A clamping and lifting device

A lifting device and mounting frame technology, applied in the direction of exposure devices, instruments, opto-mechanical equipment, etc. in the photoengraving process, can solve the problems of incompatibility with automation, high-efficiency development requirements, hidden exposure quality hazards, and high labor dependence, and achieve the benefits of Exposure quality, increased exposure speed, and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

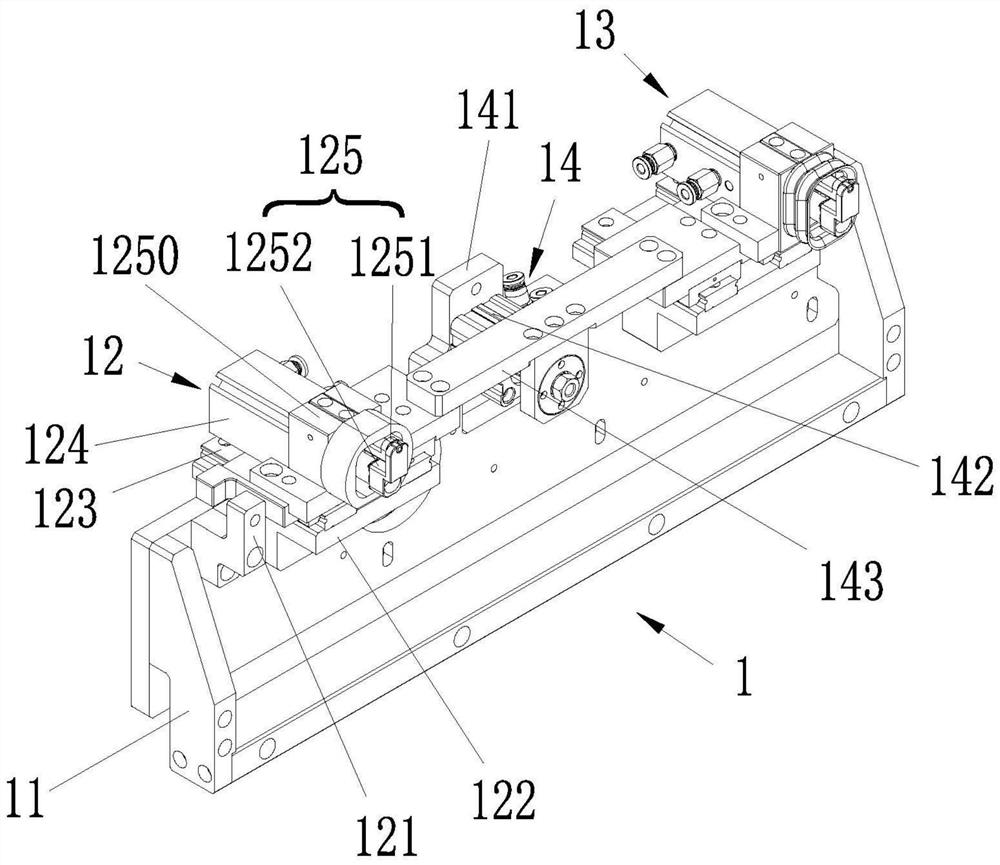

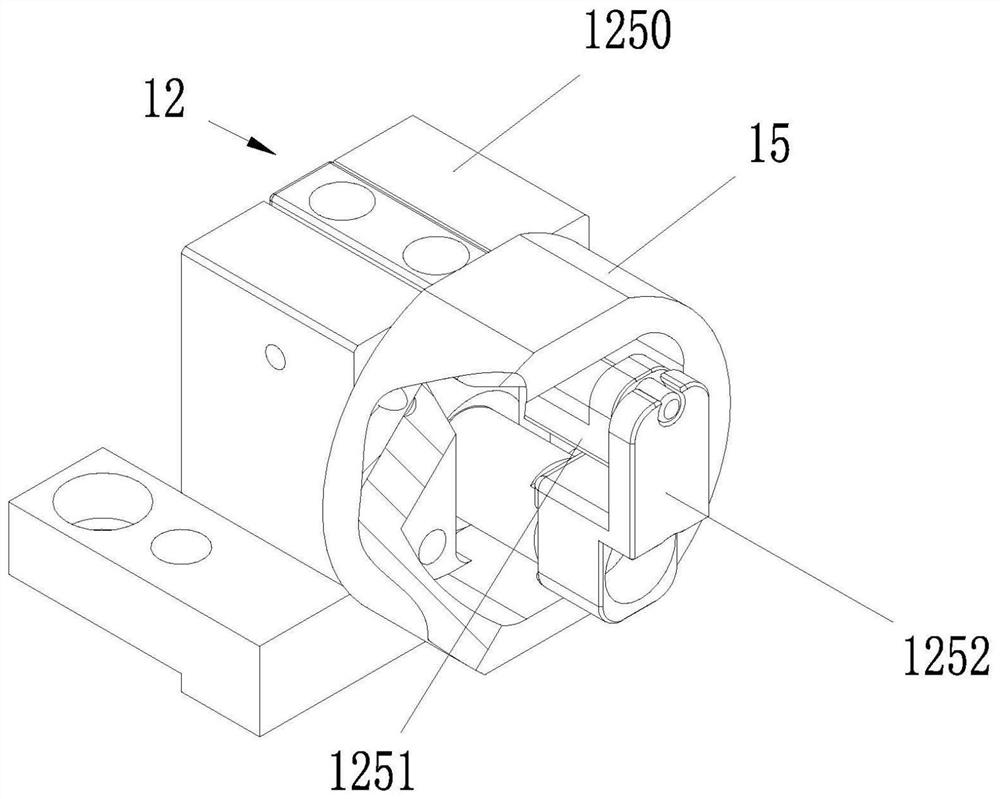

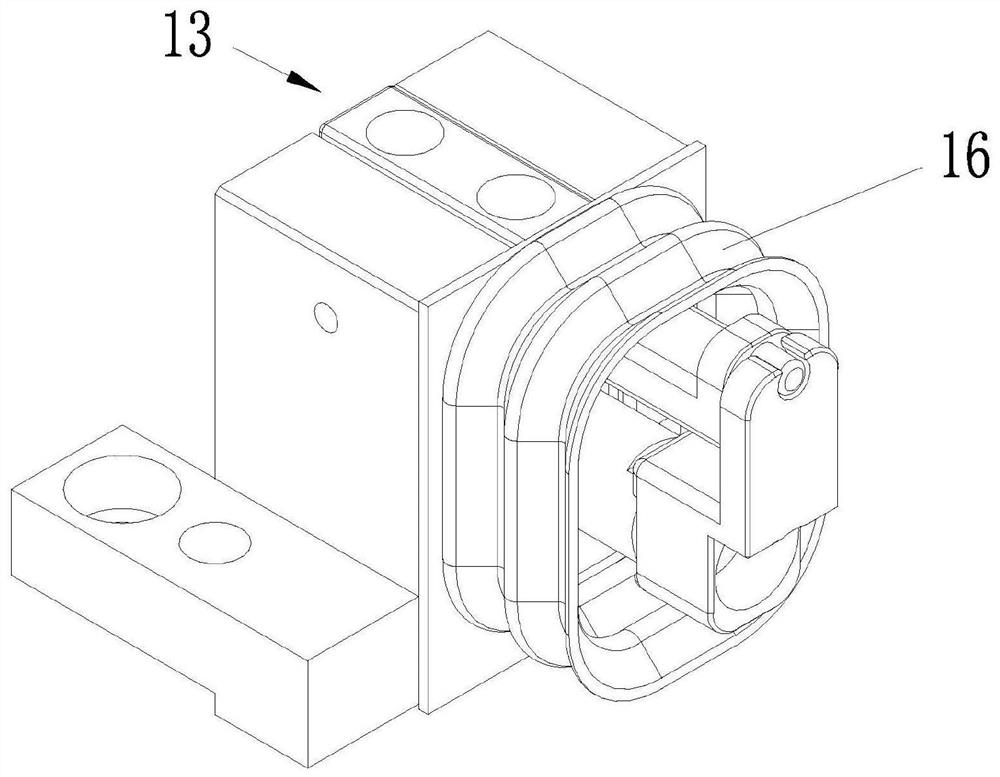

[0030] The specific embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0031] The driver 124 and the actuator 142 in the present invention are both cylinder devices, which are respectively connected to the power source of the pneumatic system (not shown in the figure); in practical applications, the driver 124 and the actuator 142 can be incorporated into the double-sided exposure machine 100 (see Figure 9 ) in the pneumatic system.

[0032] see Figure 7 and Figure 8 , the double-sided exposure machine 100 mentioned in the present invention has a platform 101 under the frame, and the platform 101 under the frame is provided with an exposure area 1011, and the exposure area 1011 is provided with an alignment hole 1012. The semi-finished PCB boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com