Method of integral throughput in multiple wells for extracting thick oil

An overall, heavy oil technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low vapor pressure energy and thermal energy utilization, interwell interference, unfavorable huff and puff production life, etc., and achieve prolongation The effects of throughput life, prolonging life, and expanding the range of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

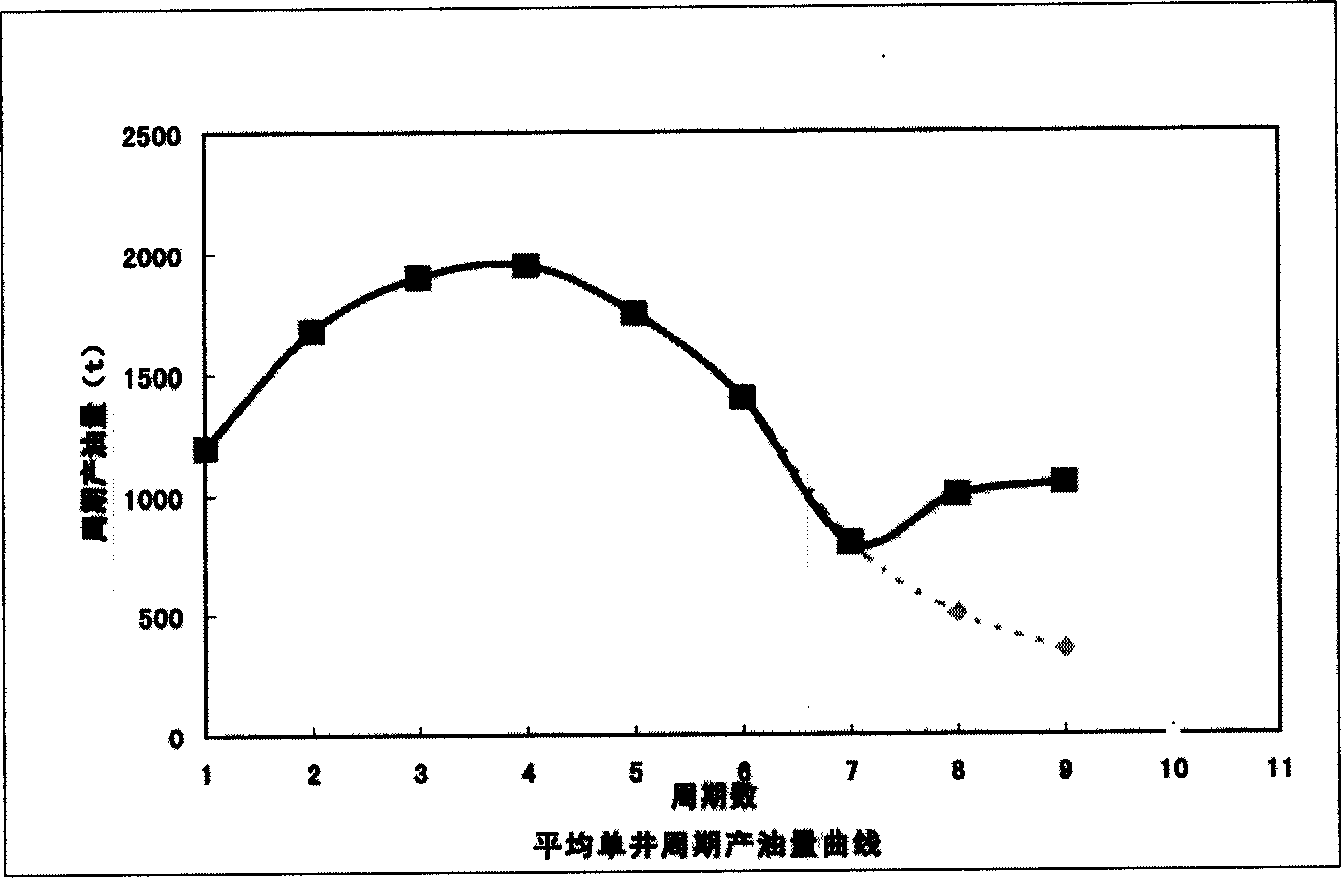

Embodiment 1

[0033] The buried depth of oilfield 1 is 300-600m, the effective thickness of oil layer is 35.0m, the ratio of net to total thickness is 0.6, the average porosity is 30%, the average permeability is 1000md, the coefficient of variation of permeability is 0.7, and the viscosity of crude oil under oil layer conditions is 10 ×10 4 cp, the original oil saturation is 70%. The oil field has been developed by single well steam stimulation, and the steam channeling is serious, the single well production drops rapidly, and the recovery degree is low.

[0034] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.40, total reservoir thickness > 5.0m, net-to-total thickness ratio > 0.4, reservoir porosity > 0.15, permeability variation coefficient < 0.8;

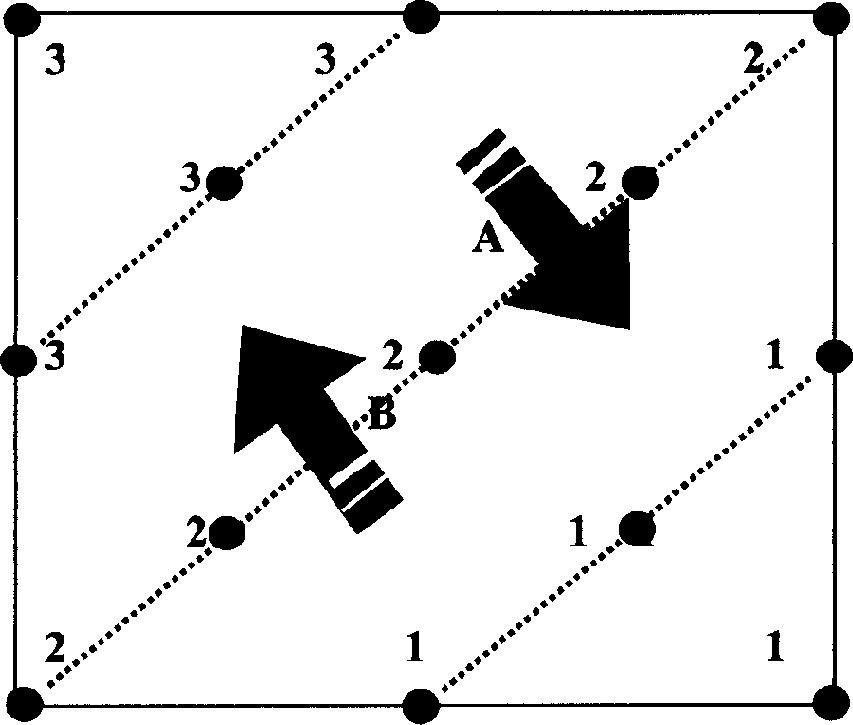

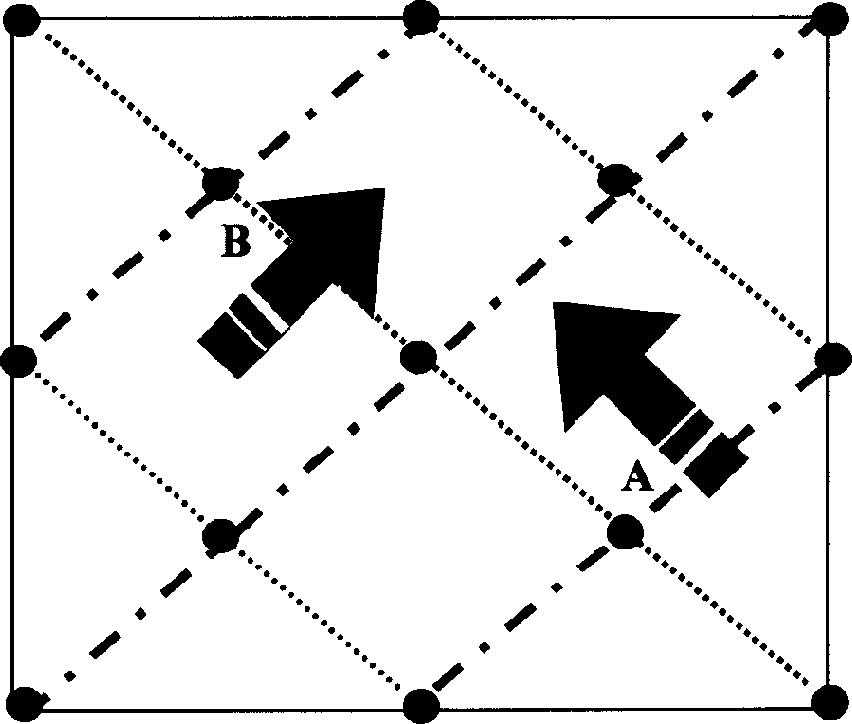

[0035] 2) Using the existing well pattern with a row spacing of 167m and a well spacing of 98m, according to ...

Embodiment 2

[0039] The buried depth of oil field 2 is 500-800m, the effective thickness of the oil layer is 30.0m, the net total thickness ratio is 0.5, the average porosity is 35%, the average permeability is 1500md, the coefficient of variation of permeability is 0.7, and the crude oil gravity under the oil layer conditions is 13API , the original oil saturation is 60%. The oil field has been developed by single well steam stimulation, and the steam channeling is serious, the single well production drops rapidly, and the recovery degree is low.

[0040] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.40, total reservoir thickness > 5.0m, net-to-total thickness ratio > 0.4, reservoir porosity > 0.15, permeability variation coefficient < 0.8;

[0041] 2) Using the existing well pattern with a well spacing of 70m, according to the capacity of steam injection eq...

Embodiment 3

[0045] The buried depth of the oil reservoir in Oilfield 3 is 830-1060m, the effective thickness of the oil layer is 41.0m, the net total thickness ratio is 0.5, the average porosity is 26%, the average permeability is 1062md, the permeability variation coefficient is 0.7, and the crude oil is degassed at 50°C The viscosity is 16.80×10 4 cp, the original oil saturation is 65%. The oil field has been developed by single well steam huff and puff, and the steam channeling is serious, with a steam channeling rate of more than 50%, and the single well production drops rapidly, and the recovery degree is only 10%.

[0046] 1) Carry out rough screening according to the geological characteristics and development status of the oilfield. The reservoir meets the following conditions: reservoir depth 0.40, total reservoir thickness > 5.0m, net-to-total thickness ratio > 0.4, reservoir porosity > 0.15, permeability variation coefficient < 0.8;

[0047] 2) Using the existing well pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Effective thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com