Quick change type cooling water joint for continuous caster sector driving roller

A continuous casting machine sector and drive roller technology, applied in mechanical equipment, couplings and other directions, can solve the problems of inability to realize quick change, inability to realize rotation, poor sealing and easy water leakage, etc., to achieve convenient disassembly and assembly, reduce Operation time, the effect of reducing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

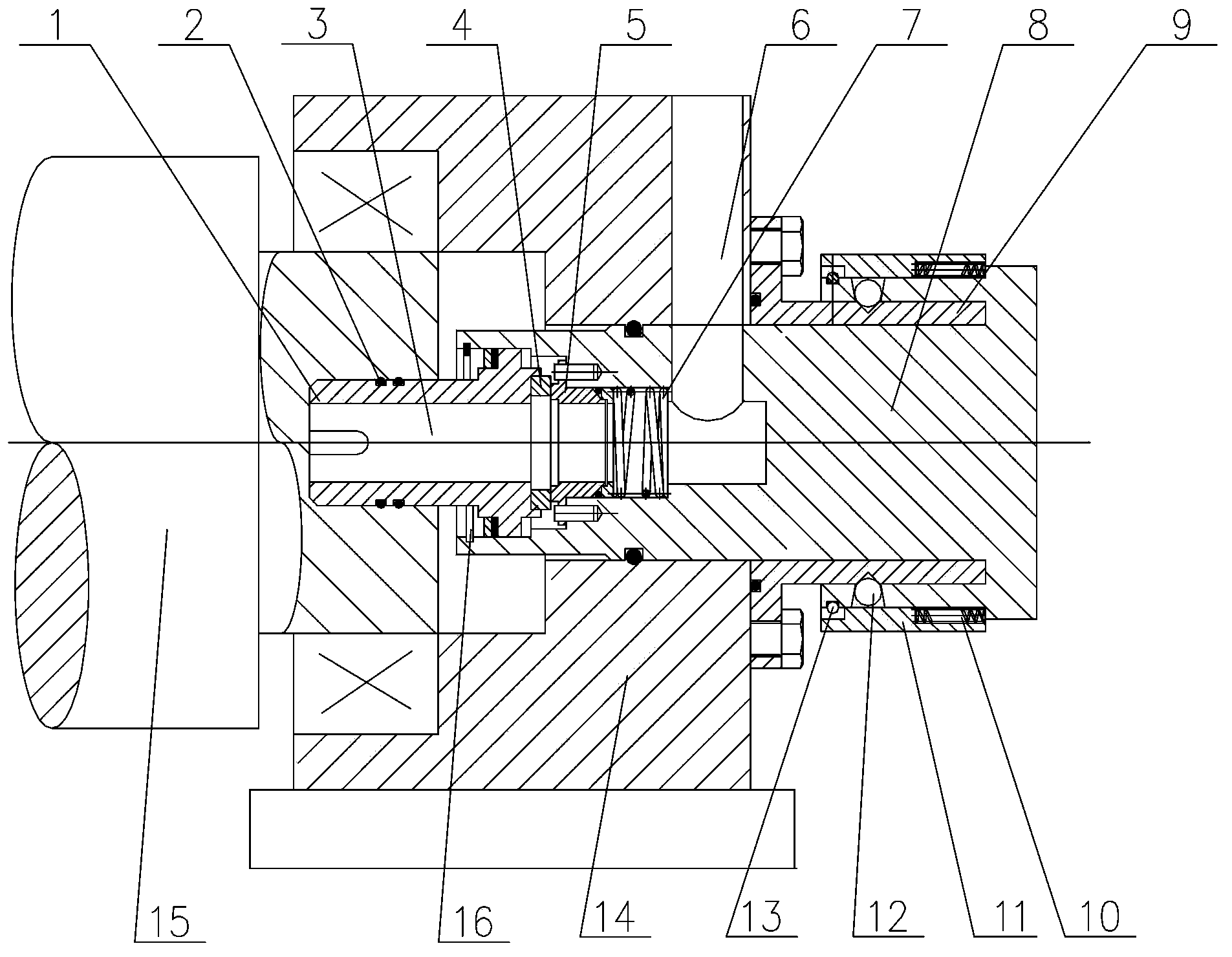

[0012] The quick-change cooling water joint of the drive roller of the continuous casting machine segment shown in the figure includes a fixed joint body 8 arranged in the through hole of the base 14 of the drive roll of the sector segment. The front mounting hole of the fixed joint body 8 is provided with a The rotary joint body 1 connected with the transmission roller 15 of the sector section, the water outlet 3 of the rotary joint body 1 communicates with the water inlet 6 of the fixed joint body 8, and the inner end of the rotary joint body 1 passes through the metal pad 4, the copper sleeve 5 and the compression spring in sequence 7, and the end of the front mounting hole of the fixed joint body 8 is provided with a circlip 16 matched with the rotary joint body 1 . The rear section of the fixed joint body 8 is fitted with a flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com