Mthod for controlling roller gap of precision rolling machine of band steel

A control method and finishing mill technology, applied in the direction of rolling force/gap control, contour control, etc., can solve problems such as inaccurate outlet temperature, inaccurate outlet thickness, and affecting the quality of finished strip products, so as to improve thickness accuracy and yield, improve the accuracy and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

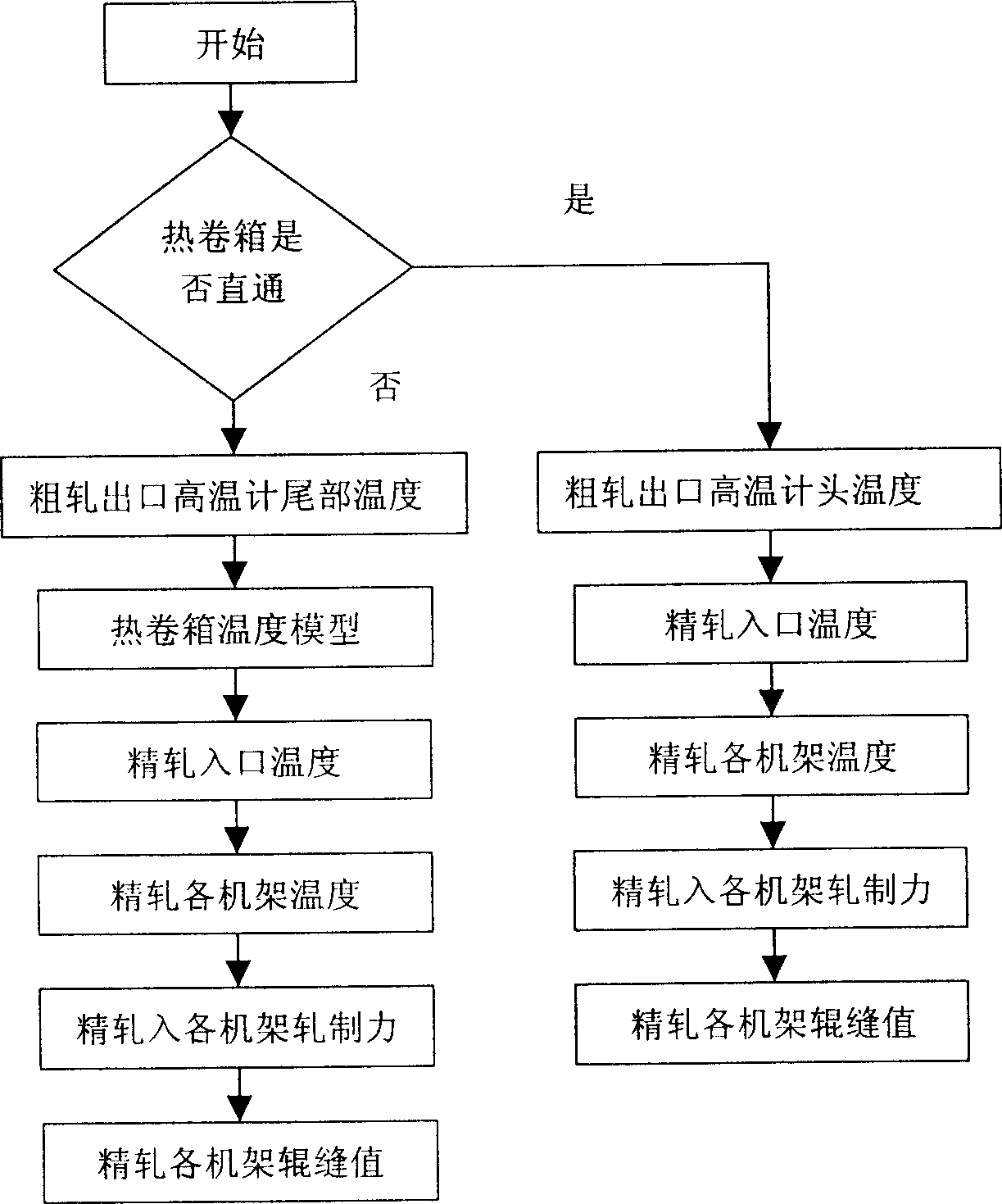

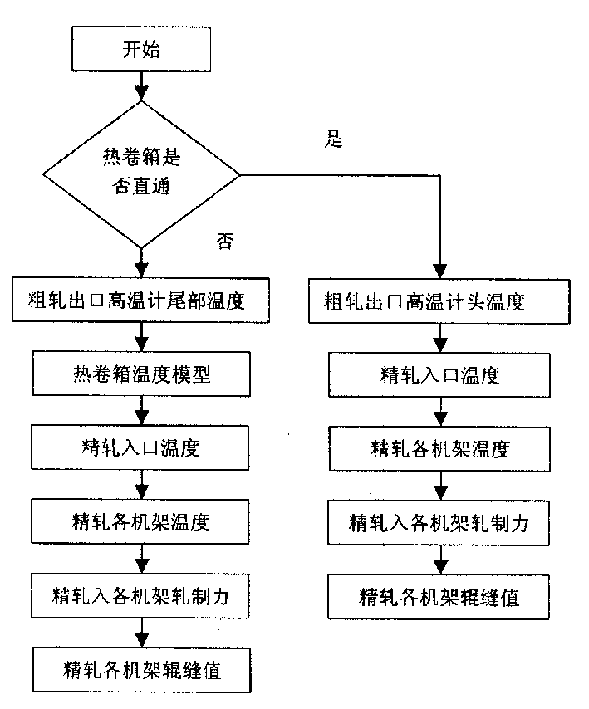

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, the control method of the roll gap of the strip steel finishing mill of the present invention mainly includes the temperature value of the finish rolling entrance, the temperature value of each finish rolling stand, the rolling force value of each finish rolling stand, and the finish rolling each stand by the computer. The calculation of the roll gap value of the frame is set to the first-level computer, which controls the PLC, and adjusts the pressing motor and hydraulic device to adjust the roll gap through the PLC. The mathematical model of the finish rolling inlet temperature is:

[0026] FET=RDT-αH-βGD-γL+δ

[0027] Among them: FET———finishing entrance temperature;

[0028] RDT————The actual temperature at the end of the R2 exit of the roughing mill, and its value is determined by the pyrometer at the exit of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com