Method for preparing bidirectional thermal-adjustable fabric with phase change polyurethane heat-sensitive material microcapsule

A heat-sensitive material and microcapsule technology, applied in the field of fabrics, can solve the problems of high production difficulty, high weaving end breakage rate and low yarn strength, and achieve the effect of less production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

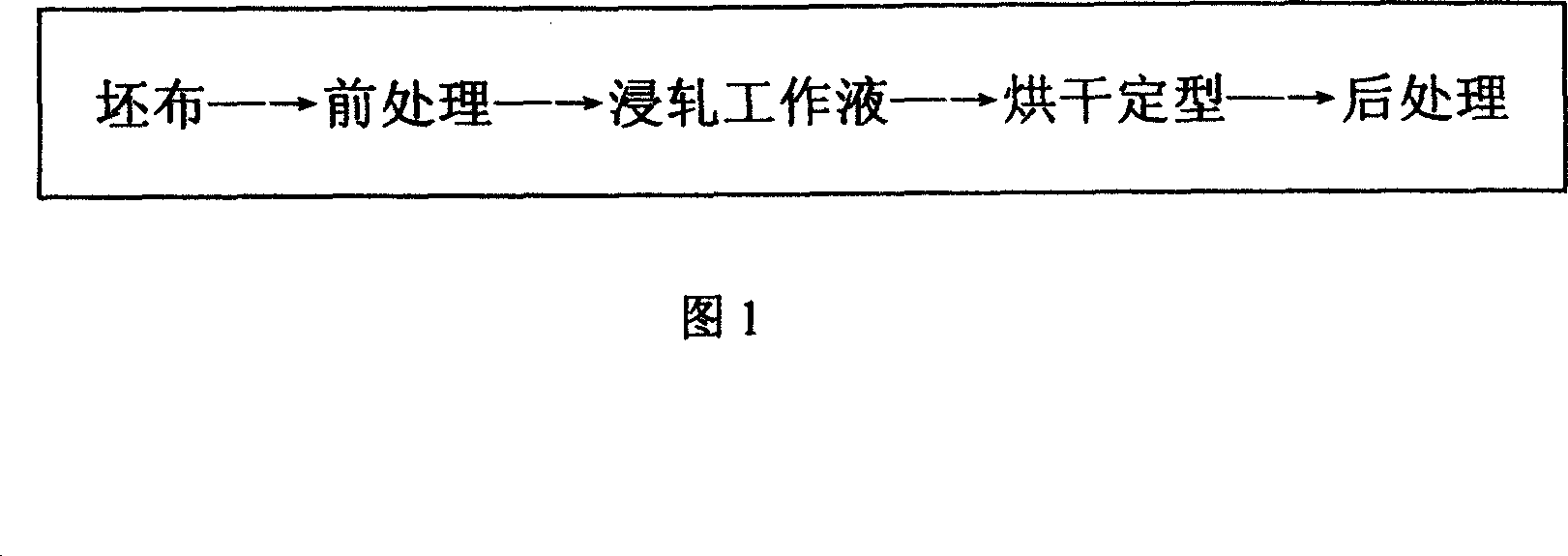

Method used

Image

Examples

Embodiment 1

[0028] Release 8kg of polyurethane-wrapped heat-sensitive material microcapsules of n-eicosane as the heat-sensitive phase change material, 4kg of polyacrylate, and 3kg of softener in the chemical tank to 100L, stir them evenly, and put them into the rolling groove of the setting machine Inside, the pre-treated cloth is dipped through the rolling groove, and the pressure of the roll is 2.5kg / cm 2 , and then baked in a drying room at 110°C for 45 seconds, and then subjected to post-shrinkage treatment to obtain a phase-change polyurethane heat-sensitive material microcapsule two-way temperature-regulating fabric with a phase change temperature of 36.4°C.

Embodiment 2

[0030] The heat-sensitive phase-change material in embodiment 1 is changed to the mixture of n-octadecane 33% (weight percent), n-docosane 67% (weight percent), and all the other ways are unchanged, so that the phase transition temperature is 37.8 ℃ phase-change polyurethane heat-sensitive material microcapsule two-way temperature-regulating fabric.

Embodiment 3

[0032] The heat-sensitive phase-change material in embodiment 1 is changed to the mixture of n-hexadecane 25% (weight percent), n-docosane 75% (weight percent), and all the other ways are unchanged, so that the phase transition temperature is 37 ℃ phase-change polyurethane heat-sensitive material microcapsule two-way temperature-regulating fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com