Method for controlling transverse rolling width and longitudinal rolling width of moderately-thick plate

A technology of width control and horizontal and vertical rolling, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as large width errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

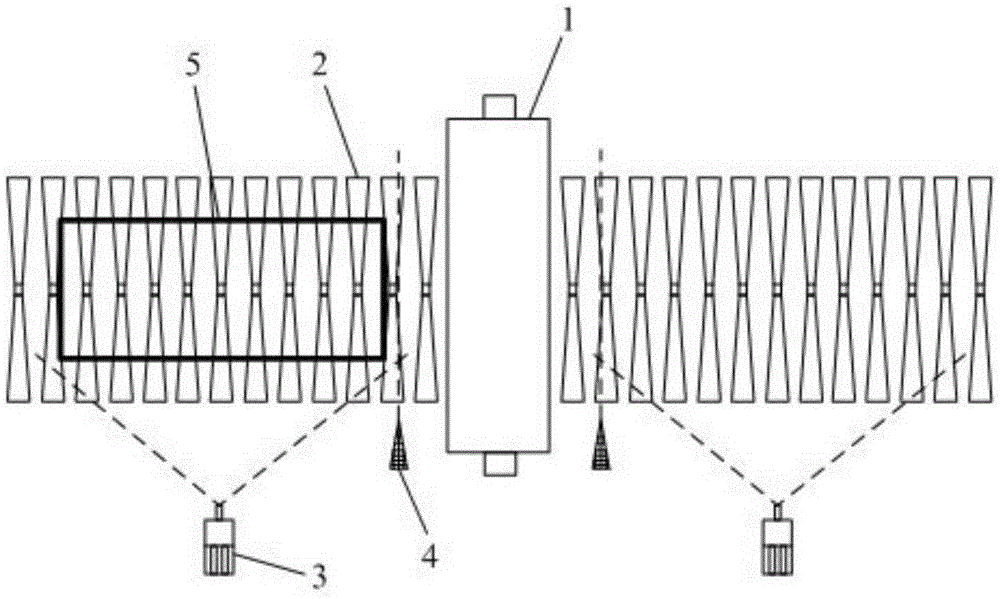

[0033] Such as figure 2 As shown, the present invention respectively installs an industrial CCD camera 3 and a metal detector 4 at the front and back of the rolling mill 1, and ensures that each camera can simultaneously photograph the rolled piece 5 on the roller table 2 by adjusting the distance between the camera and the roller table shape of the head and tail.

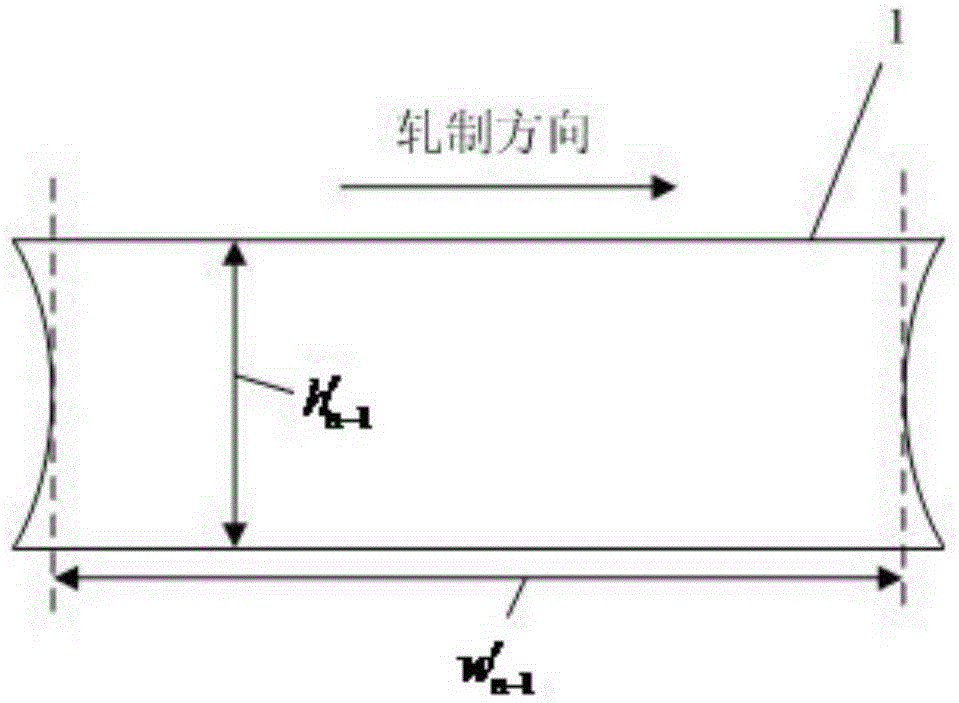

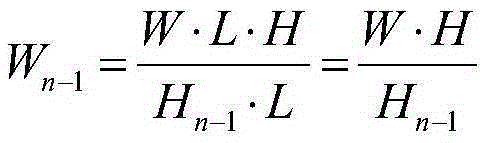

[0034] The present invention considers that on the basis of the prior art, the exit thickness of the cross-rolling stage and the reduction of each pass are firstly set according to the prior art, and the reduction of the previous pass is set according to the maximum allowable rolling mill. The load is set to control the width by adjusting the reduction amount of the last pass. Assuming that the rolled piece is always a standard rectangular body, the exit thickness, reduction and correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com