Purification method and device for filling machine

A technology of purification device and filling machine, which is applied to chemical instruments and methods, cleaning methods using liquids, cleaning of filling devices, etc., can solve the problems of reduced productivity of beverage filling containers, downtime (longer production downtime, etc.) The effect of shortening production downtime, preventing poor cleaning, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

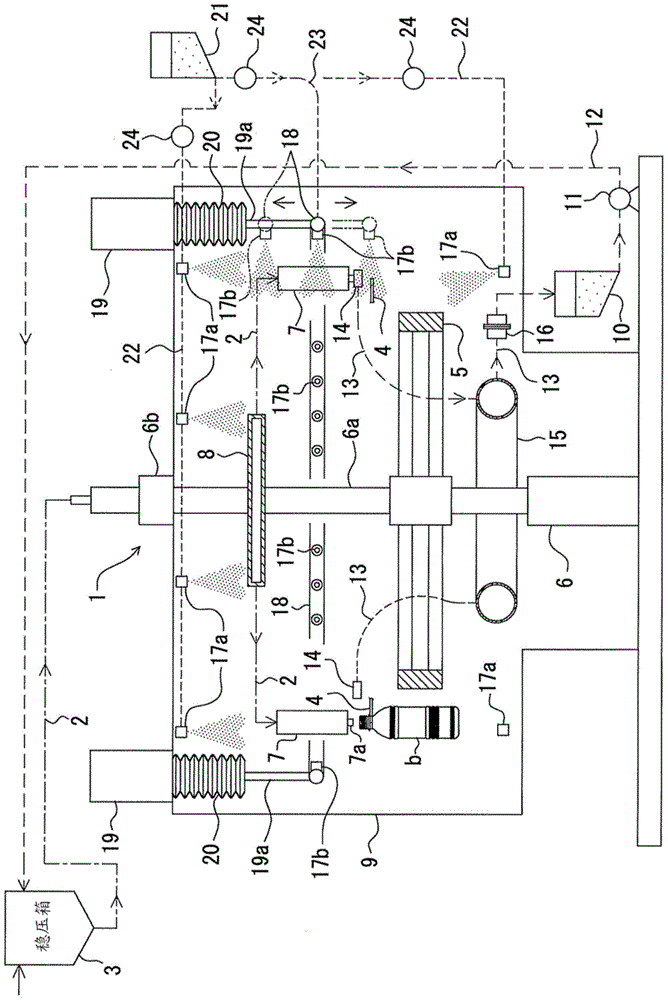

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0044]In the aseptic filling device, there is a brewing tank not shown in the beverage to figure 1 The shown filling machine 1 supplies a beverage supply line 2 with a beverage. exist figure 1 In , reference numeral 3 denotes a surge tank provided in the middle of the piping of the beverage supply system.

[0045] In addition, the aseptic filling device is provided with a bottle conveying path for conveying the bottle b, which is a container filled with beverage, to the filling machine 1, and conveying the bottle b filled with the beverage by the filling machine 1 to a capping machine not shown. The conveyance path is usually formed by combining a plurality of gears in a row. Furthermore, tongs 4 and the like are arranged at regular intervals around the respective wheels.

[0046] The filling machine 1 is a filling machine that fills beverages into a plurality of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com