Multifunctional viscose with functions such as temperature regulation and bacterium resistance, preparation method of viscose and fabric

A viscose fiber and multi-functional technology, applied in the direction of artificial filaments made of viscose, can solve the problems of antibacterial or single temperature control, achieve the effect of lasting coolness, protection of human health, and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing viscose fibers with multiple functions such as temperature control and antibacterial, comprising the following steps:

[0040] mixing the phase-change microcapsule emulsion, the graphene dispersion and the viscose solution to obtain a spinning solution; the phase-change microcapsules include a polymer capsule wall and a phase-change material embedded in the polymer capsule wall; the The phase change material is selected from n-tetradecane, n-pentadecane, n-hexadecane, n-heptadecane, n-octadecane, n-nonadecane, n-eicosane and polyethylene glycol E600 or more;

[0041] The spinning liquid enters the coagulation bath through the spinneret, and the as-spun fibers are separated out, and then the multifunctional viscose fibers are obtained through drafting and winding.

[0042] The viscose fiber prepared by the invention has multiple functions such as temperature control and antibacterial, and can be used as clothing fabrics to k...

Embodiment 1

[0061] a) Phase change microcapsule emulsion preparation:

[0062] Mix 20g of styrene, 2g of butyl acrylate, 0.1g of methyl methacrylate, and 25g of n-octadecane evenly, pour 0.3g of isotridecyl alcohol polyoxyethylene ether containing emulsifier 7, dodecylbenzene In an aqueous solution of 0.15 g of sodium sulfonate and 0.05 g of sodium lauryl sulfate, including 30 parts of water, pre-emulsify for 60 minutes. The resulting pre-emulsion is placed in a reaction kettle, heated to 70°C, and an initiator potassium persulfate aqueous solution (0.08g potassium persulfate is dissolved in 6g deionized water) is added, and the reaction ends after 4.5h to obtain phase-change microcapsules containing lotion.

[0063] b) prepare graphene dispersion:

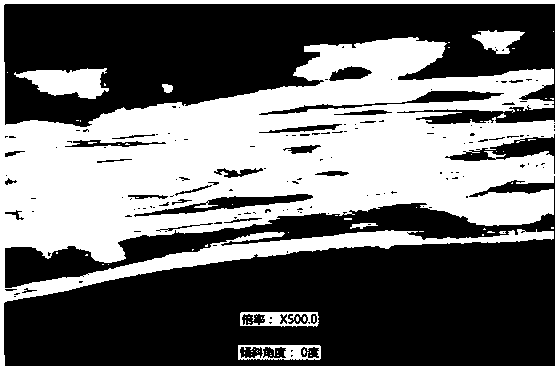

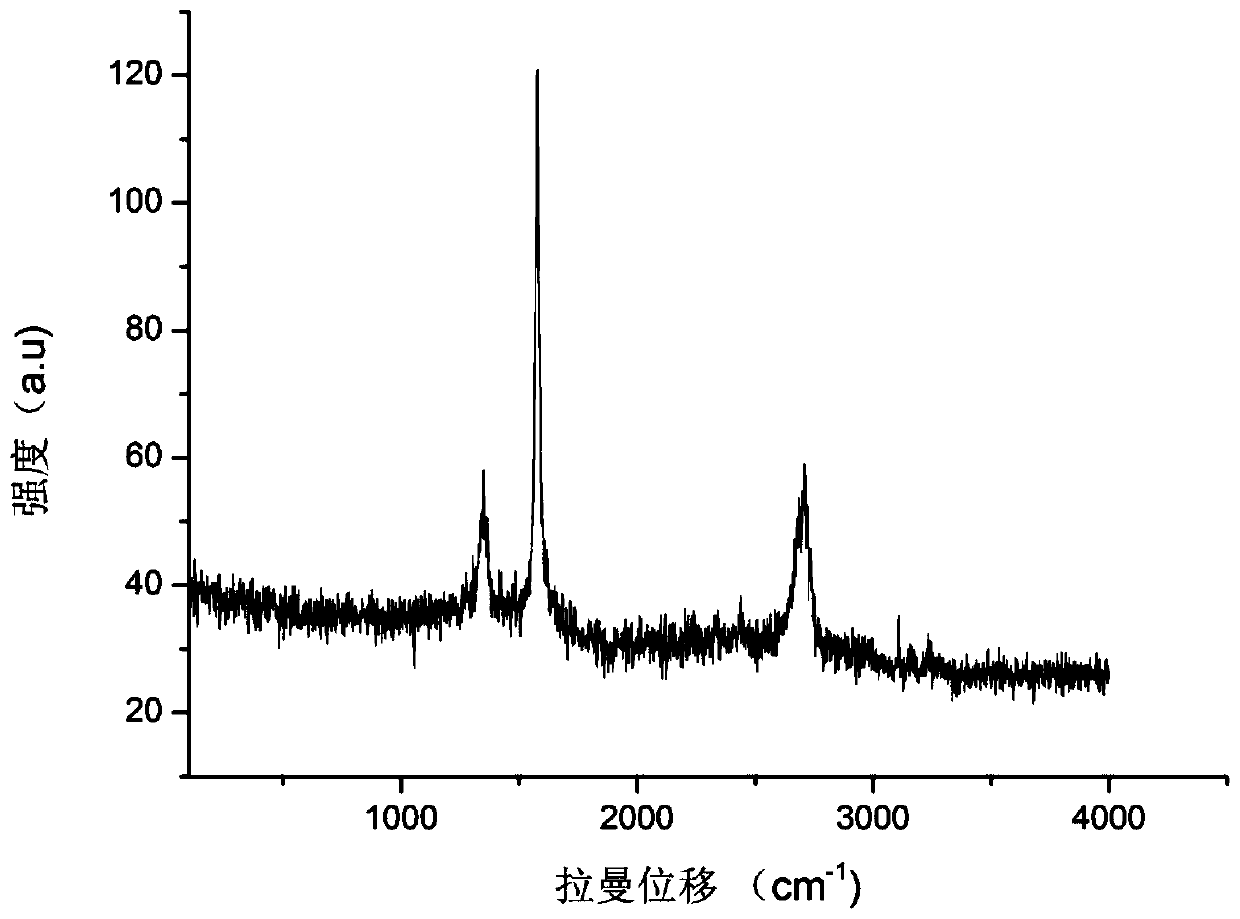

[0064] Get 6 parts of graphene powders prepared by physical exfoliation method, 0.3 part of dispersant Tween 20, 0.3 part of Tween 60, 0.3 part of sodium dodecylbenzene sulfonate and sodium α-olefin sulfonate (RCH=CH(CH 2 ) n -SO 3 Na, R...

Embodiment 2

[0078] a) Phase change microcapsule emulsion preparation:

[0079] Mix 22g of styrene, 4g of butyl acrylate, 1.5g of methyl methacrylate, 0.5g of acrylonitrile, and 30g of phase change material, and pour 0.3 parts of isotridecyl alcohol polyoxyethylene ether containing emulsifier 9, iso 70.05 parts of tridecyl polyoxyethylene ether, 0.1 part of sodium dodecylbenzenesulfonate, and 0.1 part of sodium dihexyl succinate sulfonate in an aqueous solution, including 40 parts of water, and pre-emulsified for 60 minutes. The obtained pre-emulsion was placed in a reaction kettle, and the temperature was raised to 70° C., an aqueous initiator potassium persulfate solution (0.09 g potassium persulfate dissolved in 10 g deionized water) was added, and the reaction was completed after 5 hours to obtain an emulsion containing phase-change microcapsules .

[0080] Among them, the phase change material is a mixture of n-tetradecane, n-pentadecane and n-eicosane, and the mass ratio is 1:3:6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com