A production control method of narrow strip steel for die cutting

A production control method and technology for narrow strip steel, applied in the field of metallurgy, can solve the problems of small enterprise scale, poor steel quality, single variety, etc., and achieve the effect of improving load capacity, good bending performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a production control method of narrow strip steel for die cutting. This method produces high-strength narrow strip steel for die cutting through temperature control, controlled rolling, and improving the backing plate structure of the lower rollers of the finishing mill. The specific operations are as follows :

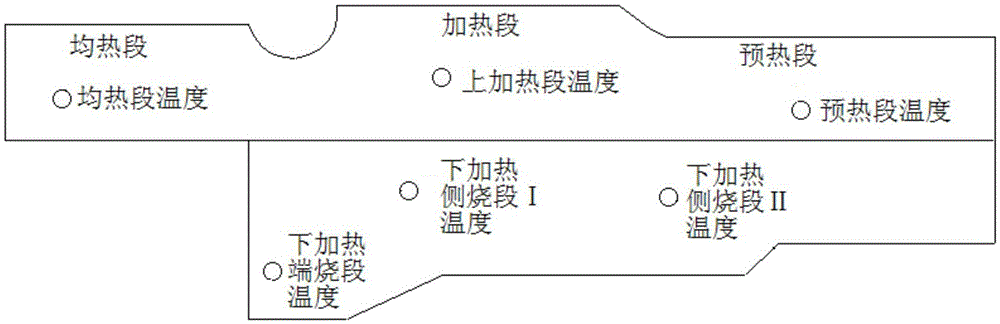

[0038] (1) Temperature control process

[0039] (1) First send the stainless steel billet with a diameter of 500mm and a thickness of 37mm into the heating furnace for preheating, and the temperature in the preheating section is controlled at 600°C;

[0040] (2) After the internal and external temperature of the preheated stainless steel billet in step (1) is the same, it is sent to the heating section for heating. The temperature is 1250°C, the temperature of the lower heating end firing section II is 1100°C, and the position of the temperature of the lower heating end firing section I is between the temperature of the lower heating s...

Embodiment 2

[0053] This example provides a method for controlling the production of narrow strip steel for die cutting. This method produces high-strength narrow strip steel for die cutting through temperature control, controlled rolling, and improving the backing plate structure of the lower rollers of the finishing mill. The specific operations are as follows :

[0054] (1) Temperature control process

[0055] (1) First send the stainless steel billet with a diameter of 500mm and a thickness of 37mm into the heating furnace for preheating, and the temperature in the preheating section is controlled at 700°C;

[0056] (2) After the internal and external temperature of the preheated stainless steel billet in step (1) is the same, it is sent to the heating section for heating. The temperature is 1200°C, the temperature of the lower heating end firing section II is 1200°C, and the position of the temperature of the lower heating end firing section I is between the temperature of the lower ...

Embodiment 3

[0068] This example provides a method for controlling the production of narrow strip steel for die cutting. This method produces high-strength narrow strip steel for die cutting through temperature control, controlled rolling, and improving the backing plate structure of the lower rollers of the finishing mill. The specific operations are as follows :

[0069] (1) Temperature control process

[0070] (1) First send the stainless steel billet with a diameter of 500mm and a thickness of 37mm into the heating furnace for preheating, and the preheating temperature is controlled at 750°C;

[0071] (2) After the internal and external temperature of the preheated stainless steel billet in step (1) is the same, it is sent to the heating section for heating. The temperature of I is 1300°C, the temperature of lower heating end firing section II is 1150°C, and the position of the temperature of lower heating end burning section I is between the temperature of lower heating side burning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com