Non-ionic composition used for removing keratin and preparation method of non-ionic composition

A non-ionic, exfoliating technology, applied in the field of daily chemicals, can solve the problem of limited exfoliating products, and achieve the effects of excellent thixotropy, stable and homogeneous viscosity, and good feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

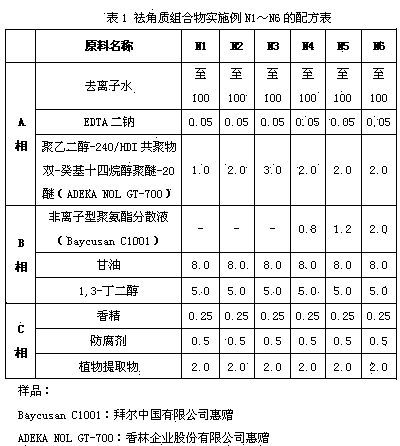

[0047]

[0048] Preparation Process:

[0049] Step 1: Add the non-ionic emulsifier and disodium EDTA in phase A into deionized water, heat up to 80-85°C, stir and mix for 15-20 minutes to ensure uniform dispersion, stir at 150r / min and cool down to 40- 45°C; Mix B-phase non-ionic polyurethane dispersion with humectant, heat to 40-45°C, stir and mix, and disperse evenly;

[0050] Step 2: Slowly add the mixture of phase B to the mixture of phase A, stir and mix, and disperse evenly;

[0051] Step 3: Add plant extracts and additives, stir to disperse, cool down to room temperature, stir slowly for 30 minutes, and then discharge to obtain the exfoliating composition.

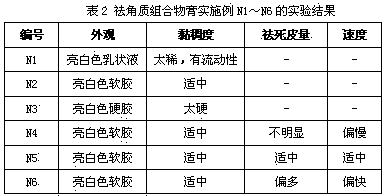

[0052] The experimental results are shown in Table 2.

[0053]

[0054] From the comparison of Examples N1-N3 and N4-N6, it can be fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com