Carbon emission optimization method based on target cascading analytical method

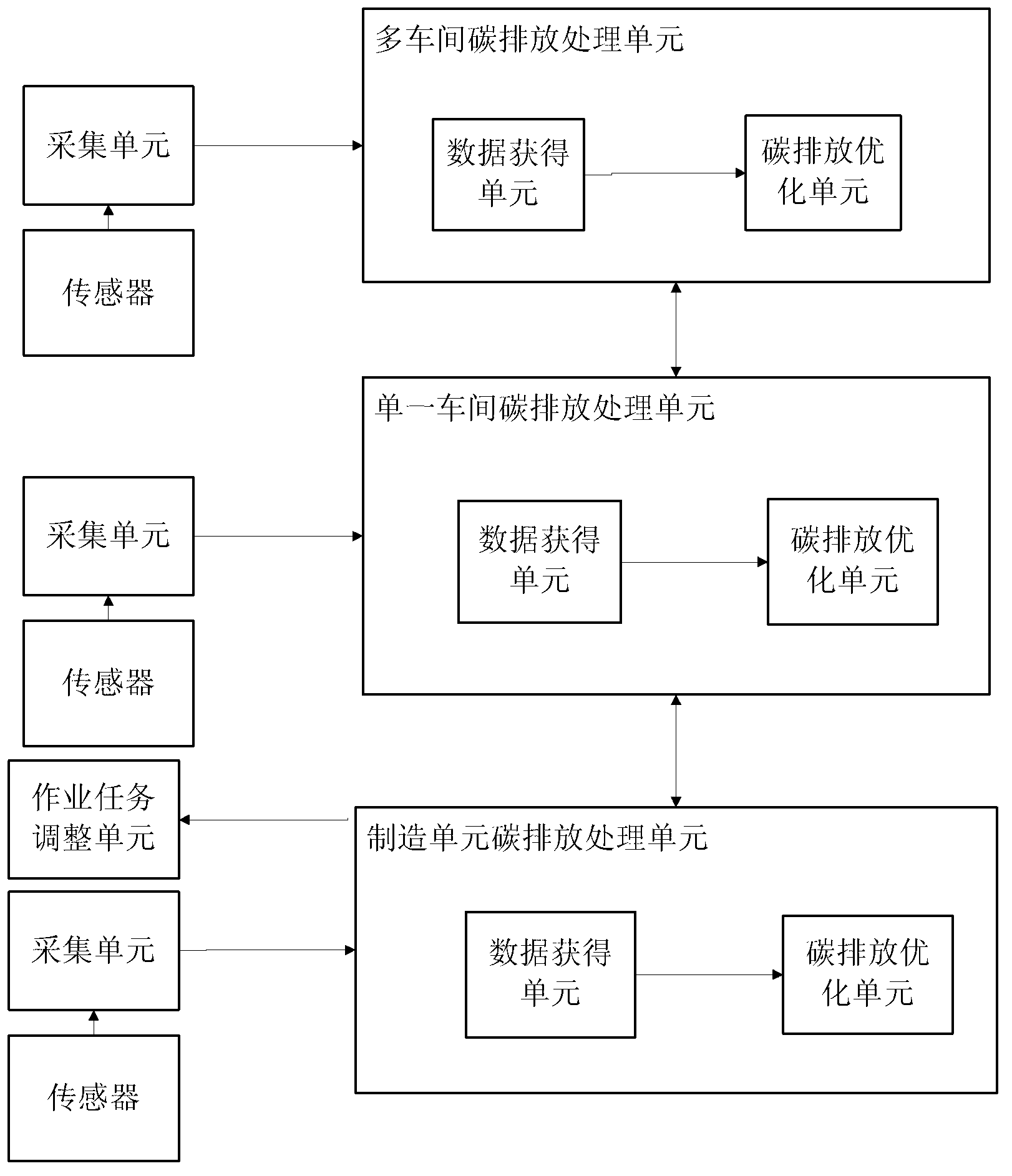

An optimization method, carbon emission technology, applied in the direction of sustainable manufacturing/processing, technology management, data processing applications, etc., can solve the problems of different scheduling models, high complexity of carbon emission process, and can not be optimized together, so as to reduce Energy cost and the effect of improving the comprehensive utilization efficiency of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

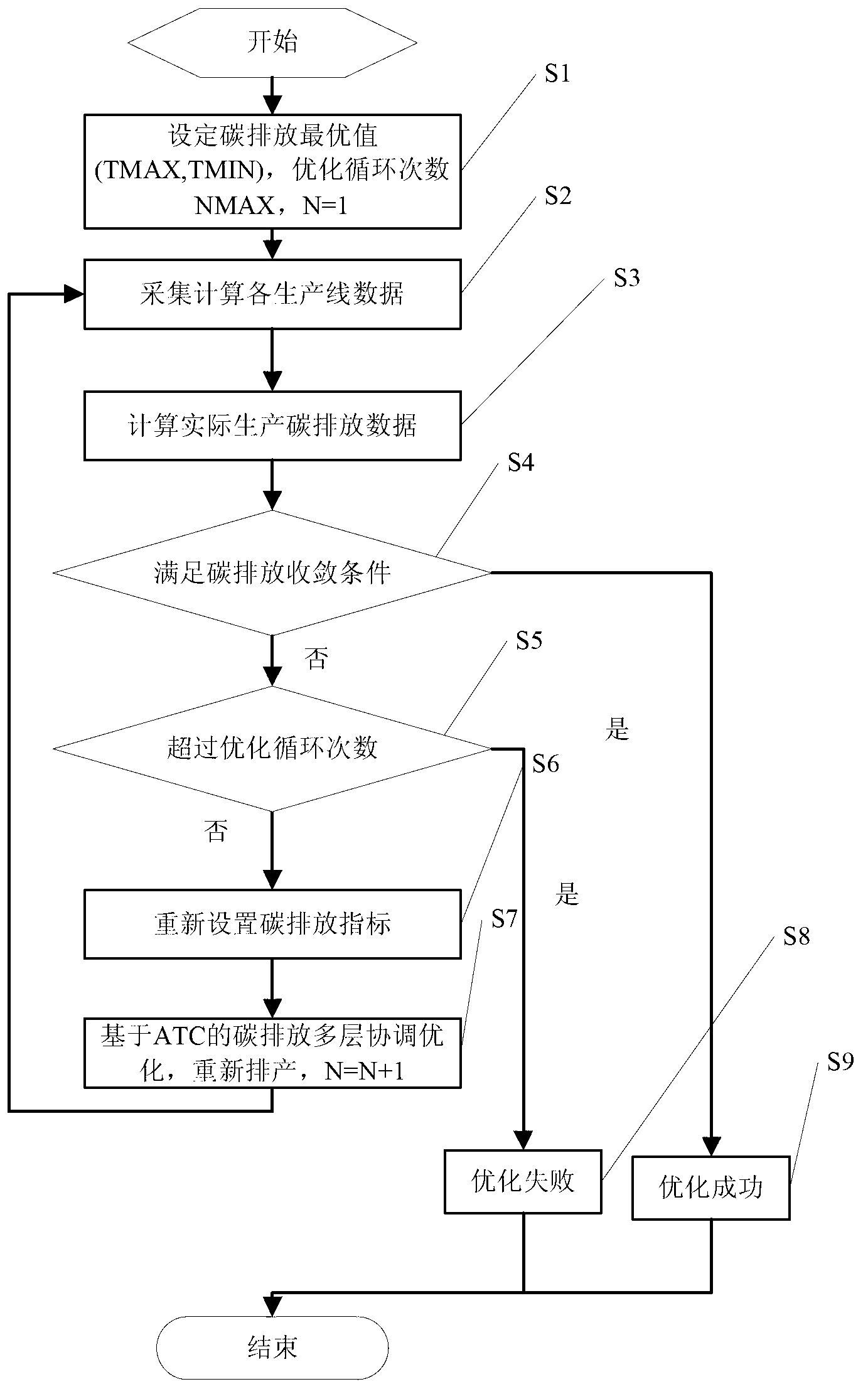

[0014] refer to figure 2 A carbon emission optimization method based on the target cascade analysis method shown, including steps:

[0015] Step S1, setting the optimal value of carbon emission TTOTAL, the maximum value of carbon emission TMAX, the minimum value of carbon emission TMIN and the limit of the number of optimization cycles NMAX, where TMIN≤TTOTAL≤TMAX;

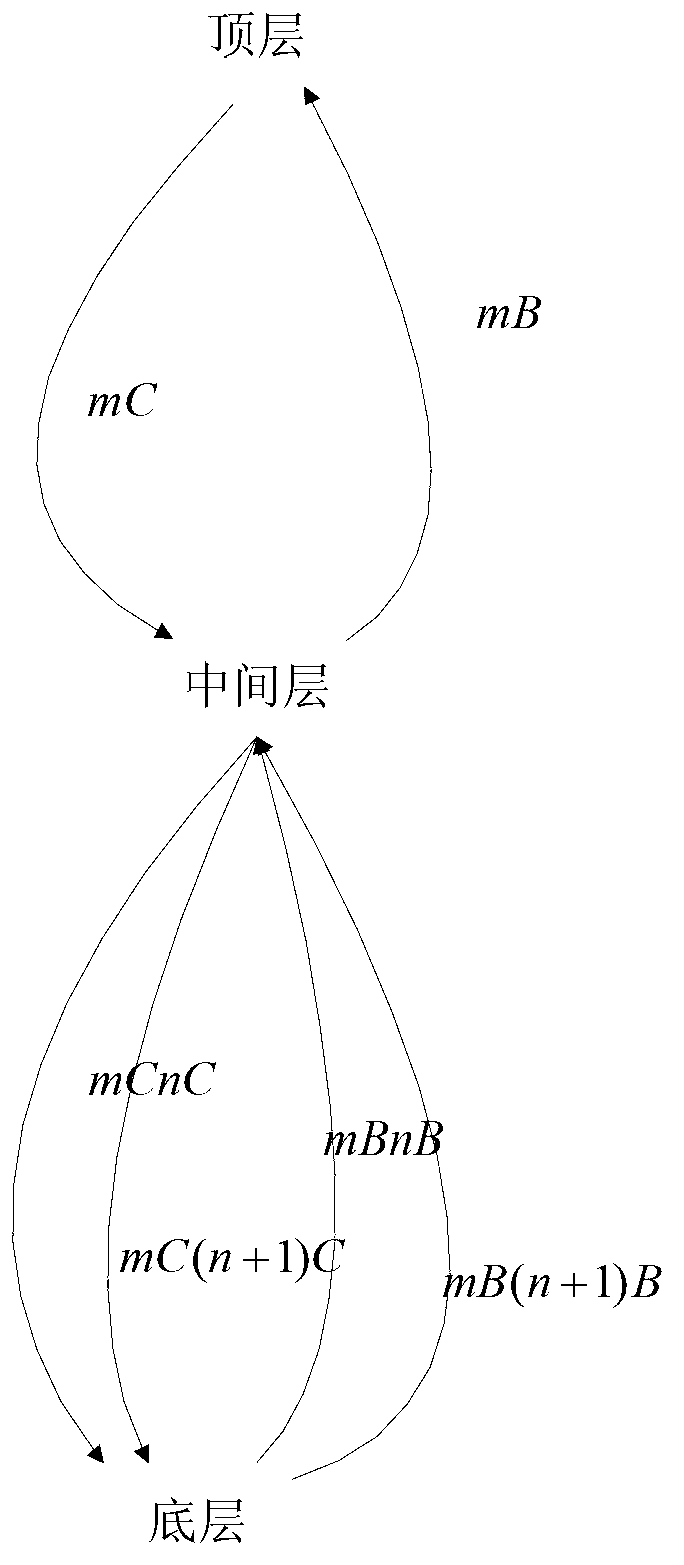

[0016] The production process is divided into the top-level multi-shop scheduling layer, the middle-level single-shop scheduling layer, and the bottom-level manufacturing unit planning layer; the manufacturing units in each manufacturing unit planning layer design their own optimal production plan by themselves.

[0017] In the distributed multi-workshop production system, the most common form is that different parts are produced in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com