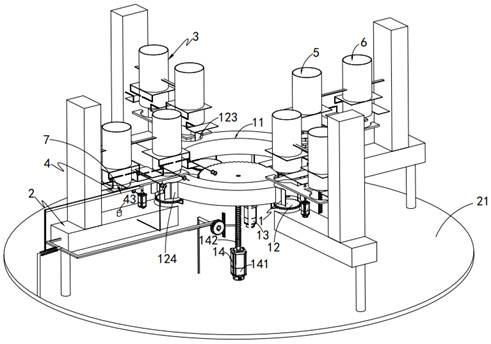

Quick assembling equipment for anti-stroboscopic square bubble of thunder guest

An assembly equipment and anti-flicker technology, applied in assembly machines, metal processing equipment, metal processing, etc., can solve the problems of insufficient product stability, time-consuming cost, high labor cost, etc., achieve stable tightness, reduce production costs, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

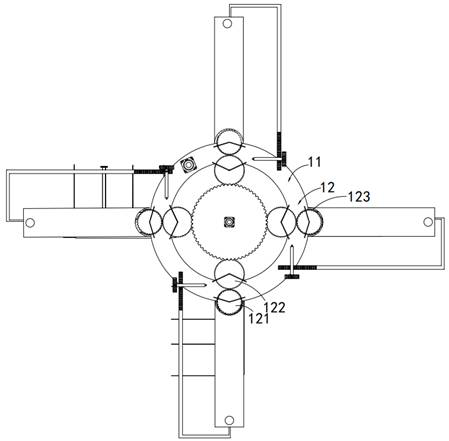

Embodiment 1

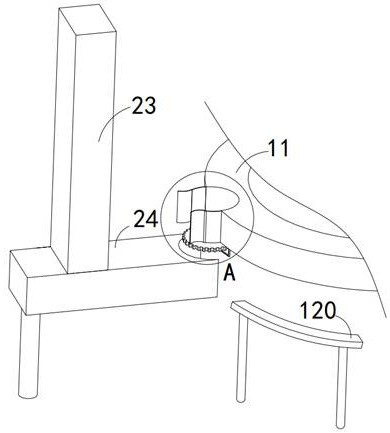

[0056] The transmission unit 423, the transmission unit 423 is provided with two groups and respectively corresponding to the two groups of the clamping parts 422, the transmission unit 423 includes a left drive wheel 4231 coaxial with the splint a4221 and synchronous transmission, and the The left driving wheel 4231 is engaged and the right driving wheel 4232 is coaxially transmitted with the splint b4222, and the lower driving wheel 4233, which is arranged on the switching plate 421 and is engaged with the left driving wheel 4231, and the lower driving wheel 4233 is connected with the lower driving wheel. 4233 coaxial and synchronous upper drive wheel 4234;

[0057] In this embodiment, by setting the clamping part 422 to cooperate with the transmission unit 423, the transmission unit 423 is engaged with the clamping rack 424 during the rotation of the switching plate 421, and the clamping part 422 is clamped after the engagement Work, and then complete the clamping of the co...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com