Intelligent supervisory system applied to flame-retarding conveying belt under coal mine

A monitoring system and conveyor belt technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problem of unfavorable product information collection, product quality improvement, inability to timely understand product usage, affecting coal mine production and maintenance efficiency, etc. problems, to achieve the effect of automatic and fast information collection and processing, timely and comprehensive input, and improvement of product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

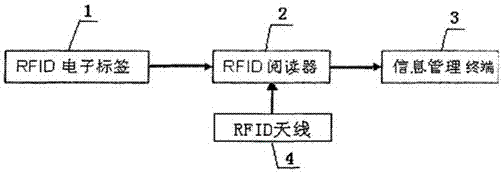

[0033] combine figure 1 , an intelligent monitoring system applied to flame-retardant conveyor belts used in underground coal mines. The system mainly includes RFID electronic tags, RFID readers, RFID antennas and information management terminals installed inside the conveyor belt products. The RFID reader is connected to the information management terminal, and the RFID reader reads the signal on the electronic label and transmits it to the information management terminal. The RFID reader is a fixed reader installed at the node of the production line The RFID electronic tag is installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com