Water drainage and dehydration control method of self-cleaning washing machine

A control method and washing machine technology, applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of difficulty in guaranteeing the cleaning effect of the bucket, poor cleaning intensity, and inability to eliminate the root cause of dirt, so as to prevent the growth of bacteria and prevent dirt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

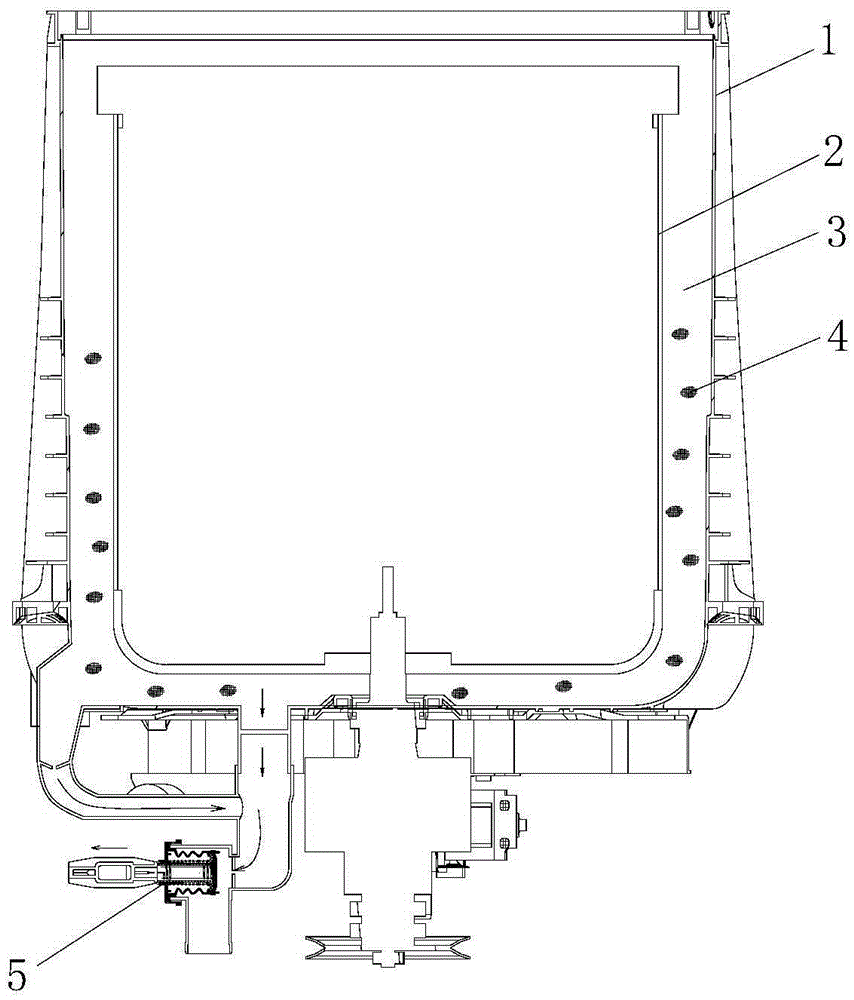

Image

Examples

Embodiment 1

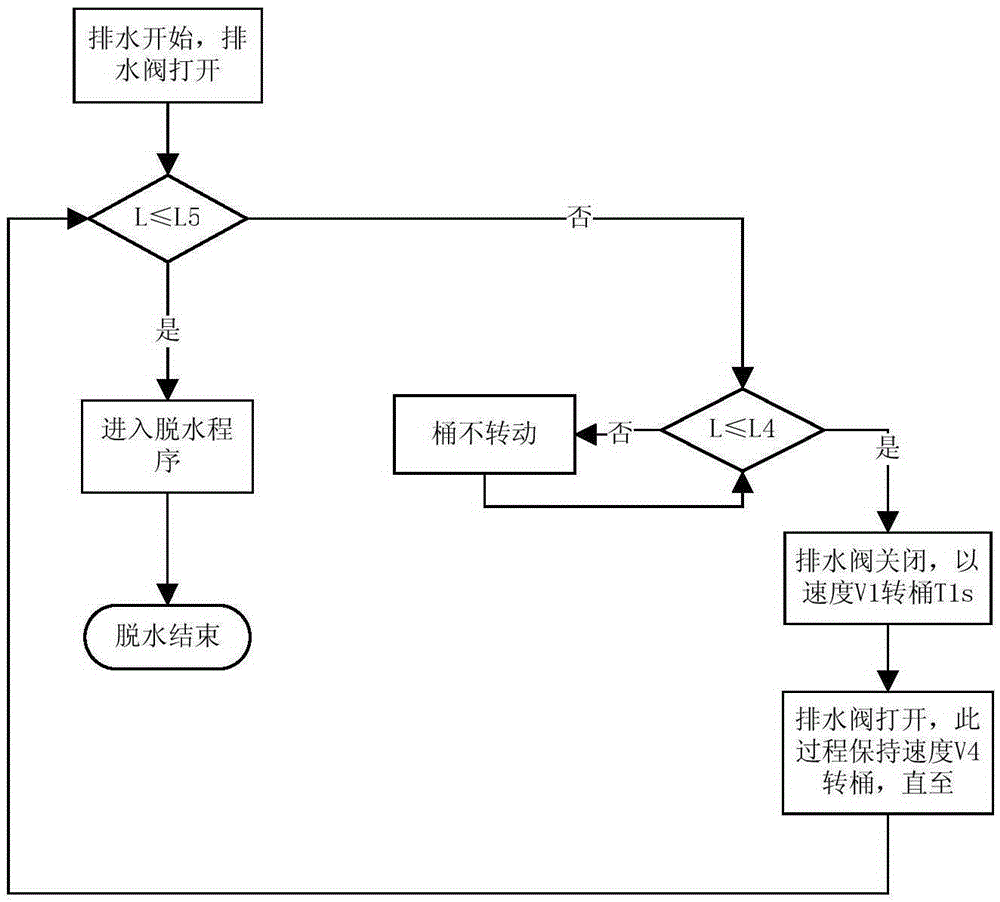

[0103] Such as figure 2 As shown, the dehydration control method of the self-cleaning washing machine in this embodiment:

[0104] (1) Drainage begins, open the drain valve, and enter the next step;

[0105] (2) Detect water level L, judge whether L≤L5, if so, then enter step (6), if not, then enter next step;

[0106] (3) Determine whether L≤L4, L4

[0107] (4) Close the drain valve, control the inner barrel to rotate at a speed of V1=200RPM for 2S, and enter the next step;

[0108] (5) Open the drain valve, control the inner barrel to rotate at a speed of V4=20RPM until L≤L5, and enter the next step;

[0109] (6) Execute the dehydration program until the end of dehydration.

[0110] L5 corresponds to the empty bucket point judged by the water level sensor of the washing machine. If the water level reaches L5, it will immediately enter the dehydration program. When there is a lot of water...

Embodiment 2

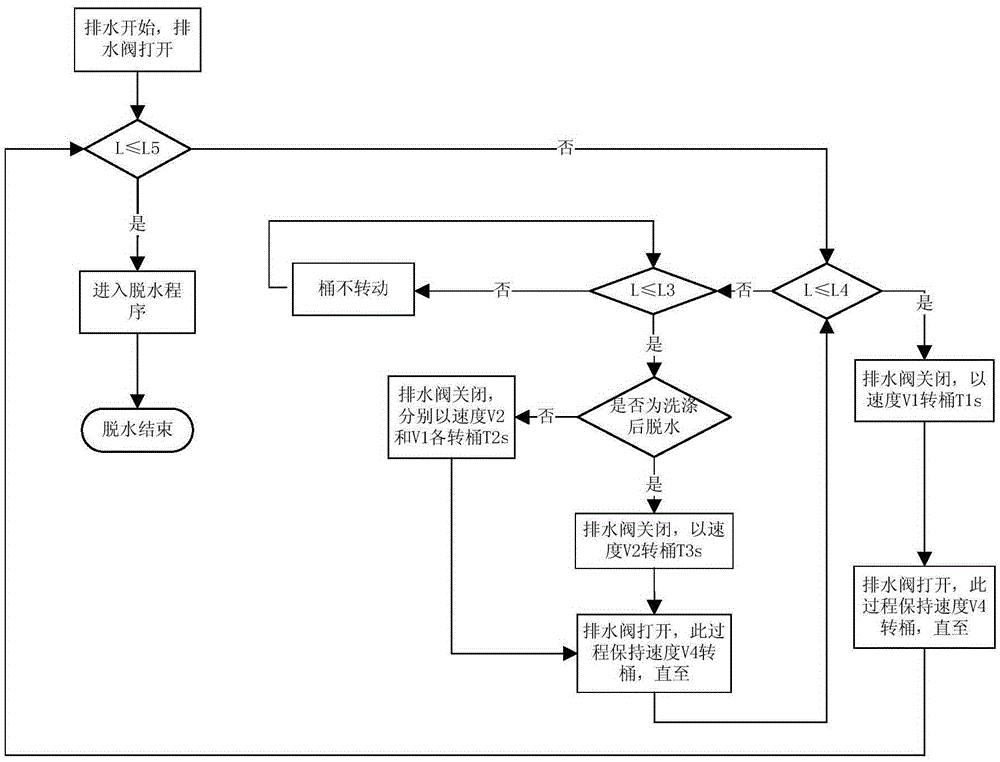

[0112] Such as image 3 As shown, the self-cleaning washing machine drainage and dehydration control method in this embodiment:

[0113] (1) Drainage begins, open the drain valve, and enter the next step;

[0114] (2) Detect the water level L, judge whether L≤L5, if so, then enter step (9), if not, then enter the next step;

[0115] (3) judge whether L≤L4, if so, then enter the next step, if not, then enter step (6);

[0116] (4) Close the drain valve, control the inner barrel to rotate at a speed of V1=160RPM for 3S, and enter the next step;

[0117] (5) Open the drain valve, control the inner barrel to rotate at a speed of V4=30RPM until L≤L5, and enter step (9);

[0118] (6) Determine whether L≤L3, if so, enter the next step, if not, drain water until L≤L3, and enter the next step;

[0119] (7) Determine whether it is dehydration after washing, if so, close the drain valve, control the inner barrel to rotate at a speed of V2=100RPM for 4S, and enter the next step, if no...

Embodiment 3

[0123] Such as Figure 4 As shown, the self-cleaning washing machine drainage and dehydration control method in this embodiment:

[0124] (1) Drainage begins, open the drain valve, and enter the next step;

[0125] (2) Detect water level L, judge whether L≤L5, if so, then enter step (11), if not, then enter next step;

[0126] (3) judge whether L≤L4, if so, then enter the next step, if not, then enter step (6);

[0127] (4) Close the drain valve, control the inner bucket to rotate for 2S at the speed V1=150RPM, and enter the next step;

[0128] (5) Open the drain valve, control the inner bucket to rotate with the rotating speed V4=20RPM, until L≤L5, enter step (11);

[0129] (6) judge whether L≤L3, if so, then enter the next step, if not, then enter step (9);

[0130] (7) Determine whether it is dehydration after washing, if so, close the drain valve, control the inner barrel to rotate at a speed of V2=80RPM for 5 seconds, and enter the next step, if not, close the drain v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com