Steady brake control system for multiple constant tension windlasses used in pipe-laying ships

A braking control, constant tension technology, applied in the direction of comprehensive factory control, electrical program control, ships, etc., can solve the problems of low reliability of the control system, difficult to achieve, unstable braking process, etc., to reduce production downtime and smooth braking. , smooth movement and positioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

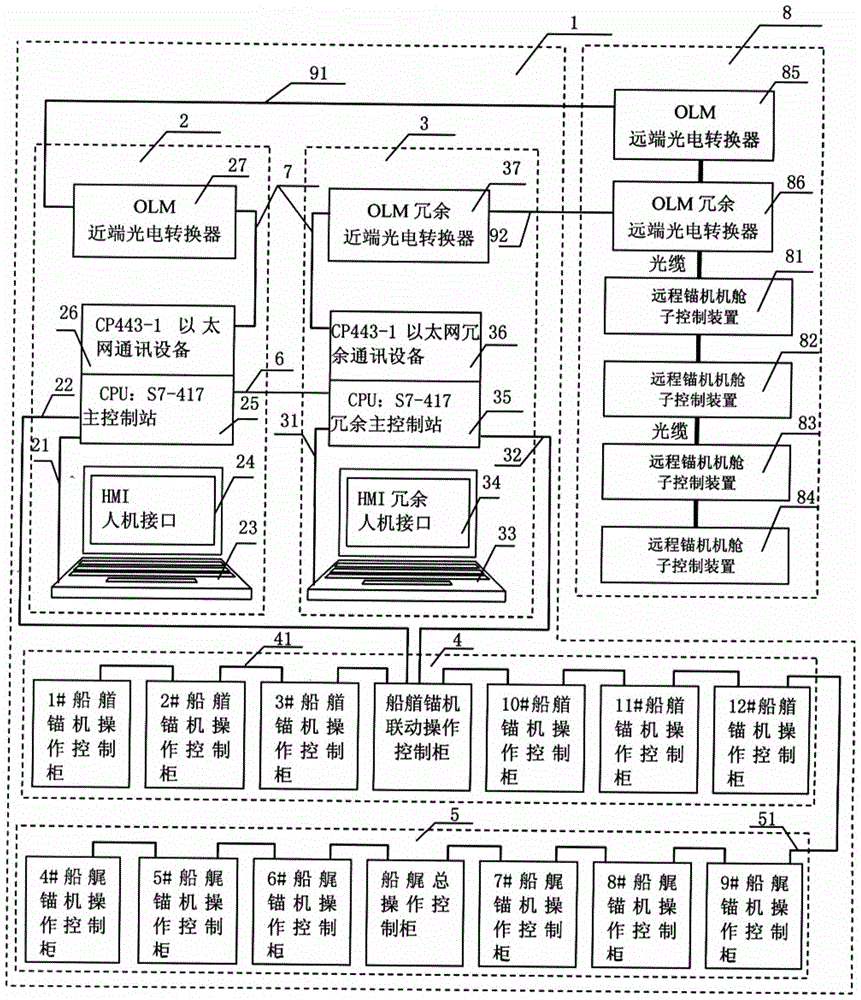

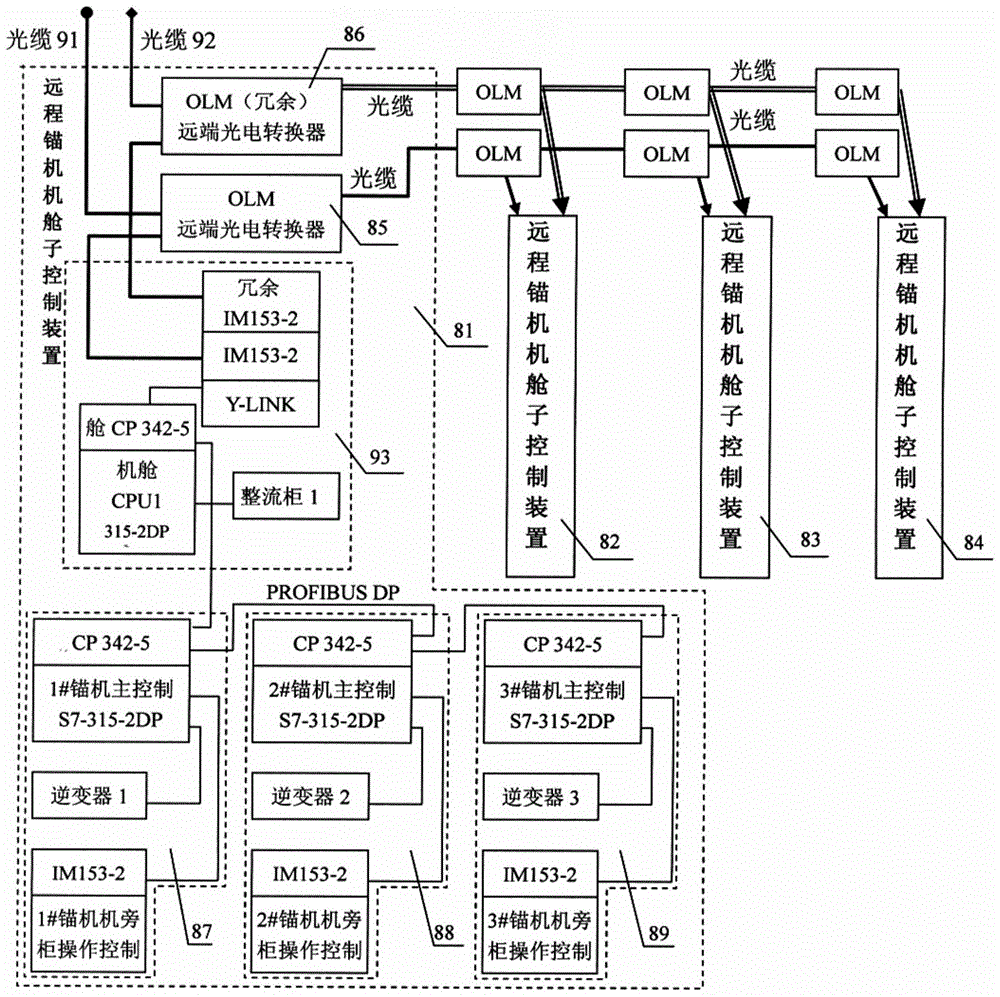

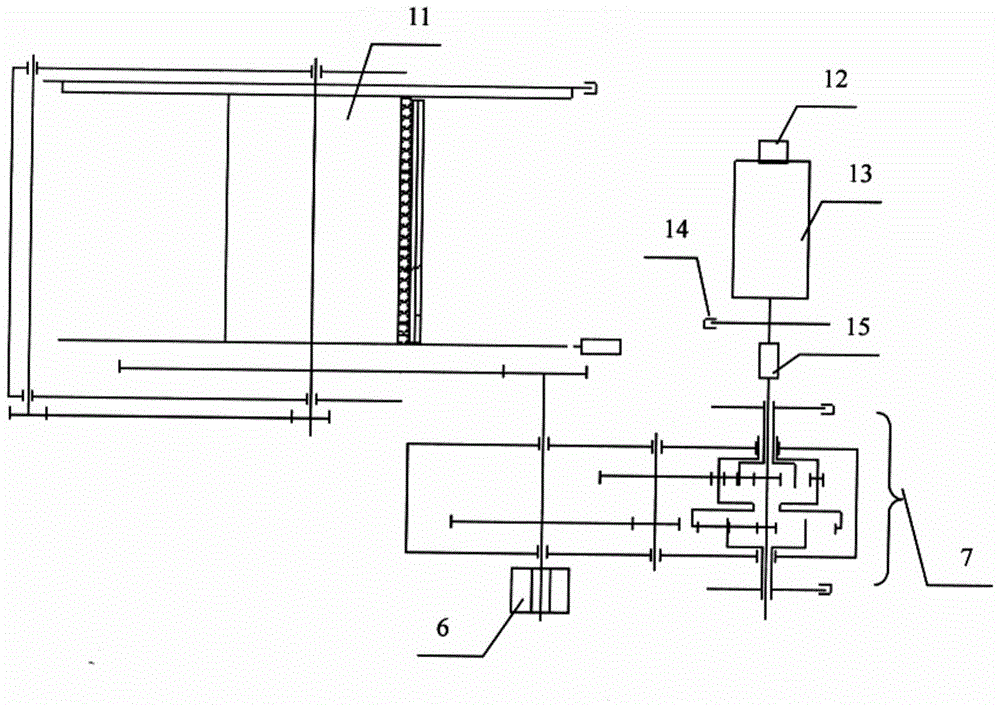

[0023] Such as Figure 1-4As shown, the present invention mainly includes two parts: the cockpit operation control center 1 and the remote windlass engine room control device 8, wherein the cockpit operation control center 1 includes: the cockpit located in the center of the bow console of the cockpit Monitoring center 2, redundant cockpit monitoring center 3 connected to cockpit monitoring center 2 through communication bus 6, bow windlass operation console connected to cockpit monitoring center 2 and redundant cockpit monitoring center 3 respectively, and The stern windlass operation console linked with the bow windlass operation console; among them, the bow windlass operation console is composed of the bow windlass linkage operation console and the corresponding bow windlass linkage operation control cabinet 4, several ships The bow windlass operation console and several corresponding bow windlass operation control cabinets are connected, and the bow windlass linkage operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com