An intelligent manufacturing device for baked edible food

A technology of intelligent manufacturing and food, which is applied in the directions of baked food processing, filling baked goods, and dividing/slicing baked food, etc. Drying effect, the effect of increasing the output yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

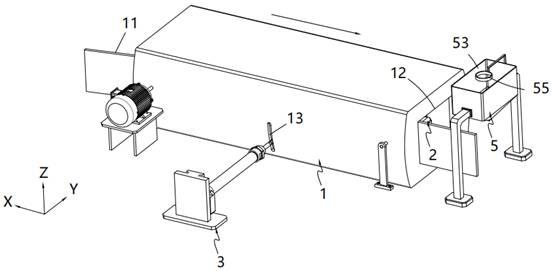

[0091] like figure 1 As shown, an intelligent manufacturing device for baked edible food includes:

[0092] Oven 1;

[0093] The oven 1 is provided with an inlet 11 and an outlet 12 along its length direction, and a first waist groove 13 is formed on the side wall of the oven 1, and the inlet 11 and the outlet 12 are driven by electrical signals;

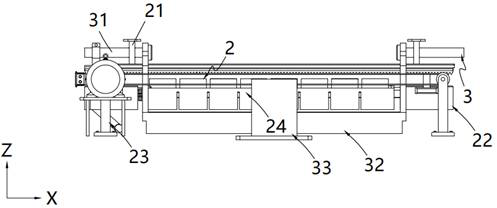

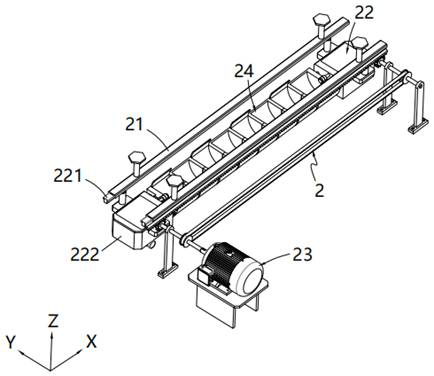

[0094] transmission mechanism 2;

[0095] The transmission mechanism 2 includes two sets of support rails 21 arranged along the length direction of the oven 1 and installed on the upper end of the oven 1, and a moving assembly 22 slidably arranged under the support rails 21 for a first drive assembly 23 that drives the moving assembly 22 to reciprocate, and a bearing assembly 24 mounted on the moving assembly 22 and disposed along the length of the oven 1;

[0096] Shaking mechanism 3;

[0097] The material shaking mechanism 3 includes a support shaft 31 installed on the upper end of the oven 1 and located in the middle of the t...

Embodiment 2

[0151] like figure 1 , Figure 11 to Figure 12 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0152] further, as figure 1 , Figure 11 to Figure 12 As shown, the supplementary material mechanism 5 includes:

[0153] Linked rack 51;

[0154] The interlocking rack 51 is installed on the sliding frame 221 and is provided with an intermittent tooth structure, and the interlocking rack 51 is provided with a one-way tooth structure;

[0155] link wheel 52;

[0156] The interlocking wheel 52 is meshed with the interlocking rack 51 and installed on the wheel frame;

[0157] installation compartment 53;

[0158] The installation bin 53 is arranged on one side of the linkage wheel 52;

[0159] pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com