Efficient flowback method of pulverized coal for coal-bed gas well

A technology for coalbed methane wells and pulverized coal is applied in the field of high-efficiency flowback of pulverized coal from coalbed methane wells, and can solve the problems of stuck pump, poor gas production effect, low pump efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

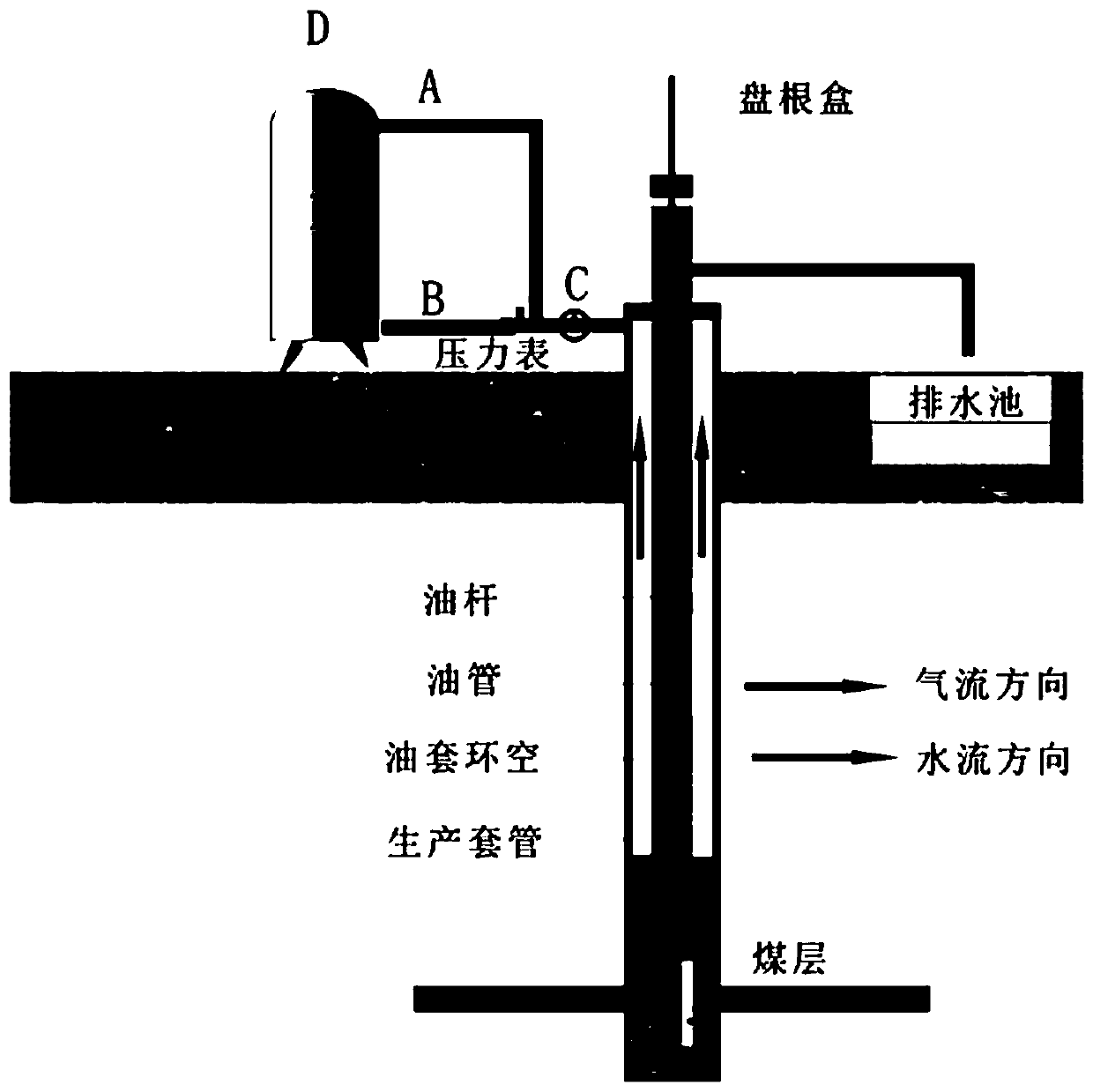

[0019] According to the characteristics of coal powder, the invention prepares a chemical cleaning agent with high foam quality and strong coal powder carrying capacity; invents a simple and safe injection device; formulates safe injection measures and post-injection drainage management methods. There is no need for an external high-pressure pump when the chemical cleaning agent is injected, and it is connected through a pipeline to balance the pressure of the tank body and the annular space of the oil jacket, and then flow into the annular space of the oil jacket by its own gravity. And judge whether the foam will enter the gathering and transportation pipeline according to the gas production of the gas well, and then determine the opening degree of the intake valve.

[0020] In conjunction with the accompanying drawings, the specific implementation steps of the present invention are further described:

[0021] Such as figure 1 As shown, before injection, stop the pumping un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com