Cooling liquid treatment process for four-shaft grinding machine for machining of milling cutter

A technology for processing technology and coolant, applied in milling cutters, milling machine equipment, metal processing equipment, etc., can solve the problems of good impurity cleaning effect, increase filtration difficulty, and high degree of automation, and achieve good impurity cleaning effect, increase filtration difficulty, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

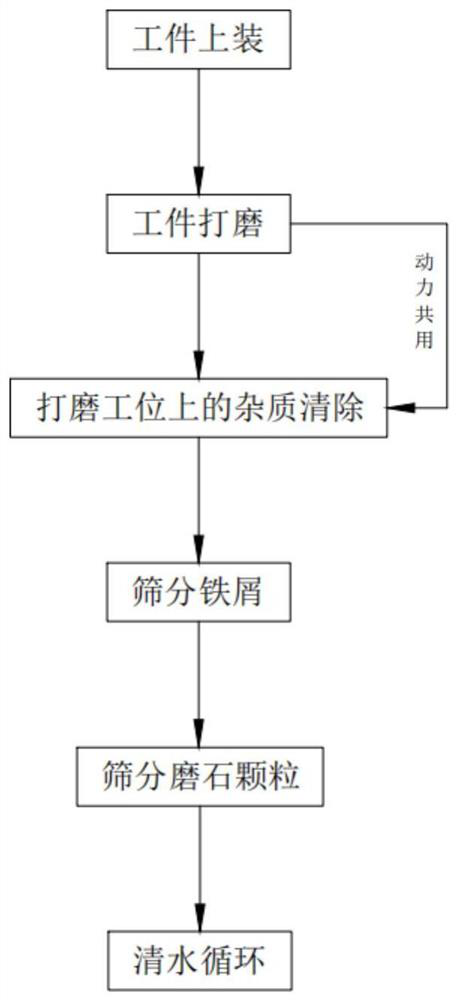

[0085] Such as figure 1 As shown, a coolant treatment process for a four-axis grinding machine for milling cutter processing, including:

[0086] Step 1, uploading the workpiece, first manually placing the workpiece on the workbench 44 of the carrying mechanism 4;

[0087] Step 2, the workpiece is polished, the grinding mechanism 2 is started, the grinding mechanism 2 completes the grinding work of the workpiece, and then the cooling mechanism 3 completes the cooling work of the grinding mechanism 2;

[0088] Step 3, removing impurities on the grinding station, synchronously with the step 2, when the support shaft 51 moves downward, the discharge plate 52 is set in communication with the drop hole a46 through the frame 41, so that the discharge plate 52 moves along the frame 41 to Move down, and then collect the impurities on the support plate 43; when the support shaft 51 moves upward, the discharge plate 52 is connected with the drop hole a46 through the frame 41, so that t...

Embodiment 2

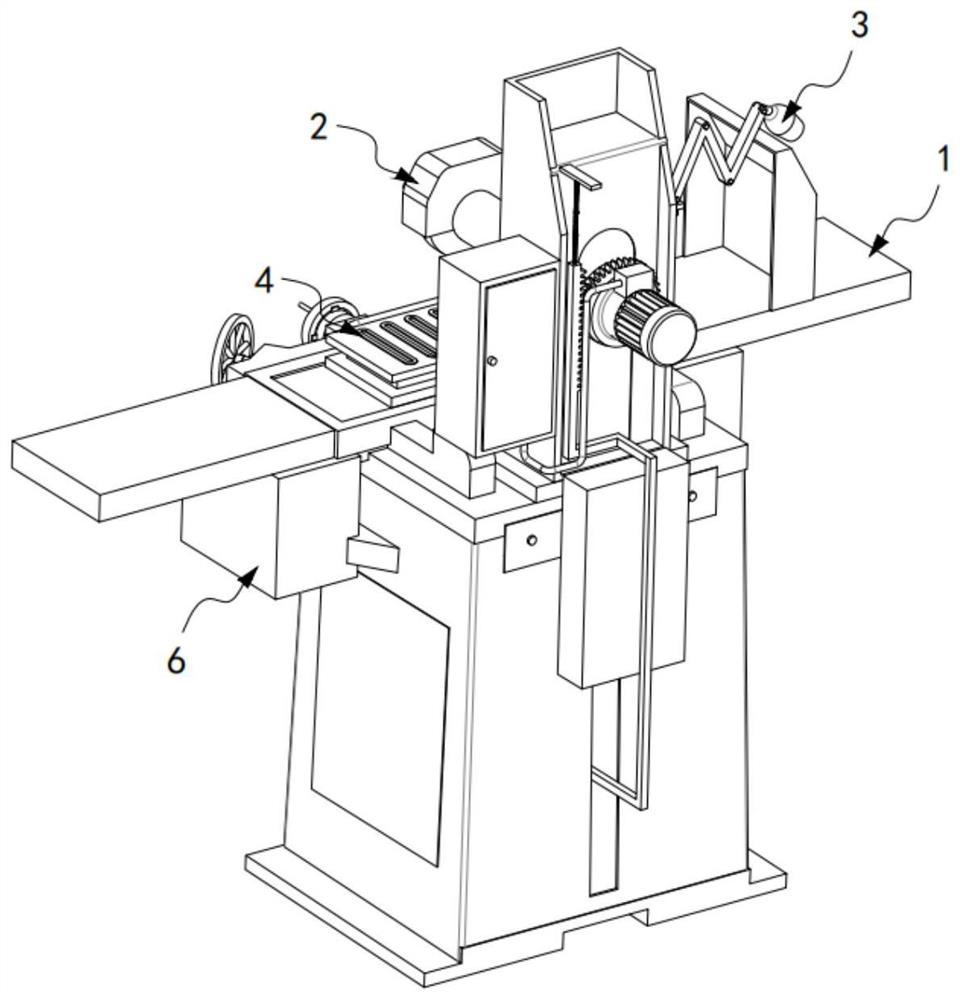

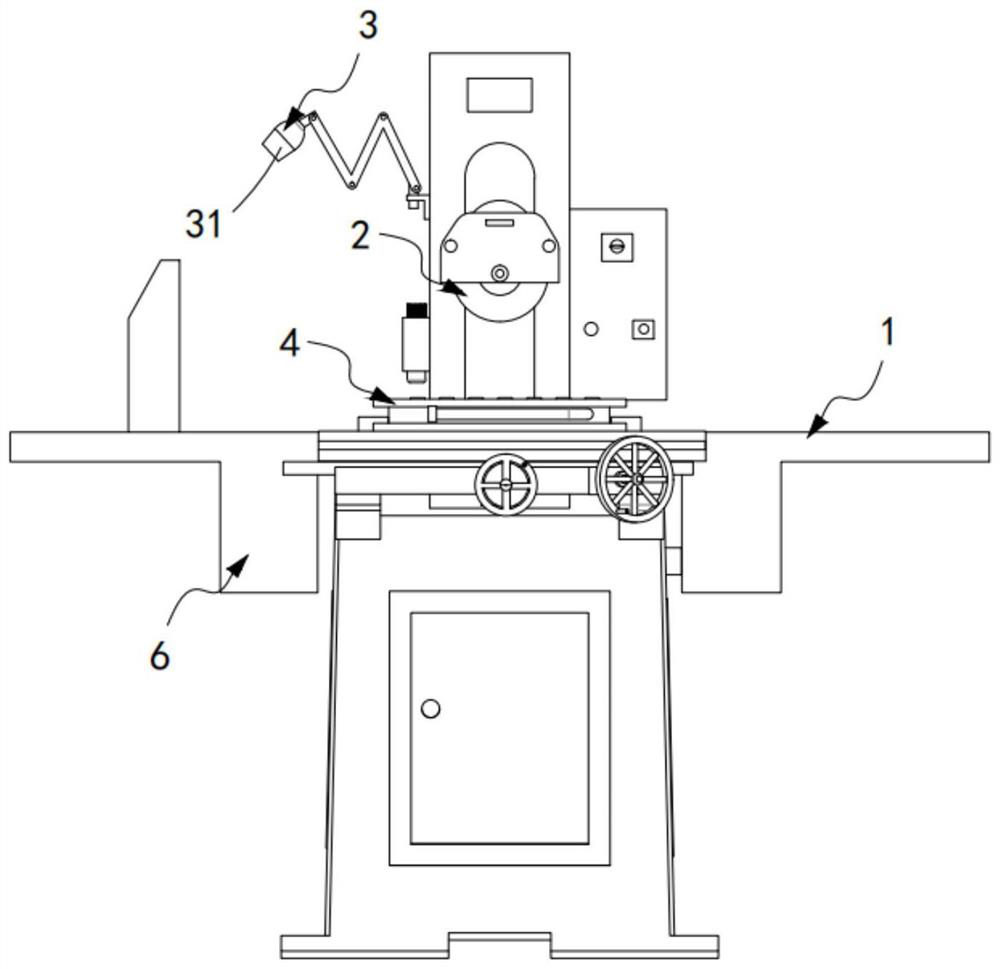

[0103] Such as Figure 2 to Figure 4 As shown, an automatic production device for CNC lathe accessories, including a grinding machine 1, a grinding mechanism 2 installed on the grinding machine 1, a cooling mechanism 3 arranged on one side of the grinding mechanism 2, and a cooling mechanism 3 installed on the grinding mechanism 2 The bearing mechanism 4 below and installed on the grinding machine 1, the adsorption mechanism 5 arranged below the bearing mechanism 4 and used to collect impurities on the bearing mechanism 4, and two groups are arranged symmetrically on the bearing mechanism 4. Screening mechanism 6 on both sides of mechanism 4;

[0104] The screening mechanism 6 includes an iron filings collection assembly 61, a millstone particle collection assembly 62 arranged below the iron filings collection assembly 61, and one end communicates with the grinding stone particle collection assembly 62 and the other end communicates with the cooling unit. Mechanism 3 communic...

Embodiment 3

[0151] Such as Figure 13 to Figure 15 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0152] further, such as Figure 13 to Figure 15 As shown, the second transmission mechanism 8 includes:

[0153] The rotating member 81, the rotating member 81 includes a transmission gear 811 that is coaxial with the rotating shaft 613 and synchronously transmitted, and a transmission rack 812 that is meshed with the transmission gear 811 and fixedly connected with the connecting rod 73; and

[0154] The translation member 82, the translation member 82 includes a drive gear 821 coaxial with the transmission gear 811 and synchronously transmitted, a drive rack 822 meshed with the drive gear 821 and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com