An end panel group of a press for ceramic products and the like

An end plate, component technology, applied in the direction of ceramic forming lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

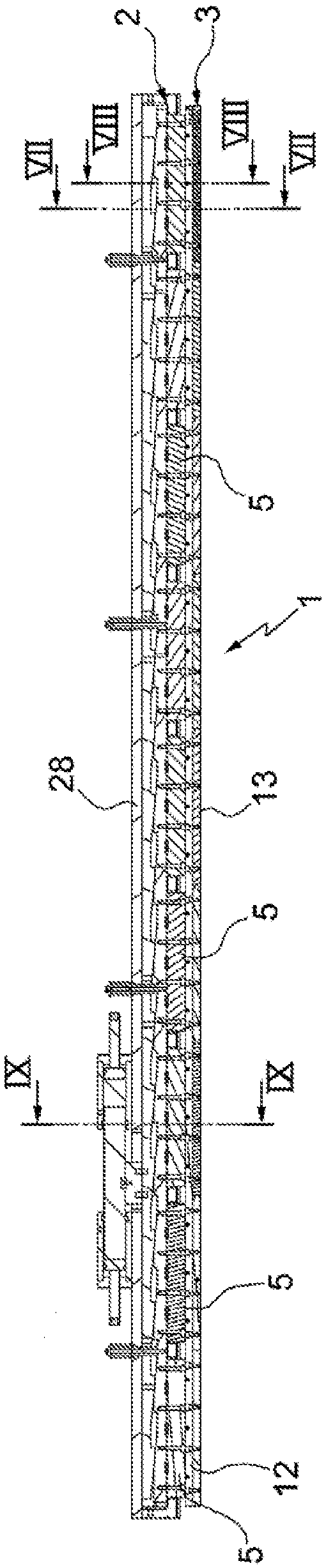

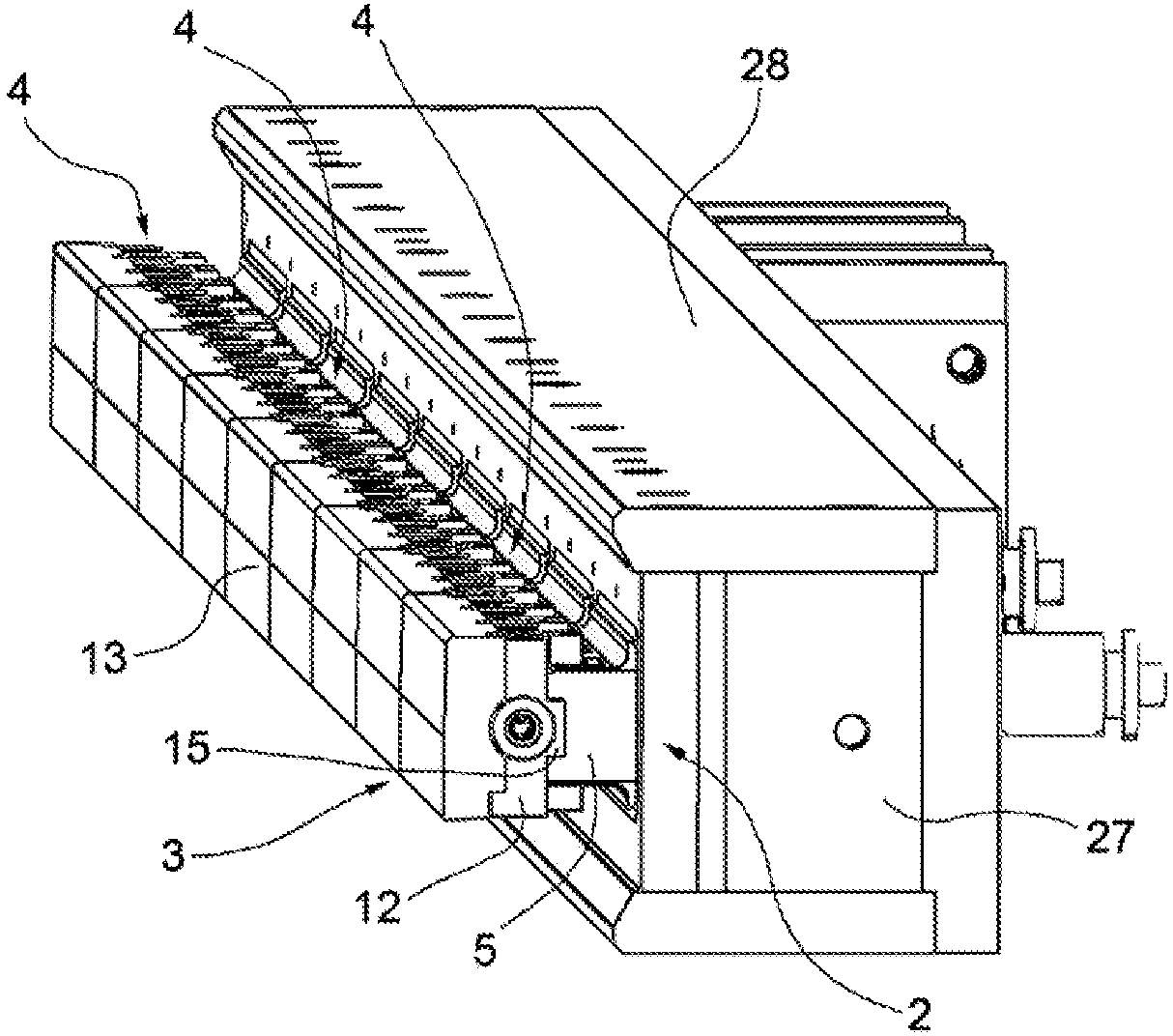

[0034] Referring to the drawings, an end plate assembly for a press for ceramic products and the like according to the present invention is indicated generally by reference numeral 1 .

[0035] According to one version of the invention, the end plate assembly 1 can be mounted on a press for pressing powdered material in order to manufacture ceramic products such as tiles, plates and the like.

[0036] Still according to a version of the invention, the end plate assembly 1 can be mounted on a press for large-sized ceramic products such as tiles or plates with a surface area even reaching several square meters.

[0037] The ceramic material to be extruded for obtaining the above-mentioned products can generally be chosen without any particular limitation between ceramic powders, which can be mixed with additional substances if desired according to the requirements of the particular embodiment.

[0038] The press on which the end panel group 1 can be mounted is not shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com