Environmentally-friendly composite rust mud stripping agent and preparation method thereof

A compound type and stripping agent technology, which is applied in the cleaning field of industrial circulating water system, can solve the problems of water and electricity resource loss, production and operation loss, pollution, etc., and achieve the effect of short cleaning time, good stripping effect and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

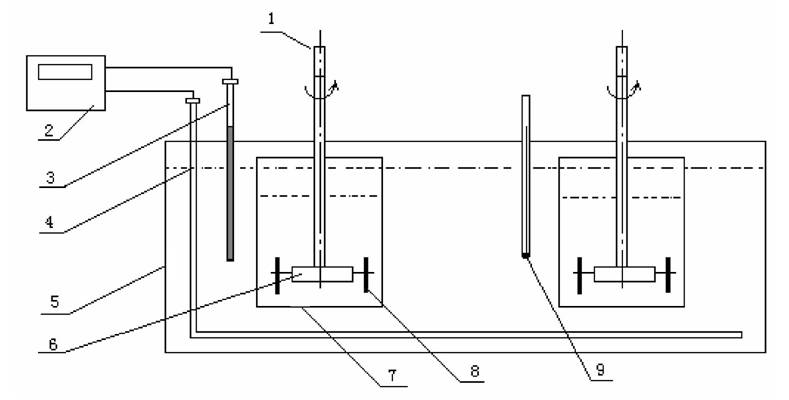

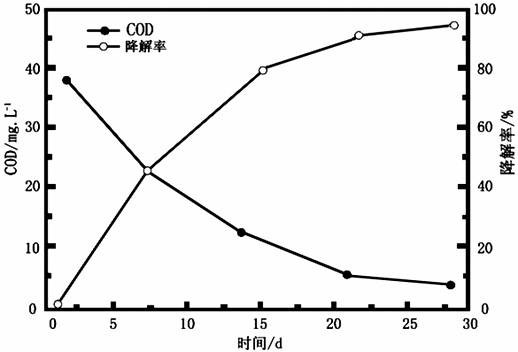

Method used

Image

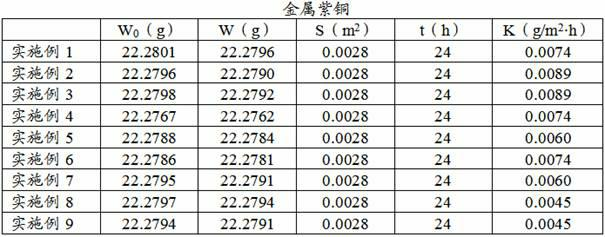

Examples

Embodiment 1

[0034] 100kg of environmentally friendly composite rust and mud stripper consists of the following components by weight: 5kg of tetradecyldimethylbenzyl ammonium bromide, 2kg of sodium polyacrylate, and the balance is water.

[0035] The preparation steps are as follows:

[0036] 1) In the preparation container, add tetradecyl dimethyl benzyl ammonium bromide and sodium polyacrylate in sequence while stirring at room temperature, and continue stirring for 8 minutes until uniform;

[0037] 2) Add water to 1) to make up to 100kg, stir for 15 minutes until uniform, cool to room temperature, and the finished product is prepared.

Embodiment 2

[0039] 100kg of environmentally friendly composite rust and mud stripper consists of the following components by weight: 6kg of tetradecyl dimethyl benzyl ammonium bromide, 3 kg of sodium polyacrylate, and the balance is water.

[0040] The preparation steps are as follows:

[0041] 1) In the preparation container, add tetradecyl dimethyl benzyl ammonium bromide and sodium polyacrylate in sequence while stirring at room temperature, and continue stirring for 9 minutes until uniform;

[0042] 2) Add water to 1) to make up to 100kg, stir for 18 minutes until uniform, cool to room temperature, and the finished product is prepared.

Embodiment 3

[0044] 100kg of environmentally friendly composite rust and mud stripper consists of the following components by weight: 8kg of tetradecyl dimethyl benzyl ammonium bromide, 5 kg of sodium polyacrylate, and the balance is water.

[0045] The preparation steps are as follows:

[0046] 1) In the preparation container, add tetradecyl dimethyl benzyl ammonium bromide and sodium polyacrylate in sequence while stirring at room temperature, and continue stirring for 10 minutes until uniform;

[0047] 2) Add water to 1) to make up to 100kg, stir for 20 minutes until uniform, cool to room temperature, and the finished product is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com