High-precision plunger forming process

A molding process and high-precision technology, applied in the field of plunger pumps, can solve the problems of low efficiency of plunger processing and labor consumption, and achieve the effects of increasing production output, saving processing time, and saving power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

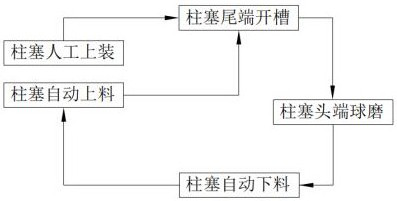

[0068] Such as figure 1 As shown, a plunger high-precision forming process includes the following steps:

[0069] Step 1: Plungers are manually installed. Firstly, several plungers are manually installed on the rotating assembly 13 in sequence for the first time, and the rotating assembly 13 is switched to the slotting station 102 driven by the turntable 12;

[0070] Step 2: The tail end of the plunger is slotted, the engaging part 133 moves to the second drive assembly 22, the clamping assembly 34 cooperates with the positioning shaft 1342 to complete the clamping of the plunger, and the slotting mechanism 3 performs slotting work on the plunger, After all the plungers complete the slotting work, the first driving assembly 21 drives the turntable 12 to continue to rotate and drive it to switch to the ball milling station 103;

[0071] Step 3: Ball milling at the head end of the plunger, the ball milling mechanism 5 completes the ball milling work on each plunger in turn; aft...

Embodiment 2

[0077] The components in this embodiment that are the same as or corresponding to those in the above embodiment use the corresponding reference numerals. For the sake of simplicity, only the differences from the above embodiment will be described below. The difference between this embodiment and the above-mentioned embodiment is:

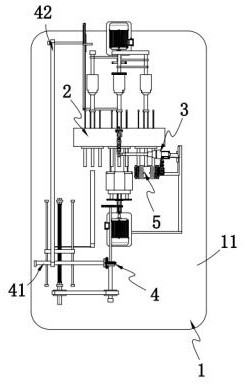

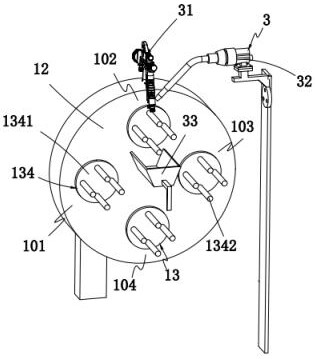

[0078] Such as figure 2 As shown, an automatic production device for plunger pump body accessories includes: a carrying mechanism 1, and the carrying mechanism 1 is sequentially provided with a feeding station 101, a slotting station 102, a ball milling station 103 and a lower material station 104;

[0079] A driving mechanism 2, the driving mechanism 2 drives several groups of component units on the carrying mechanism 1 to sequentially transmit to each station;

[0080] A slotting mechanism 3, the slotting mechanism 3 is arranged on the slotting station 102 and it is used to perform circular slotting work on the component units on the slotting s...

Embodiment 3

[0125] The components in this embodiment that are the same as or corresponding to those in the above embodiment use the corresponding reference numerals. For the sake of simplicity, only the differences from the above embodiment will be described below. The difference between this embodiment and the above-mentioned embodiment is:

[0126] further, such as Figure 9 As shown, the feeding assembly 41 includes:

[0127] The input assembly 411, the input assembly 411 includes an input channel 4111 coaxially arranged with the positioning shaft 1342 at the lower end, a push rod 4112 slidingly arranged in the input channel 4111, and a push rod 4112 for driving the push rod 4112 to advance The screw nut unit 4113 and the first synchronous wheel 4114 for driving the screw nut unit 4113 to start, the workpieces are sequentially matched and lying in the input channel 4111; and

[0128] The first linkage assembly 412, the first linkage assembly 412 includes a first driving gear wheel 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com