A high-speed image exposure method for dmd maskless lithography machine

A technology of maskless lithography and high-speed imaging, which is applied in microlithography exposure equipment, photomechanical equipment, and photolithography process exposure equipment, etc., can solve the problems of large data volume and limit the working efficiency of lithography machines, and achieve high-speed Effects of data transmission, improving DMD image exposure speed, and optimizing exposure control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] For the convenience of description, the relevant technical terms appearing in the specific implementation are explained first:

[0025] DMD (Digital Micromirror Device): digital micromirror device;

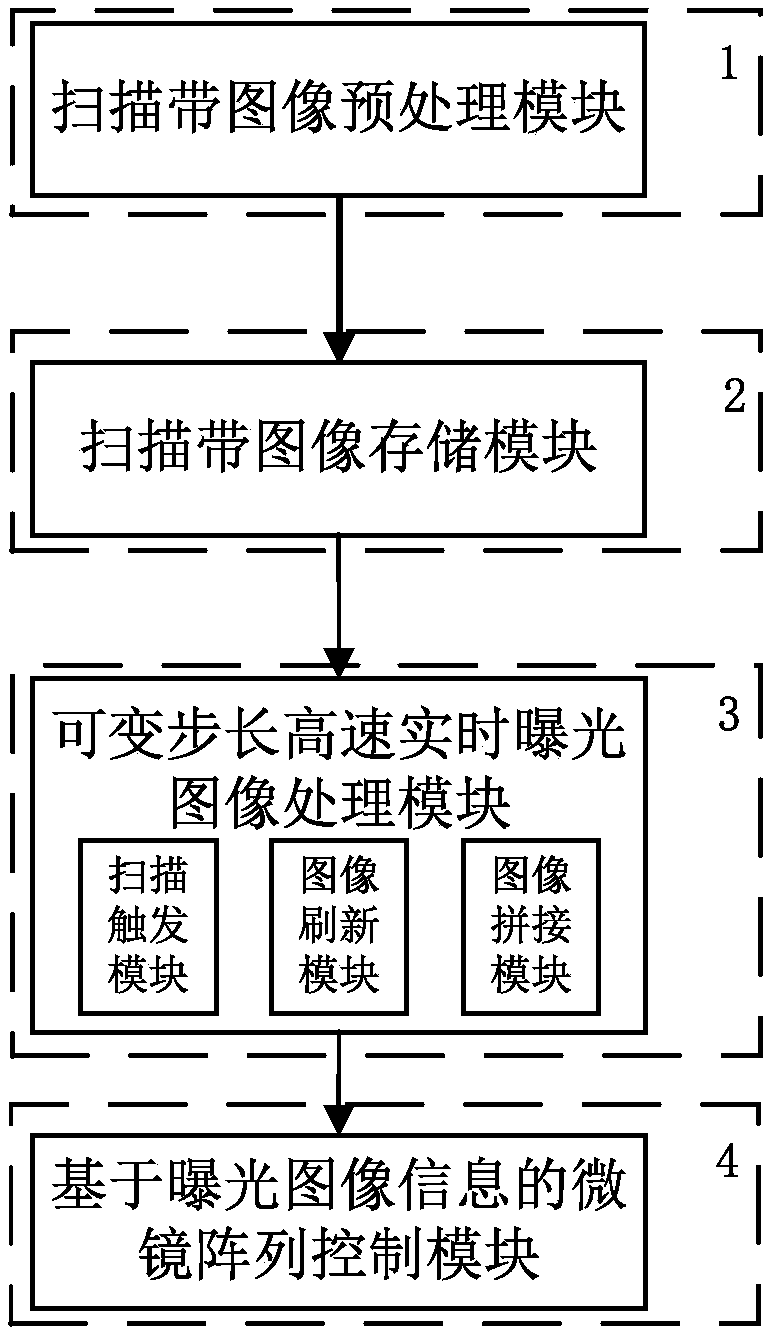

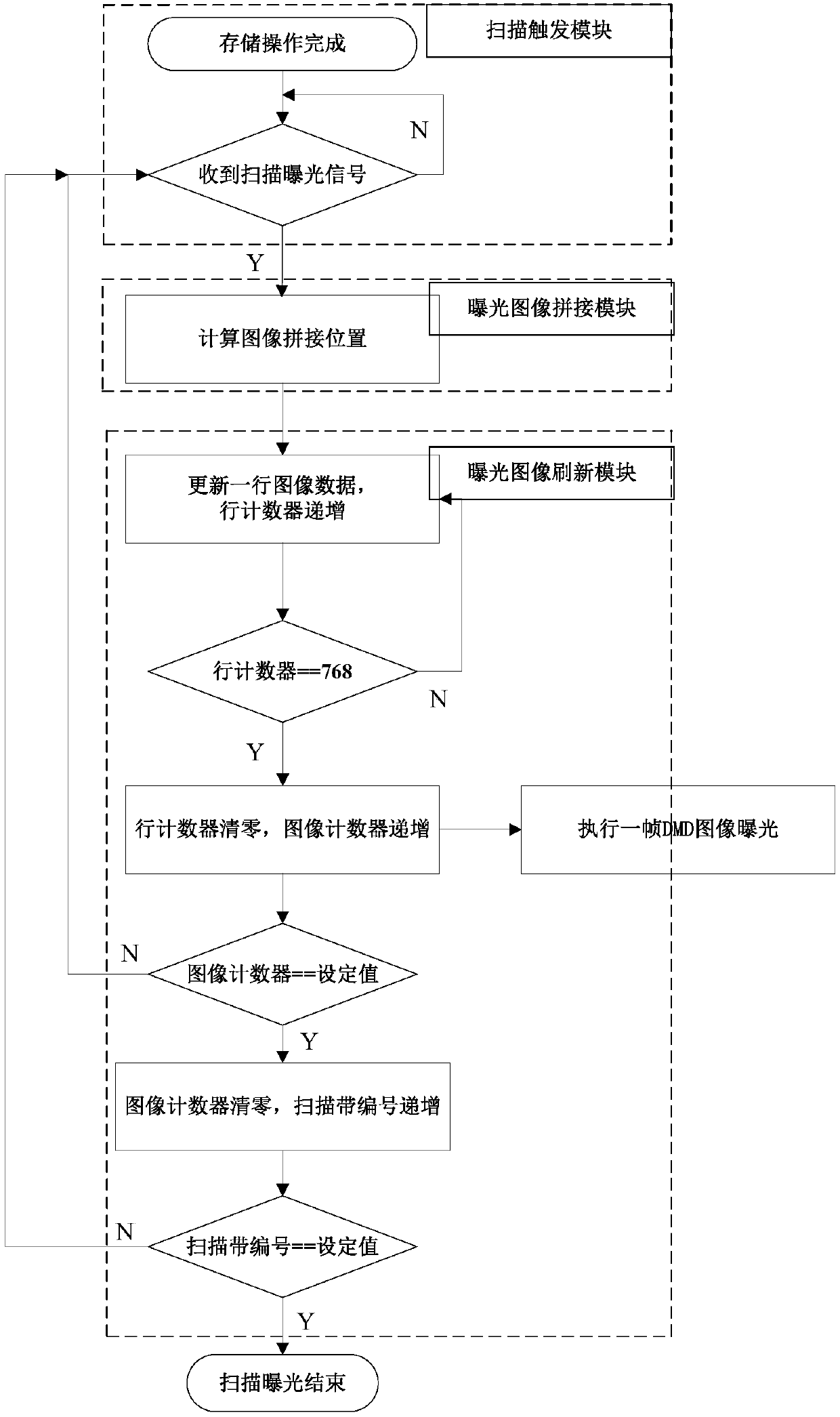

[0026] figure 1 It is a system block diagram of a high-speed image exposure method for a DMD maskless lithography machine.

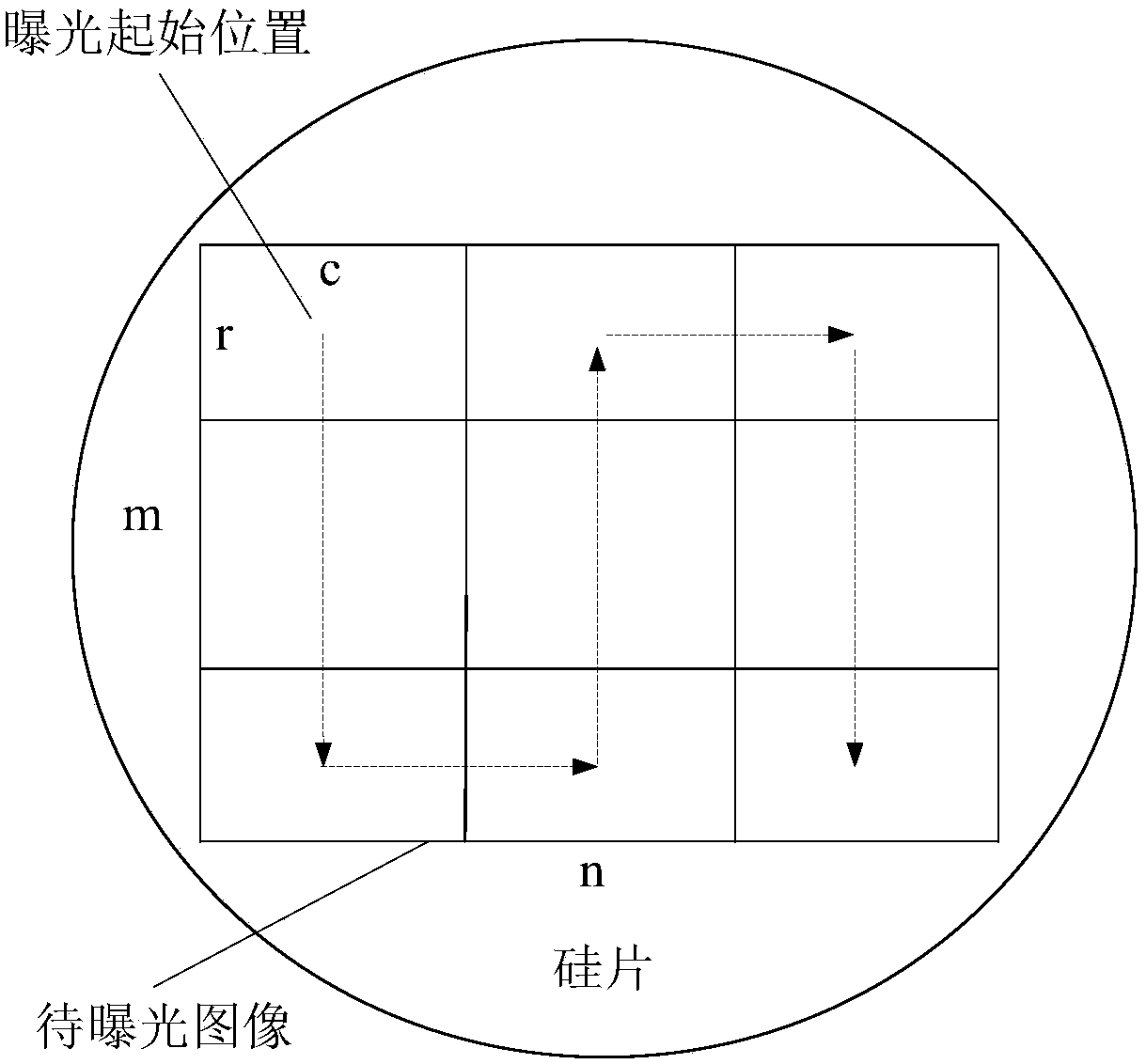

[0027] In this embodiment, the core controller of the control board of the DMD takes Xilinx Virtex-5 type FPGA as an example, and the storage device takes DDR2 as an example, and the original image to be exposed is a bitmap image with a resolution of 10000×10000 As an example, DMD takes the 0.7XGA model as an example, and its resolution is 768×1024. It can be understood that the application of other types of controllers, storage devices, and DMDs is naturally also included in the protection scope of the present invention.

[0028] Combined below as figure 1 As shown, a high-speed image exposure method for a DMD maskless photolithography machine of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com