Method for testing grading broken stone CBR numerical value

A graded crushed stone and numerical test technology, applied in the direction of testing material hardness, etc., can solve the problems of high cost, difficulty in measuring internal material migration and stress-strain characteristics, and long design period of graded crushed stone materials, etc., to achieve Optimize composition, accurately predict effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] According to the technical solution of the present invention, this embodiment provides a CBR numerical test method for graded crushed stone, taking Ankang Yinghu limestone crushed stone as an example, the crushed stone density test results are shown in Table 1, and the micromechanical parameters are shown in Table 2.

[0067] Table 1 crushed stone density

[0068] Aggregate particle size (mm)

19~31.5

9.5~19

4.75~9.5

≤4.75

Apparent density (g / cm 3 )

2.712

2.709

2.692

2.681

[0069] Table 2 Micromechanical parameters

[0070] Poisson's ratio

Shear modulus (GPa)

0.25

8.0

0.35

[0071] Table 3 Mineral Material Grading

[0072]

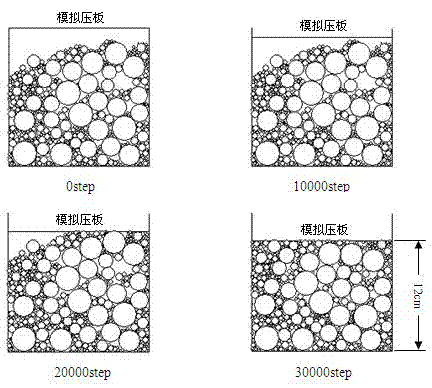

[0073] Taking the gradation A in Table 3 as an example, the implementation steps of the CBR numerical test method for graded crushed stone are as follows:

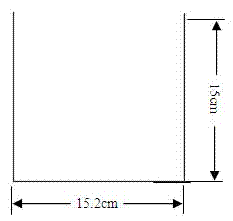

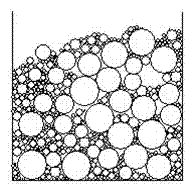

[0074] 1) Construction of physical model

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com