Semi-automatic assembling process for electronic components for electric appliances

A technology of electronic components and assembly process, which is applied in the field of semi-automatic assembly process of electronic components for electrical appliances. It can solve the problems of inability to quickly assemble spot welding, cumbersome clamping, and inapplicability to mass production, and achieve small horizontal space occupation and high degree of automation. , the effect of saving the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

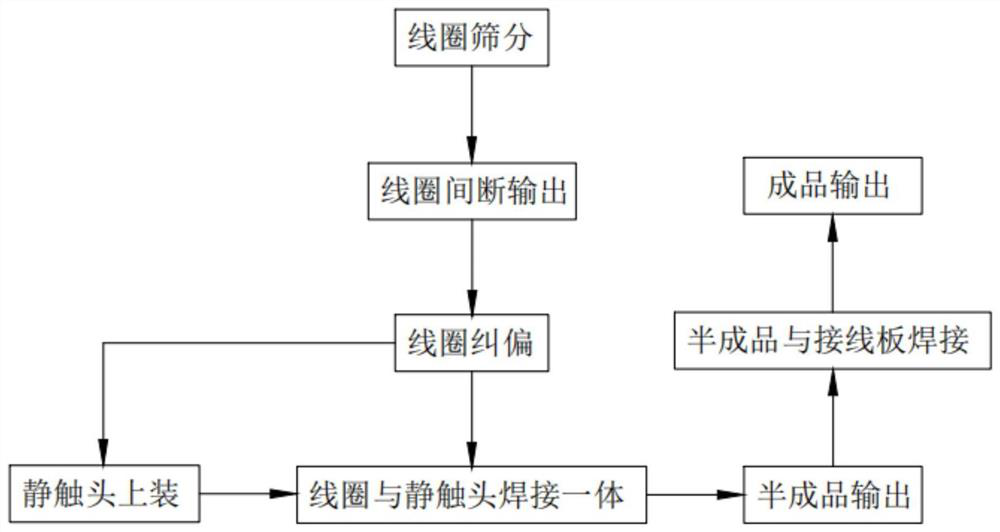

[0088] Such as figure 1 As shown, a semi-automatic assembly process of electronic components for electrical appliances, including:

[0089] Step 1, coil screening, start the first transmission assembly 12, the coil 10 randomly falls between the screw 121 and the optical axis 122, the rotating screw 121 cooperates with the optical axis 122 to drive the coil 10 to automatically lie flat, and faces the height limit mechanism 2-way transmission;

[0090] Step 2, the coil output intermittently, start the second transmission assembly 31, the partition 324 of the spacer assembly 32 is lifted between the corresponding first transmission assembly 12 under the guidance of the first guide assembly 33, and at the same time, the top plate 342 is transferred to the disc When it is directly below 341, the top plate 342 contacts the disc 341 and lifts it up, and a coil 10 smoothly passes through the roller shaft 21 of the height limiting mechanism 2 and outputs backward;

[0091] Step 3, th...

Embodiment 2

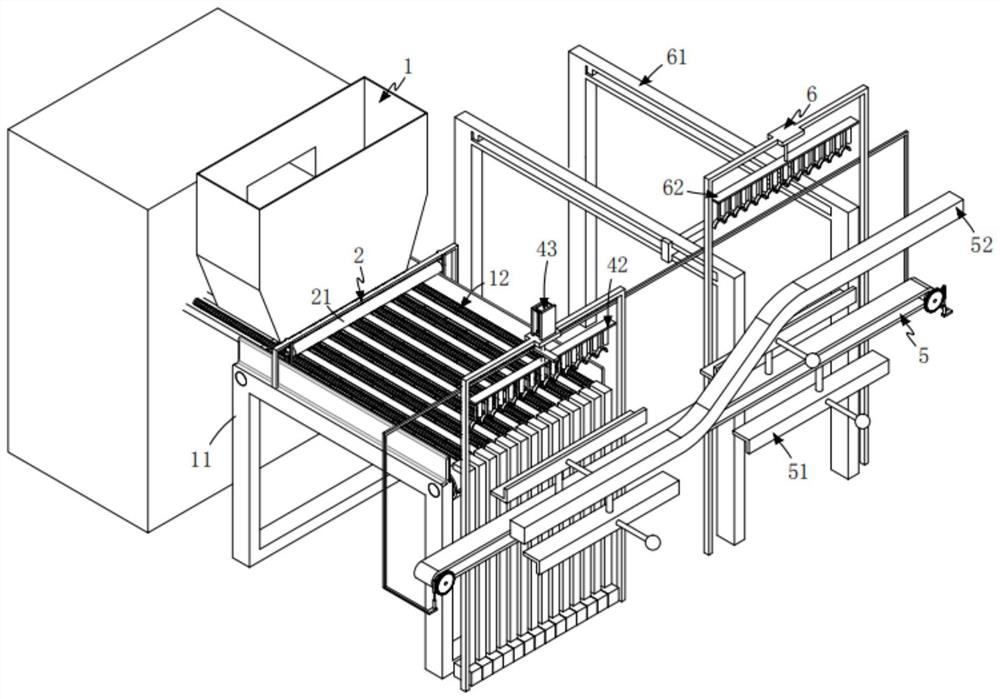

[0108] Such as figure 2 As shown, a semi-automatic assembly equipment for electronic components for electrical appliances, including:

[0109] The laying mechanism 1 includes a frame 11 and several groups of first transmission components 12 that are rotatably arranged on the frame 11 and extend along the length direction of the frame 11. The first transmission components 12. The synchronous transmission is driven by the first driving mechanism 13;

[0110] A height limiting mechanism 2, the height limiting mechanism 2 is installed on the frame 11 and arranged along the width direction of the frame 11, and the roller shaft 21 of the height limiting mechanism 2 is driven to rotate by a third drive mechanism 22;

[0111] The deviation correction mechanism 3, the deviation correction mechanism 3 is arranged below the first transmission assembly 12, which includes a second transmission assembly that is driven along the length direction of the frame 11 and arranged in several grou...

Embodiment 3

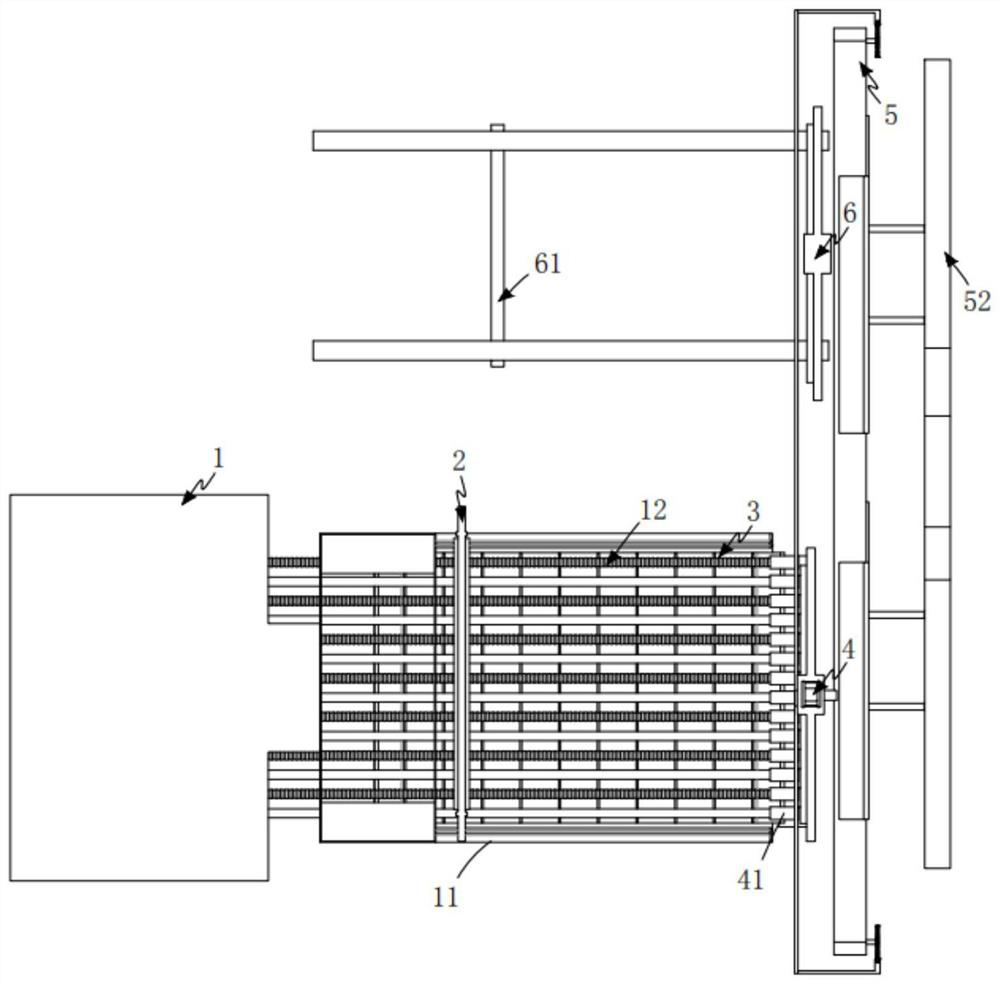

[0162] Such as Image 6 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0163] Such as Image 6 As shown, the fourth transmission assembly 62 includes a connecting rod 621 that is fixedly connected to the connecting frame 434 at one end and is provided in a multi-stage structure, a second welding head group 622 installed on the connecting rod 621 and several fixed joints. The second hoop member 623 arranged below the connecting rod 621, the second hoop member 623 includes a telescopic unit e624 arranged vertically downward and a second semicircular hoop 625 arranged at the lower end of the telescopic unit e624 .

[0164] In this embodiment, by setting the fourth transmission assembly 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com