Phase-change and energy-storage mortar of ternary composite paraffin/glazed hollow beads and preparation method of phase-change and energy-storage mortar

A phase change energy storage mortar and vitrified microbead technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as low latent heat of phase change, improve comfort, improve heat storage effect, and improve water absorption high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

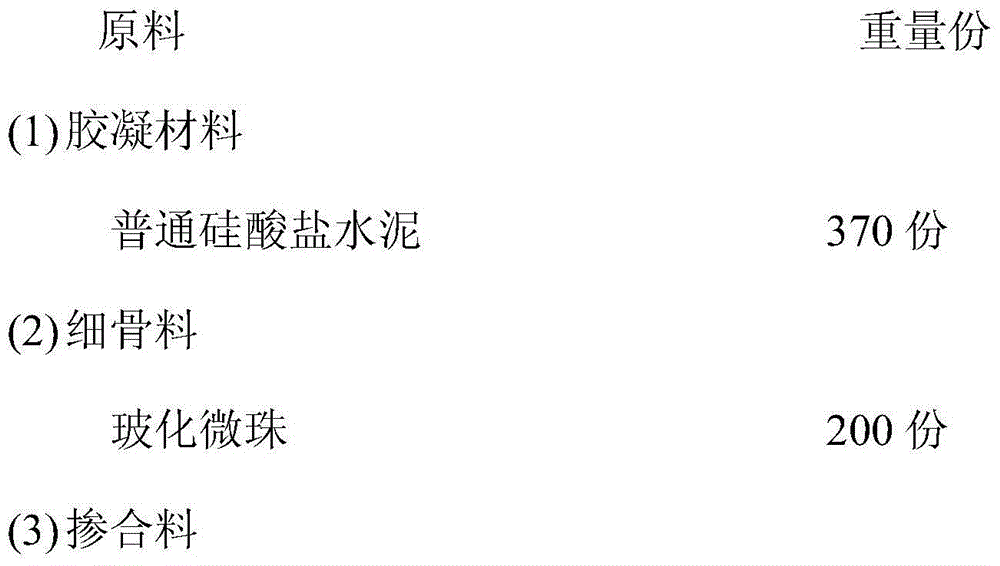

[0020] A ternary composite paraffin / vitrified microbead phase change energy storage mortar, the components of which are:

[0021]

[0022]

[0023] Its preparation process is:

[0024] ⑴ Selection of raw materials:

[0025] Ordinary Portland cement is 42.5 ordinary Portland cement produced by Shenyang Jidong Cement Co., Ltd.;

[0026] Liquid No. 3 paraffin and n-tetradecane are produced by Fushun Beiyuan Fine Chemical Co., Ltd.;

[0027] The solid section paraffin with a melting point of 48-50°C is produced by Sinopharm Shenyang Chemical Reagent Co., Ltd.;

[0028] Vitrified beads are produced by Yongqing County Hengxin Perlite Co., Ltd.;

[0029] Styrene-acrylic emulsion is produced by Nantong Shengda Chemical Co., Ltd.;

[0030] Silica fume is produced by Shenyang Shihuan Mining Co., Ltd.

[0031] ⑵Preparation process

[0032] ① Preparation of paraffin-based ternary composite phase change materials. Weigh the three kinds of paraffin with a balance according to t...

Embodiment 2

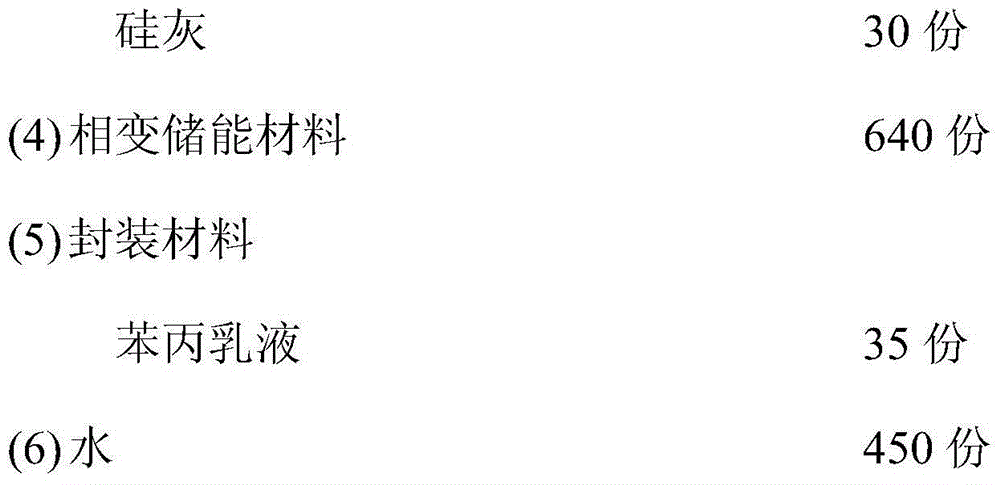

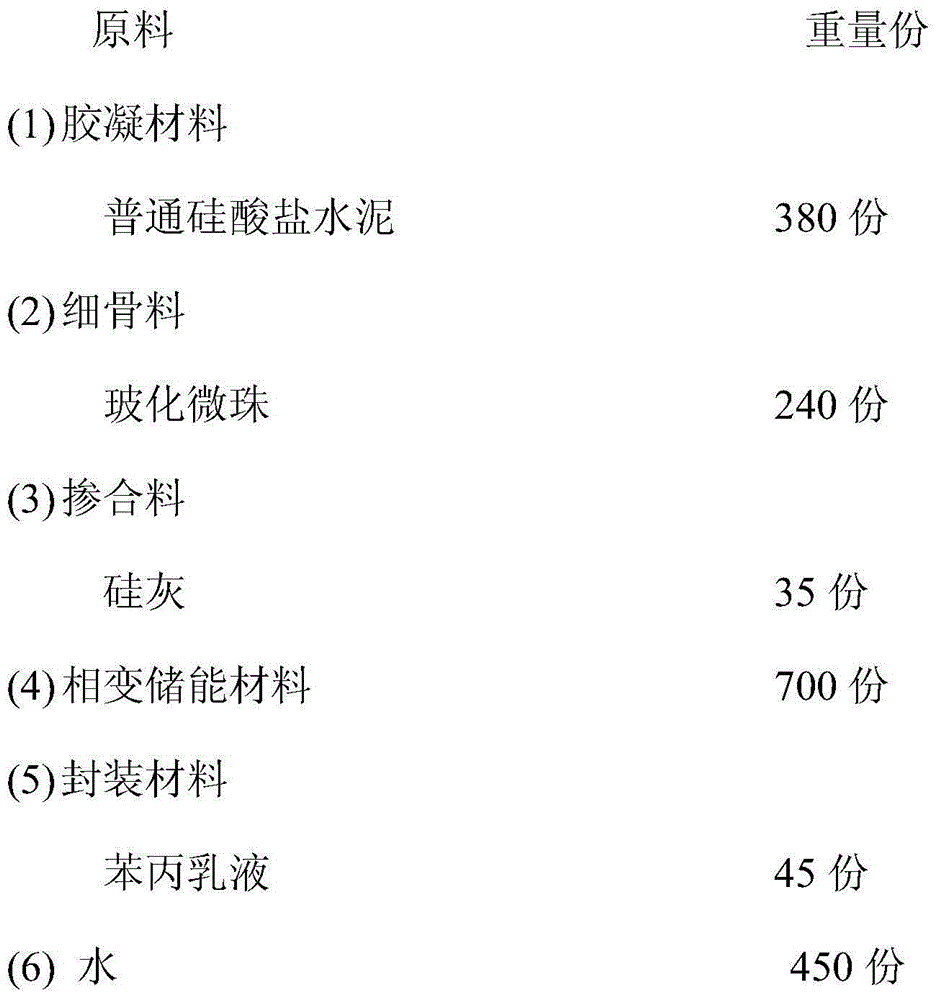

[0039] Ternary compound paraffin / vitrified microbead phase change energy storage mortar, its components are:

[0040]

[0041] Its preparation process is:

[0042] Its preparation process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com