Foaming agent for oilfield, and preparation method thereof

A foaming agent, oil field technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low foaming volume, unusable, poor foam stabilization effect, etc., and achieve high foaming volume and fine foam. Stable, high-quality foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 25kg of α-alkenyl sulfonate (AOS), 10kg of alkylphenol polyoxyethylene ether carboxylate (APEC), and 80kg of fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle, and add ten Dialkyl dimethyl amine oxide 30kg, tetradecyl dimethyl betaine 10kg, glycerol 3kg, stirred for 0.4 hours;

[0016] Continue to add 842kg of water in the kettle and continue stirring for 0.8 hour to obtain a temperature-resistant and salt-resistant foaming agent for oilfields.

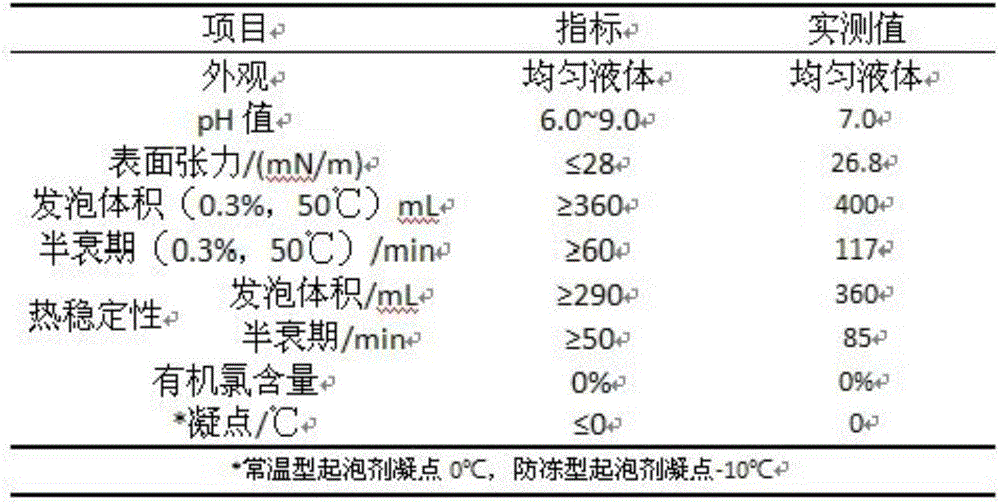

[0017] The performance test of the foaming agent used in normal temperature operation, the foam volume produced by the foaming agent prepared in this example is the most ideal when the concentration is 0.3% and the temperature is 50 ° C. When the concentration exceeds 0.3%, the foam volume is no longer The increase or increase is not obvious, so the performance of the foaming agent is the best at a concentration of 0.3% and a temperature of 50°C. The performance is as follows:

[0018]

Embodiment 2

[0020] Weigh 30kg of α-alkenyl sulfonate (AOS), 20kg of fatty alcohol polyoxyethylene ether salt (AEC), and 80kg of fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle. While stirring, add twelve Alkyl dimethyl amine oxide 30kg, tetradecyl dimethyl betaine 10kg, glycerol 3kg, stirred for 0.4 hours;

[0021] Continue to add 135kg of methanol and 692kg of water to the kettle and continue to stir for 0.8 hours to obtain a temperature-resistant and salt-resistant foaming agent for oilfields.

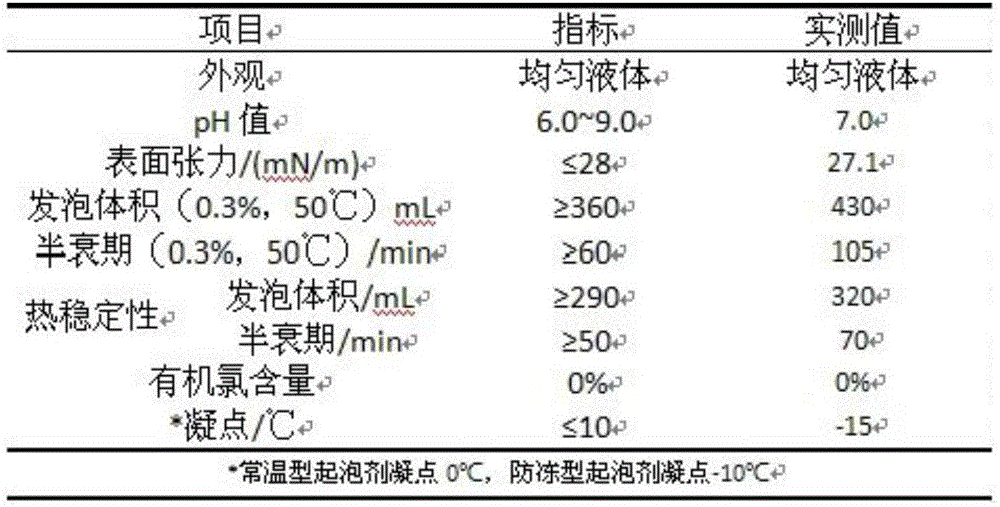

[0022] Through the performance test of the foaming agent for antifreeze operation, the foam volume produced by the foaming agent prepared in this example is the most ideal when the concentration is 0.3% and the temperature is 50°C. When the concentration exceeds 0.3%, the foam volume is no longer The increase or increase is not obvious, so the performance of the foaming agent is the best at a concentration of 0.3% and a temperature of 50°C. The performance is as foll...

Embodiment 3

[0025] Weigh 2 parts of alkylbenzene sulfonate, 3 parts of fatty alcohol polyoxyethylene ether carboxylate, and 60 kg of fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle, stir evenly, and then add dodecyl dimethyl Amine oxide 20kg, tetradecyl dimethyl betaine 10kg, glycerol 1kg, stirred for 0.4 hours;

[0026] B. Add 570 kg of water into the kettle and continue to stir for 0.8 hours to obtain a foaming agent for oil fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com