Straight-line parallel flow water injection oil extraction method

A parallel flow and straight line technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of waste of oil resources, low recovery rate of oil water injection, etc., to reduce water blocking and improve development economy benefit, and the effect of improving water flooding sweep coefficient

Inactive Publication Date: 2008-10-22

YANGTZE UNIVERSITY

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

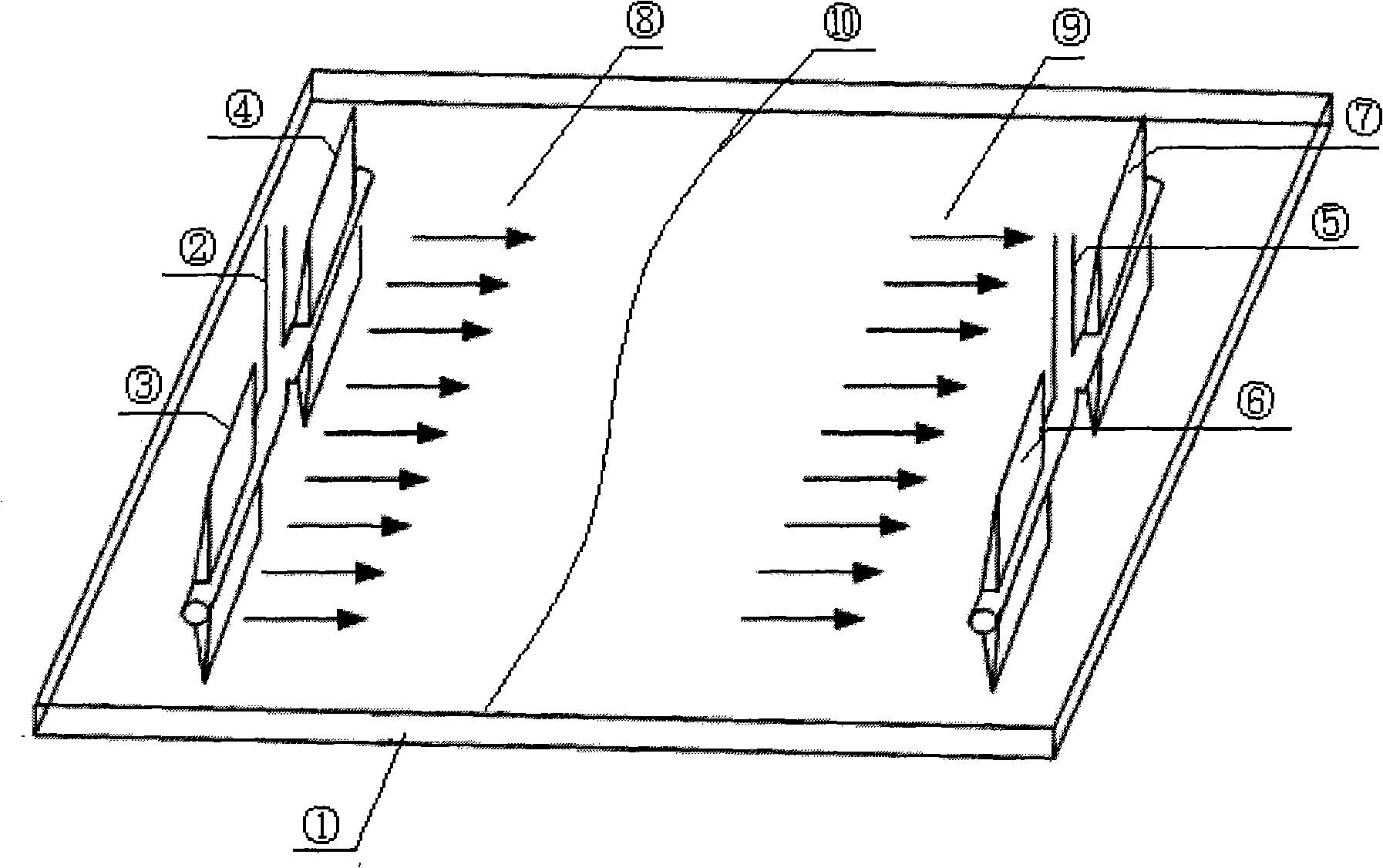

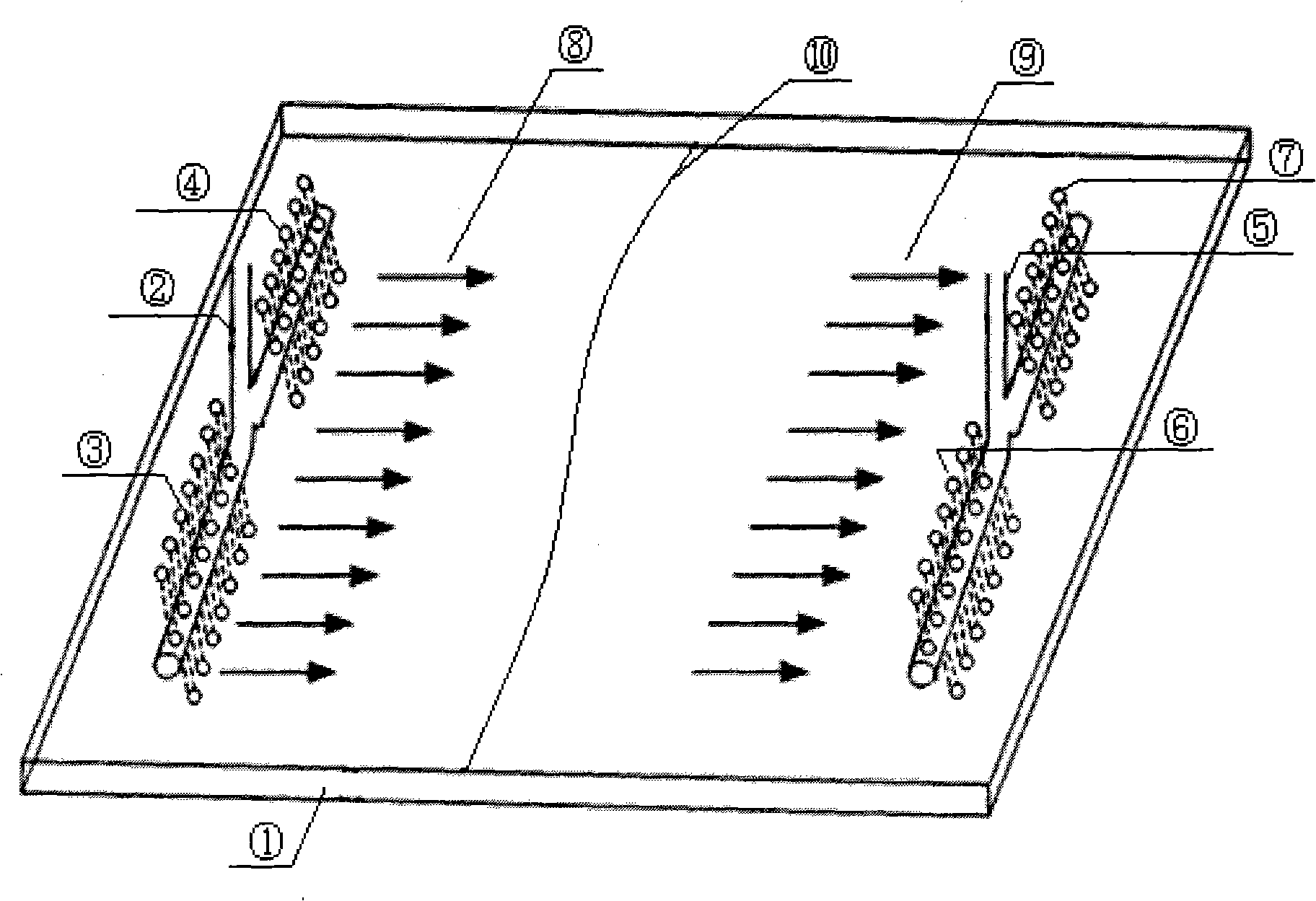

The invention relates to a linear parallel-flow water-injection oil excavating method, belonging to the gas field excavating method technical field. The method is characterized in that a plurality of horizontal production wells and a plurality of horizontal water-injection wells are obtained by drilling an oil layer which is suitable for injecting water and excavating with the horizontal wells; the production wells and the water-injection wells are respectively arranged at a certain interval in a row; an injecting well drainage and a production well drainage are alternately arranged and are parallel with each other; the water-injection well and the production well are either single pitshaft horizontal wells or horizontal branch wells; two branches of each horizontal branch well have certain horizontal section lengths and have opposite directions in the same vertical plane; and the horizontal section of each horizontal well is perforated from up to down and is fractured so as to generate an eyelet or a crack, the crude excavation is carried out through injecting water from the water-injection well to the oil layer. The linear parallel-flow water-injection oil excavating method is applied, the fingering phenomenon of the injected water can be improved, the utilization rate of the injected water is improved, the production of residual oil is reduced, recovery percent of the water-injection oil excavating for oil is improved, the waste of oil resource is reduced, and economic benefits for oil-field development is improved greatly.

Description

Straight-line Parallel Flow Water Injection Oil Recovery Method Technical field: The invention relates to a linear parallel flow water injection oil production method, which belongs to the technical field of oil and gas field production method design. Background technique: At present, oil water injection production usually adopts the radial flow production method. Regardless of whether it is a vertical well or a horizontal well, for the production well, the fluid flows into the wellbore in a radial seepage manner within a certain range near the wellbore. For water injection wells, the wellbore is the center, and the injected fluid flows to the surroundings in a radial flow manner. More than two-thirds of my country's crude oil extraction is exploited by artificial water injection, and all of them adopt vertical well water injection for vertical well oil production or vertical well water injection for horizontal well oil production. Artificial water injection development ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B43/20

Inventor 周克厚马兵

Owner YANGTZE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com