Operating device

An operating device and operating technology, applied to the device for coating liquid on the surface, metal processing, metal processing equipment, etc., can solve the problems of less than fully automatic operating devices and uneven accuracy of workpiece installation positions, and shorten production stop time , The effect of reducing time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

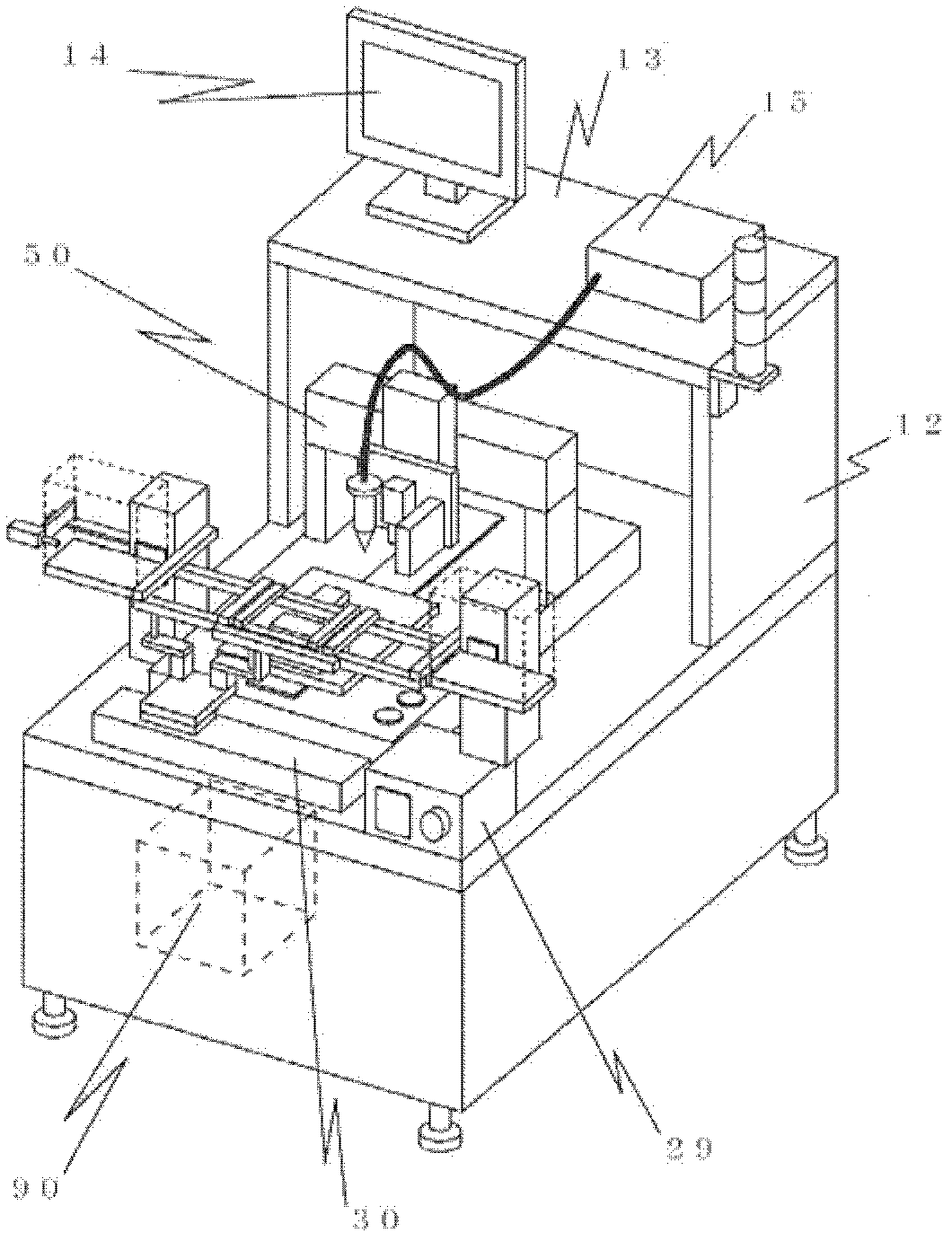

[0137] Embodiment 1 relates to a liquid material application device for applying a liquid material to a lead frame as a workpiece, and includes a main body 10 provided with an operation box 29 and a conveyance unit 30 , and a table-top working device unit 50 as main components. essentials.

[0138] The work of this embodiment is a lead frame in which a plurality of devices are arranged in a lattice, and a hole is formed at the upper right end.

[0139] [body 10]

[0140] The main body 10 is composed of a transport unit 30 and an operation box 29 arranged in front of the base (stand) A11, and a touch panel 14 is arranged on a board 13 supported by two side boards 12 at the rear of the base A11. And batching controller 15 and constitute. In addition, a control unit A90 is disposed below the base A11. In the center of the base A11 is arranged a desktop work implement unit 50 .

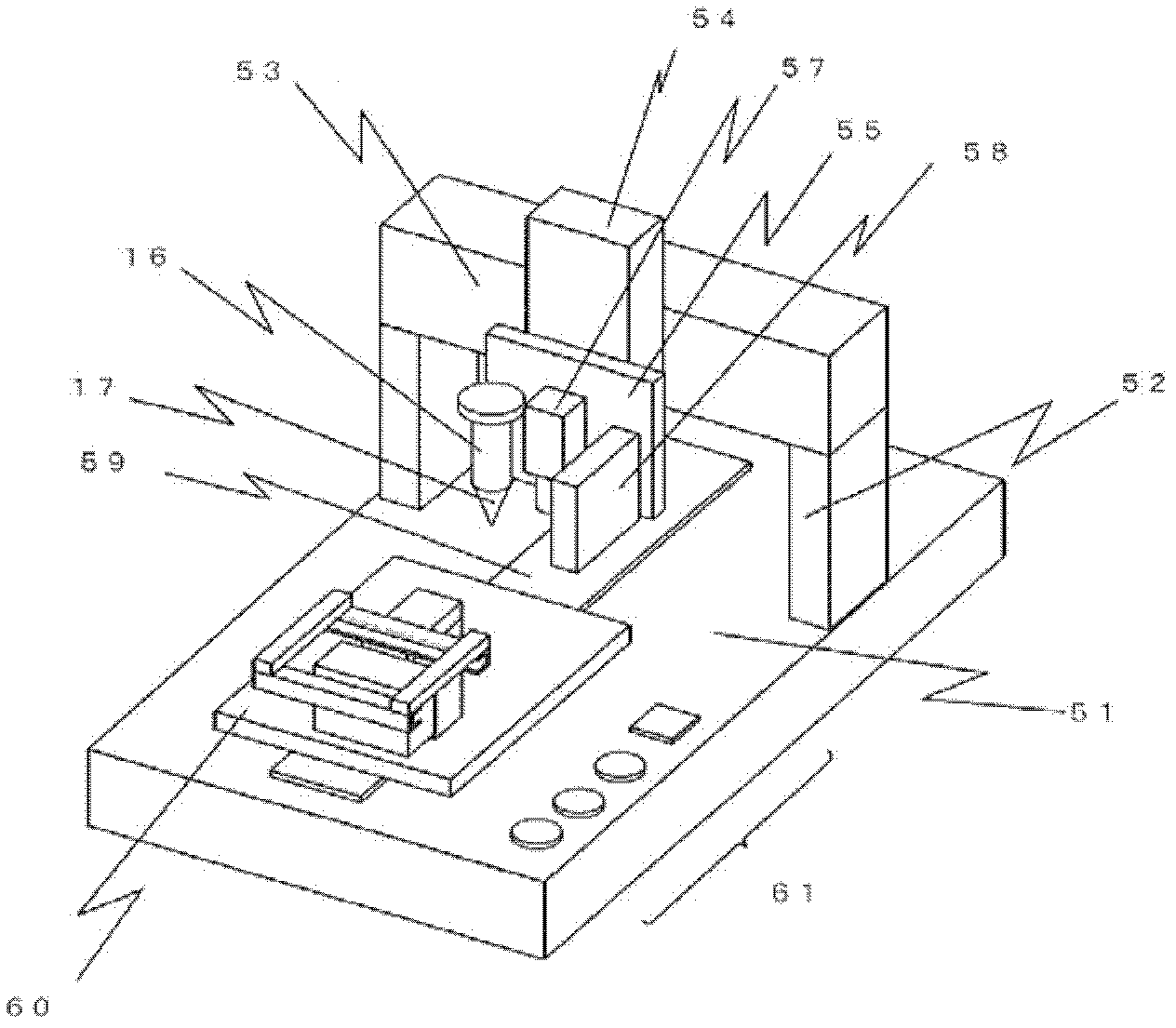

[0141] [desktop work equipment unit 50]

[0142] The desktop work device unit 50 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com