Automatic detection device for distinguishing processing quality of each production procedure of battery

An automatic detection device and processing quality technology, applied in the direction of measuring devices, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of unsatisfactory production quality management, instability, etc., and achieve fast detection speed and detection reliability High, guaranteed product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

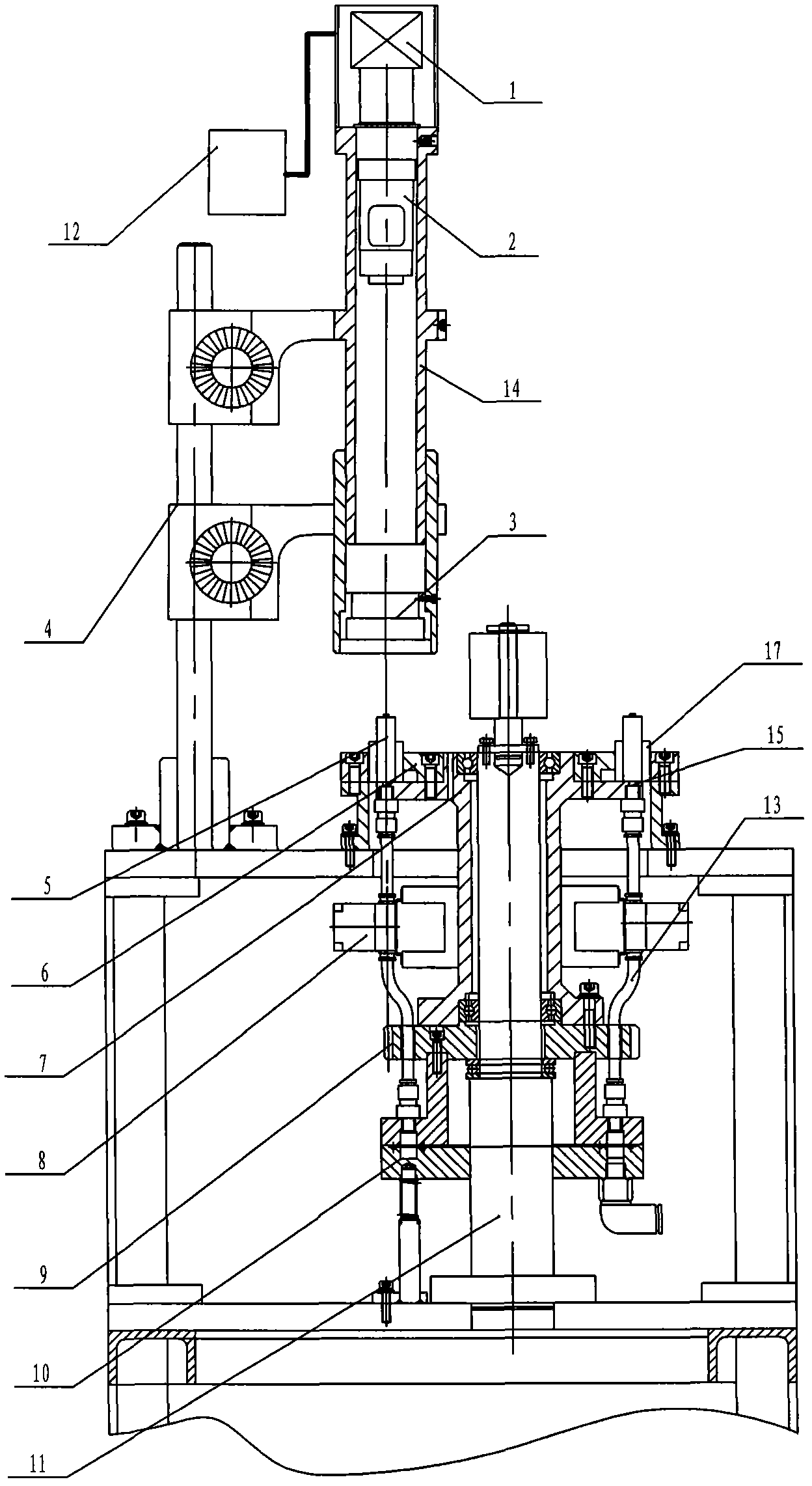

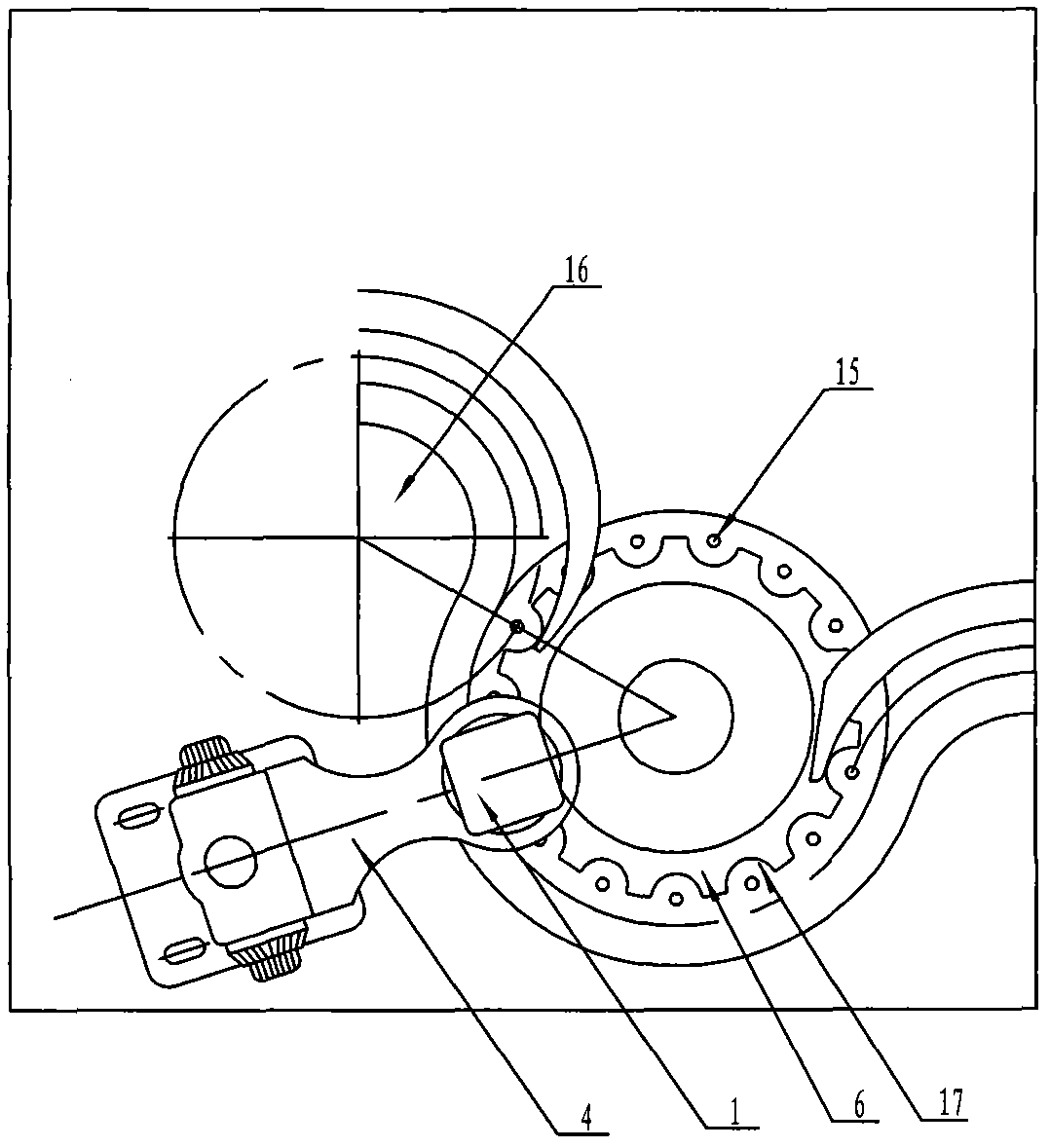

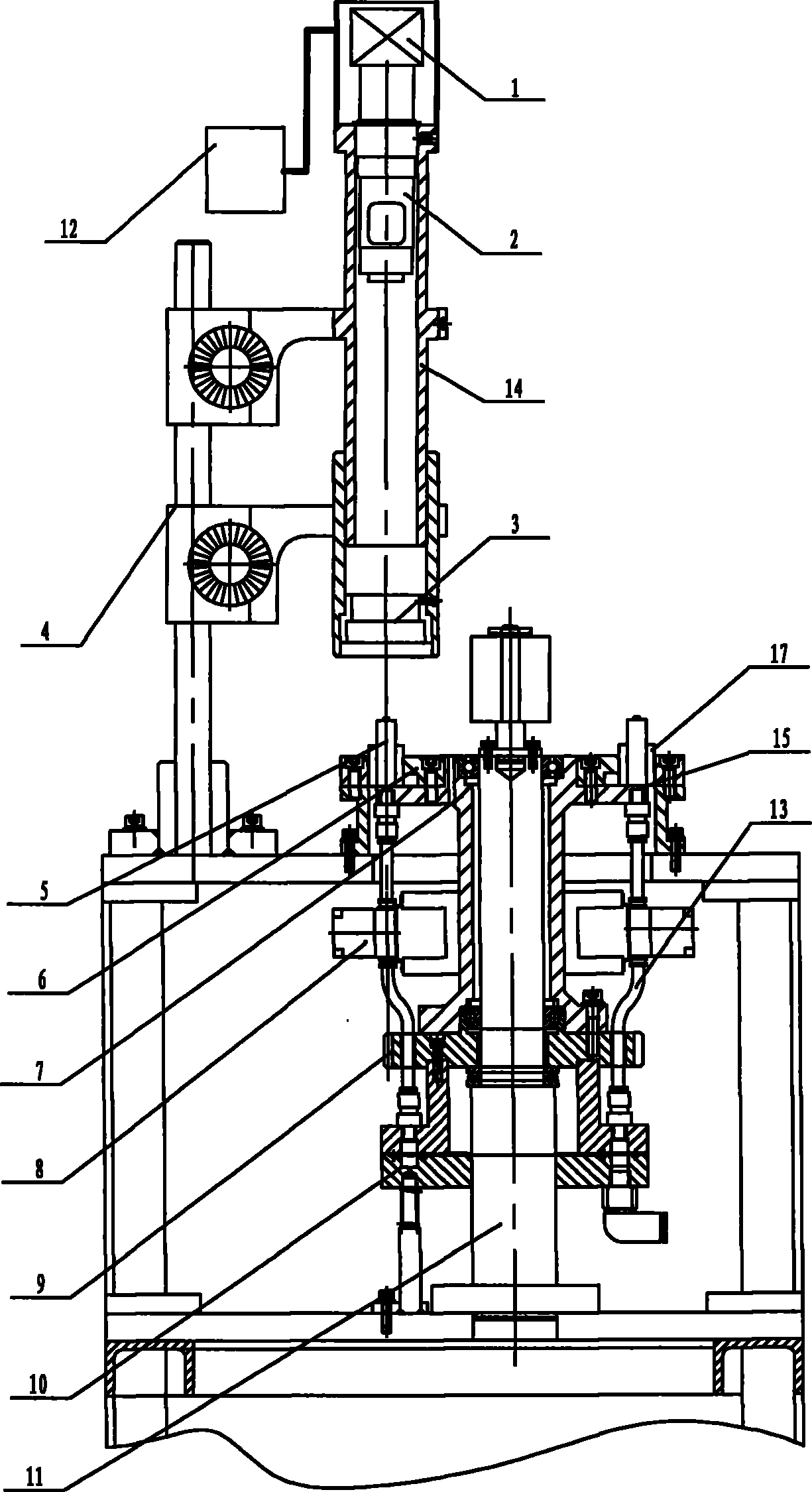

[0014] Such as figure 1 , 2 As shown, the automatic detection device for distinguishing the processing quality of each production process of the battery is composed of a digital camera 1, a microcontroller 12, a frame 4, a rotary chuck 6, and a high-pressure air pipe 13. The rotary chuck 6 is arranged on the frame 4, and the periphery of the rotary chuck 6 is distributed with a plurality of battery clamping positions 17 at intervals along the circumferential direction, and the bottom of each battery clamping position 17 is provided with air holes 15, and each air hole 15 corresponds to a high-pressure air pipe 13 and Connect with the high-pressure air pipe 13, each high-pressure air pipe 13 is provided with a solenoid valve 8, the digital camera 1 is arranged on the top of the rotary chuck 6 and its lens is directly facing the battery clamping position 17, and the digital camera 1 will capture the image of the battery The data information is transmitted to the microcontroller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com