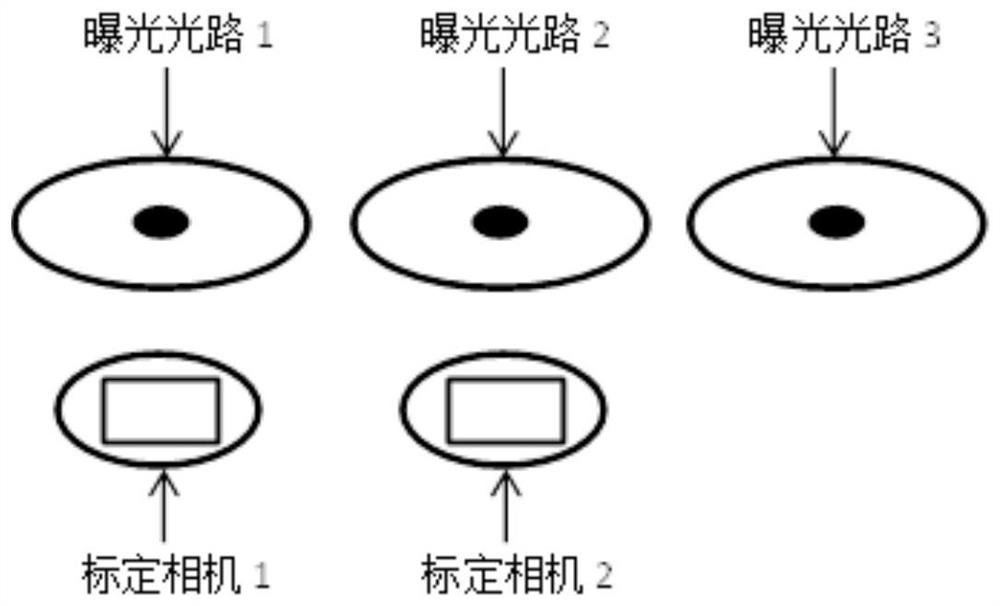

[0034] This embodiment provides a multi-band optical exposure system, the multi-band optical exposure system includes at least two groups of exposure subsystems, a calibration system and a motion platform;

[0035] The exposure subsystem is used to expose the substrate to be exposed; the calibration system is used to calibrate different exposure subsystems and each optical path in each exposure subsystem in a single direction, on a plane or in a spatial position to achieve different exposures The graphics formed by the subsystem when exposing the substrate to be exposed are superimposed at the same position; the motion platform is used to realize the movement of the substrate to be exposed in a single direction, on a plane or in a spatial position;

[0036] Among them, each group of exposure subsystems matches light sources of different wavelength ranges and optical devices corresponding to different wavelength ranges, and each group of exposure subsystems is set in multi-band ...

Embodiment 2

[0039] This embodiment provides a multi-band optical exposure system, the multi-band optical exposure system includes at least two groups of exposure subsystems, a calibration system and a motion platform;

[0040]The exposure subsystem is used to expose the substrate to be exposed; the calibration system is used to calibrate different exposure subsystems and each optical path in each exposure subsystem in a single direction, on a plane or in a spatial position to achieve different exposures The graphics formed by the subsystem when exposing the substrate to be exposed are superimposed at the same position; the motion platform is used to realize the movement of the substrate to be exposed in a single direction, on a plane or in a spatial position;

[0041] Among them, each group of exposure subsystems matches light sources of different wavelength ranges and optical devices corresponding to different wavelength ranges, and each group of exposure subsystems is set in multi-band ...

Embodiment 3

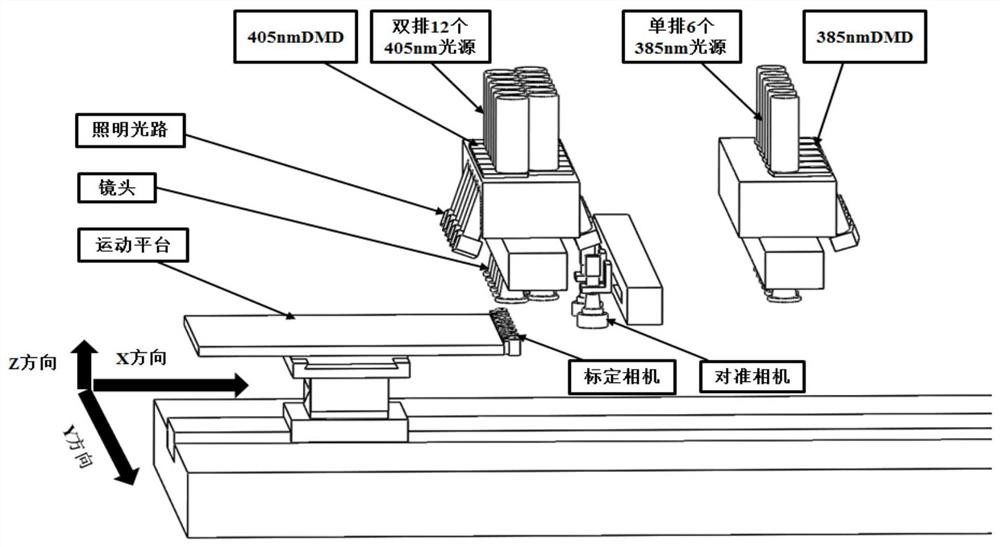

[0049] This embodiment provides a multi-band optical exposure equipment, please refer to figure 1 , the multi-band optical exposure equipment includes the multi-band optical exposure system described in Embodiment 1 or Embodiment 2;

[0050] In this embodiment, the multi-band optical exposure equipment includes two sets of exposure subsystems, and each set of exposure subsystems matches single-wavelength light sources of different wavelengths for illustration:

[0051] Because the wavelength is different, the interval time required for exposing the substrate to be exposed is also different. In order to make the exposure subsystem of the single-wavelength light source matching different wavelengths expose the solder resist ink, there is a time difference, so that the photochemical reaction is more sufficient. The graphics exposed on the composite photosensitive material have better gloss and higher definition, so the two sets of exposure subsystems are arranged at different pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com