Straight line driving reciprocating rotation screw pump

A reciprocating rotation and linear drive technology, applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of increased investment costs, scrapping of pumping units, waste of resources, etc., to achieve resource saving, wide application range, work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

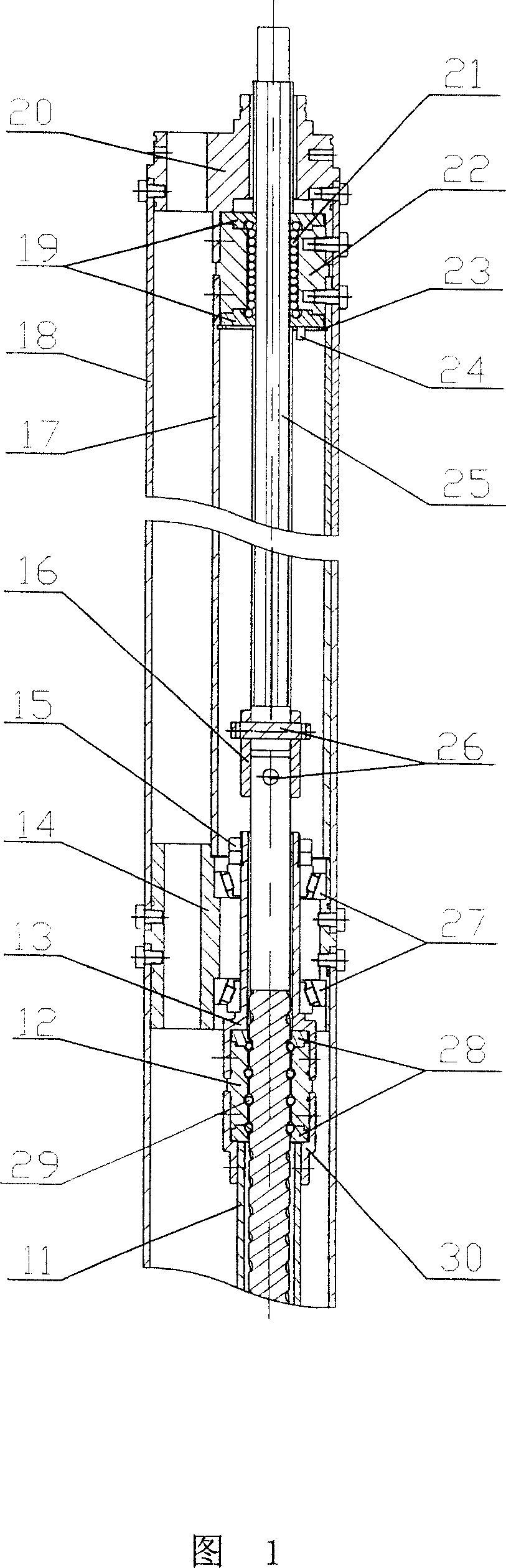

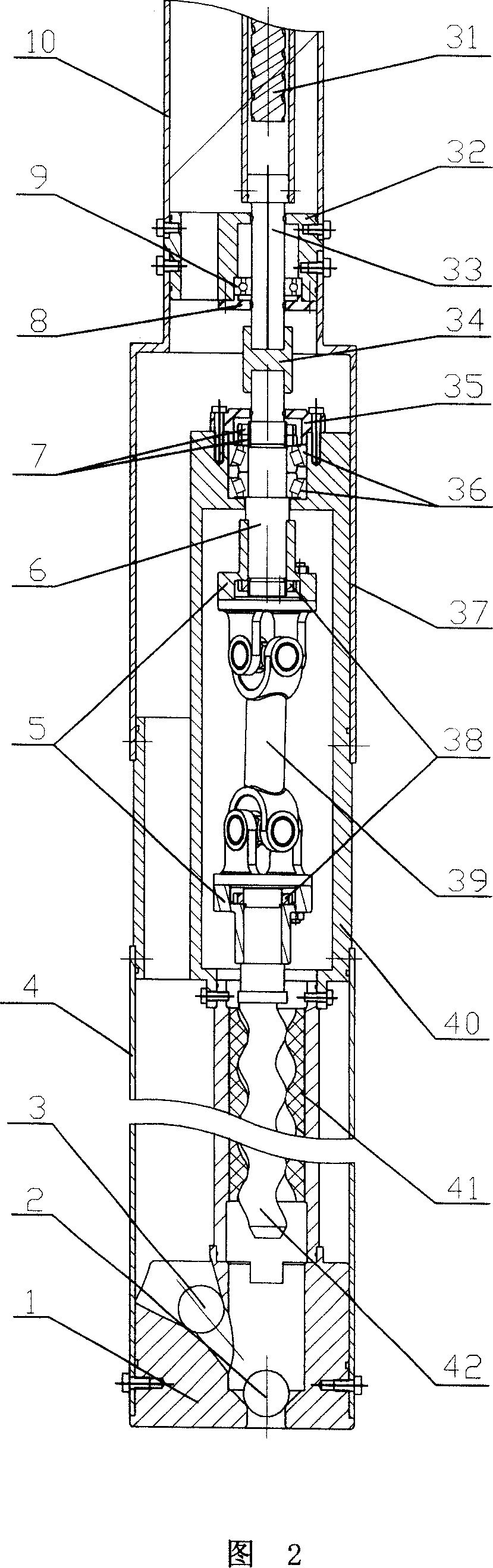

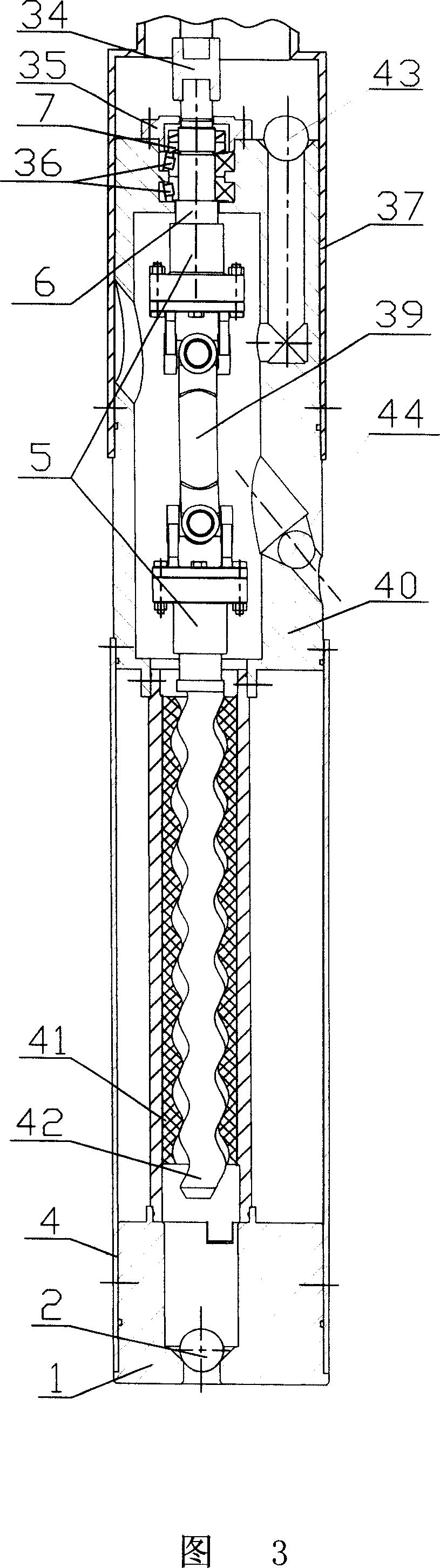

[0009] As shown in the figure, the present invention mainly consists of a pump base 1, an oil inlet valve (1) 2, an oil outlet valve (2) 3, a pump casing connecting sleeve 4, a connecting flange 5, a connecting shaft (1) 6, and a lock nut 7. Bearing end cover 8, radial ball bearing 9, connection sleeve (two) 10, transmission sleeve (one) 11, straight rotation sleeve 12, support shaft sleeve 13, middle joint 14, lock nut 15, connection sleeve (three) ) 16, spacer sleeve 17, connecting sleeve (four) 18, ball return block 19, upper joint 20, spline ball 21, spline sleeve 22, elastic retaining ring 23, positioning pin 24, spline shaft 25, pin shaft 26 , tapered roller bearing 27, straight-rotating ball block 28, ball 29, transmission sleeve (2) 30, straight-rotating screw shaft 31, bottom joint 32, connecting shaft (2) 33, connecting sleeve (1) 34, bearing end Cover 35, tapered roller bearing 36, variable section connecting sleeve 37, fastening nut 38, universal coupling 39, pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com