Method for predicting steel plate thickness during rolling process

A technology of rolling process and steel plate, applied in the field of predicting the thickness of steel plate, which can solve the problems of inconvenience and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

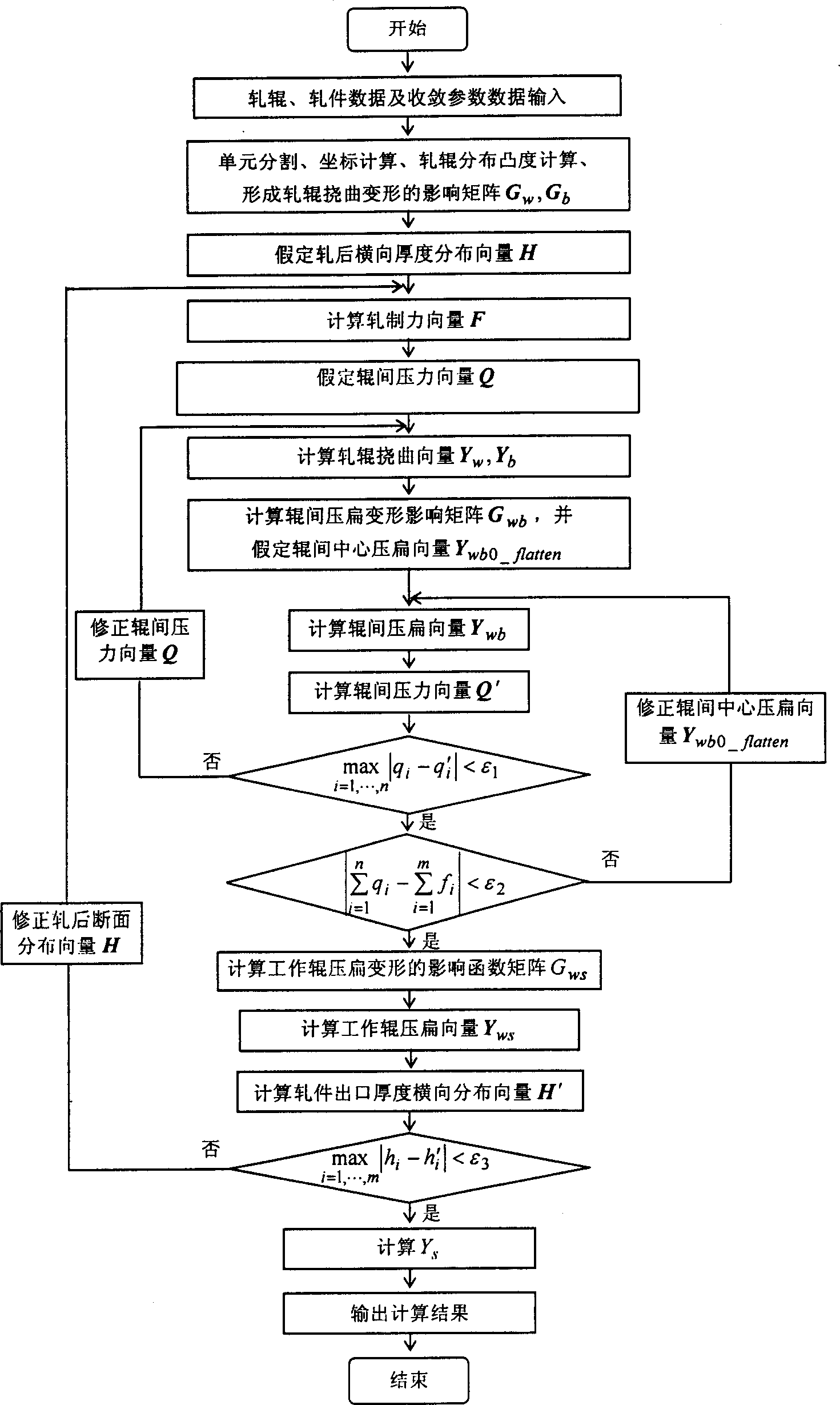

Method used

Image

Examples

Embodiment Construction

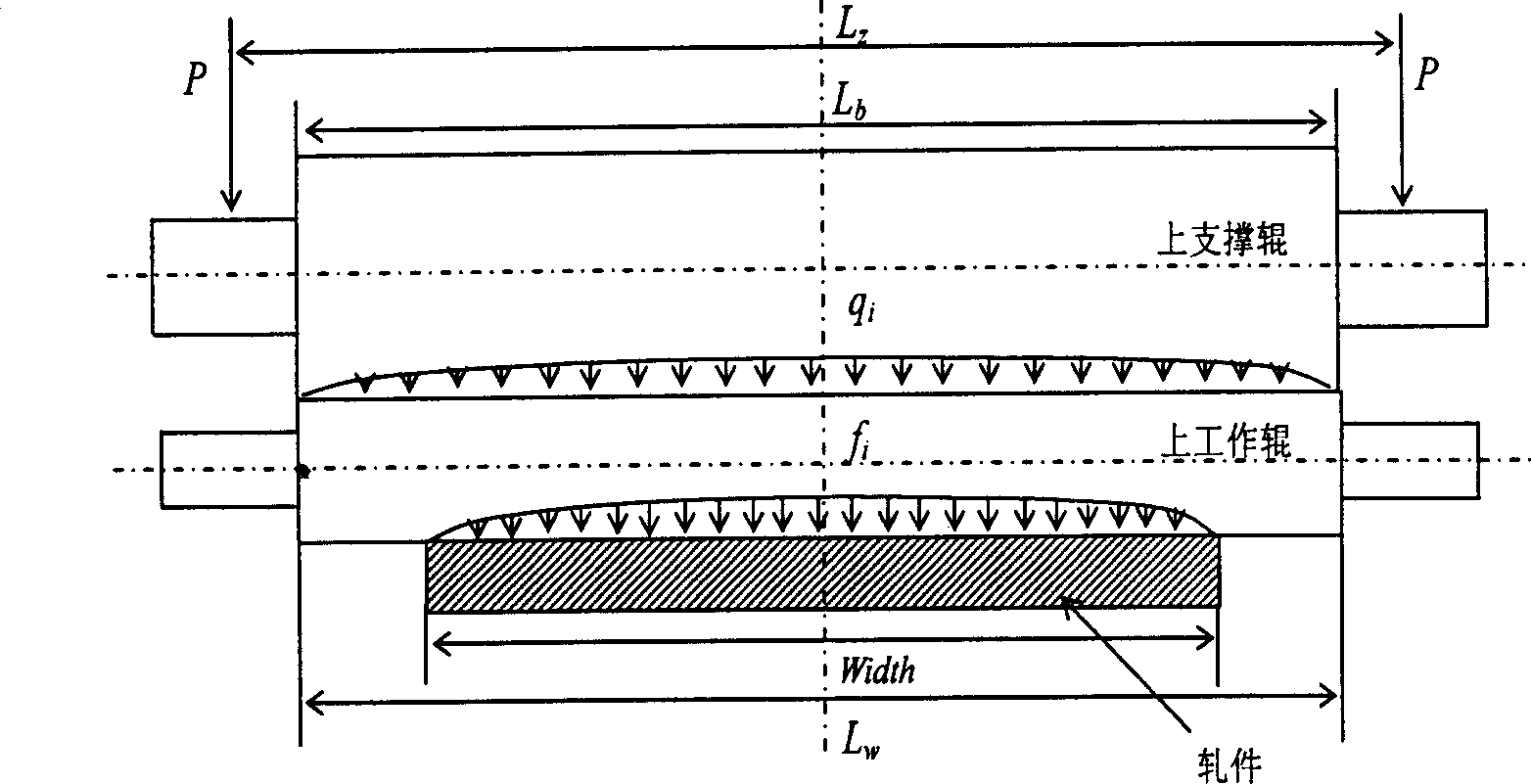

[0121] 1. Select a set of medium and heavy plate rolling mills, and use the influence function method to calculate the influence of different factors on the elastic deformation of the roll system.

[0122] Among them, Table 1 is the parameters of the plate mill.

[0123] Table 1 Calculation of initial conditions

[0124] Device name Parameter Device name Parameter

[0125] Work roll diameter / mm 900~1100 Support roll crown / um -200~200

[0126] Support roll diameter / mm 1900~2100 Roll body length / mm 3400

[0127] Work roll crown / um -300~300 Press center distance / mm 4800

[0128] Let the radii of the work rolls be equal to 450mm, 470mm, 490mm, 510mm, 530mm, and 550mm respectively; let the radii of the support rolls be equal to 950mm, 970mm, 1010mm, 1030mm, and 1050mm; ; Let the crown of the work roll be -0.3mm, -0.2mm, -0.1mm, 0mm, 0.1mm, 0.2mm respectively; let the crown of the backup roll be -0.3mm, -0.2mm, -0.1mm, 0mm, 0.1 mm, 0.2mm; this gives 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com