Exposure mechanism of platemaking machine

A technology of plate-making machines and optical drums, applied in optics, instruments, printing equipment, etc., can solve problems such as low production efficiency, complicated exposure process, and large manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

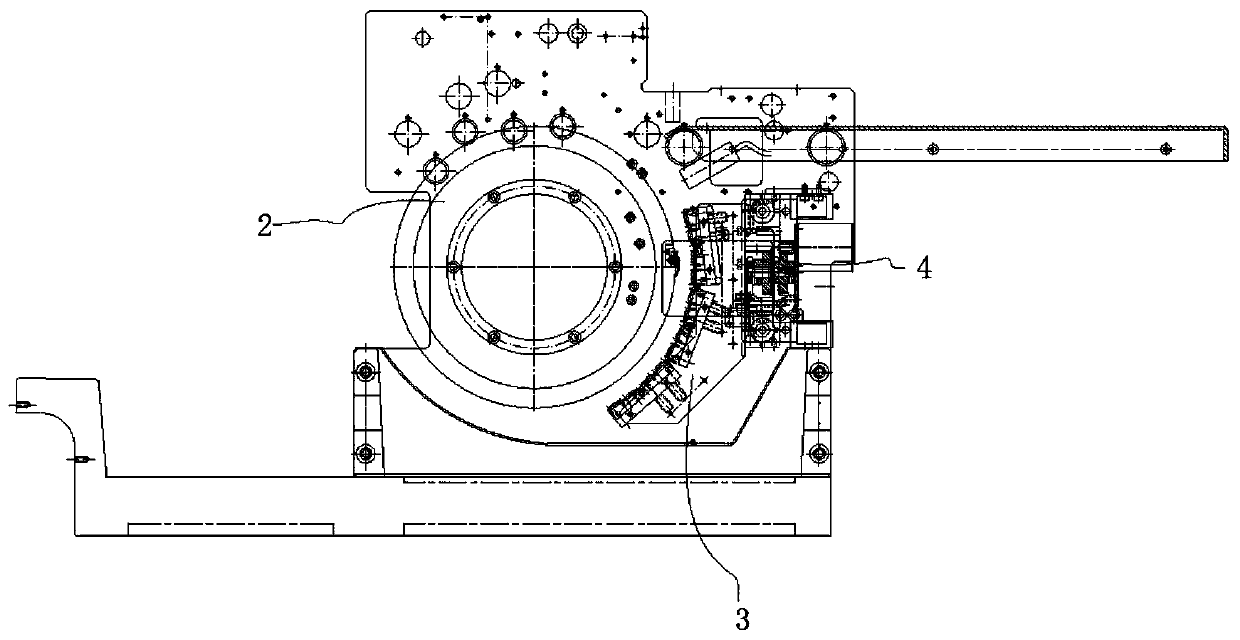

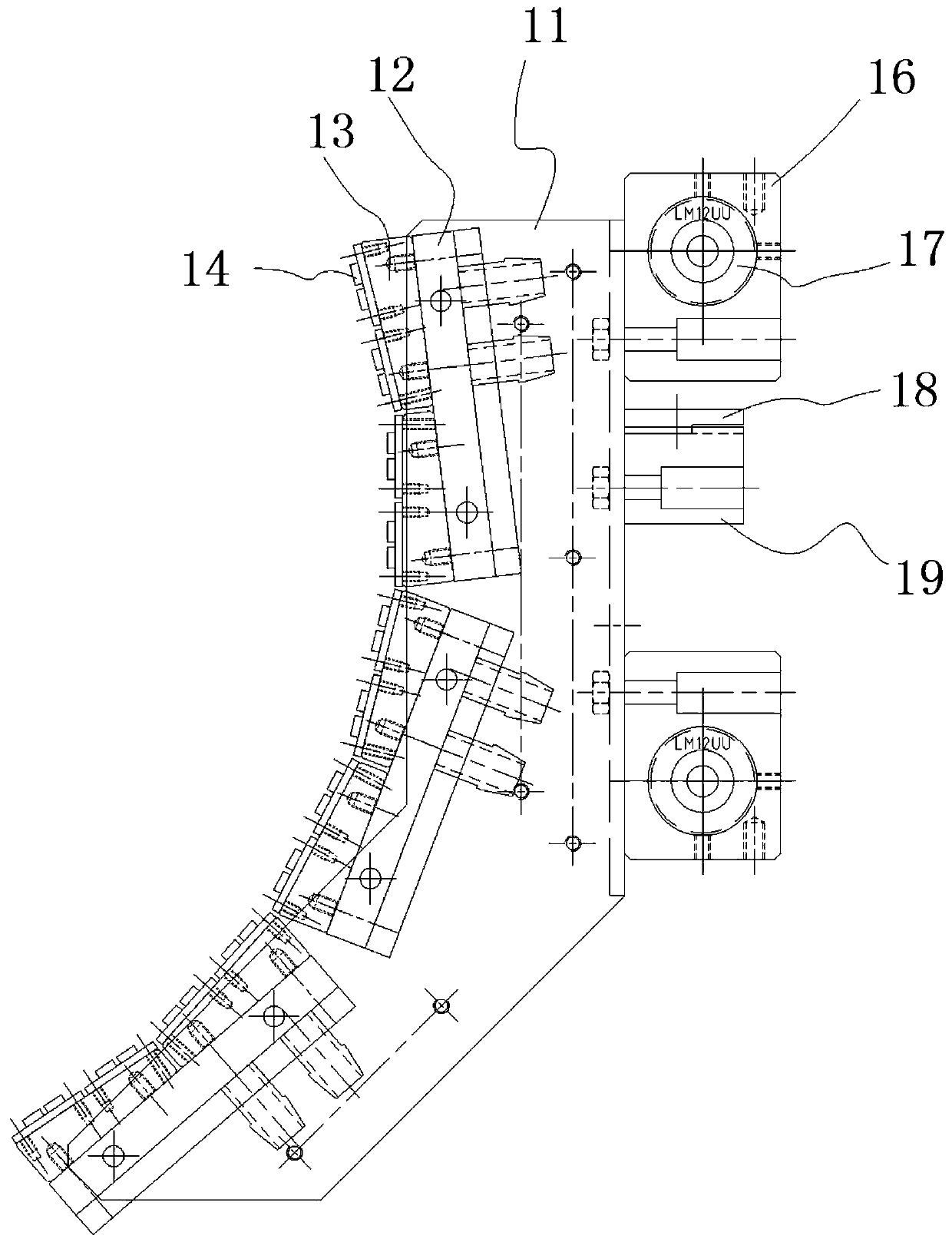

[0017] Embodiment 1: As shown in the figure, an exposure mechanism of a plate-making machine includes a wallboard 1 and a light drum 2. The wallboard 1 is provided with a displaceable actuator assembly 3. Both sides of the wallboard 1 Each end is provided with a transmission assembly 4, the transmission assembly 4 drives the actuator assembly 3 to move, and the actuator assembly 3 is in movable contact with the optical drum 2.

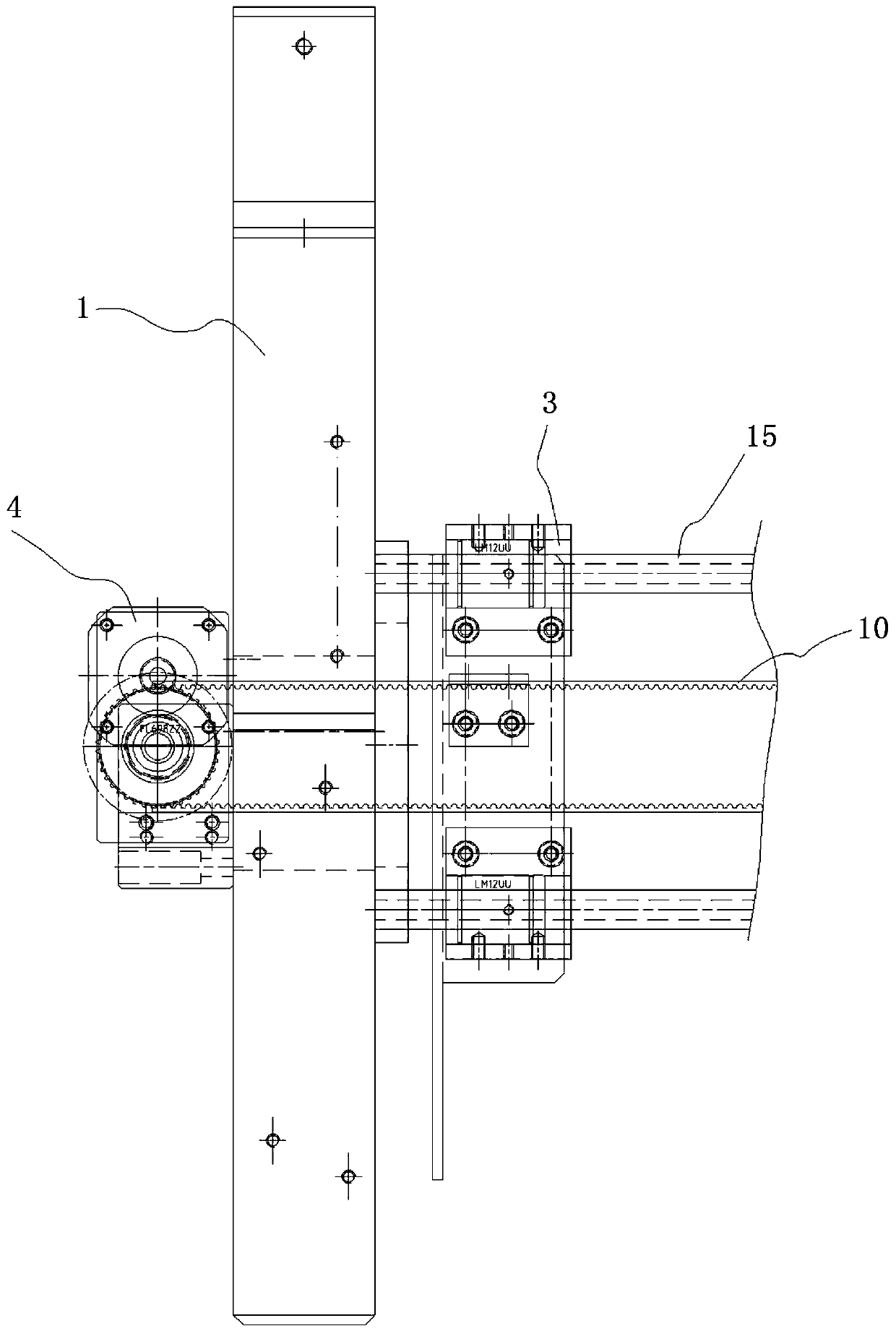

[0018] The transmission assembly 4 includes a transmission frame 6, and a stepping motor 7 is arranged in the transmission frame 6, and the stepping motor 7 drives a large gear 8 for meshing transmission, and the large gear 8 drives a driving end belt tooth 9 rotates;

[0019] The two driving end belt teeth 9 are connected by a synchronous belt 10;

[0020] The executive assembly 3 includes an exposure bracket 11, and the exposure bracket 11 is displaced between the wall panels 1 through the timing belt 10. The outer wall of the exposure bracket 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com