Semi-automatic assembly equipment for electronic components for electric appliances

A technology for electronic components and assembly equipment, which is applied in the field of semi-automatic assembly equipment for electronic components for electrical appliances. It can solve the problems of inability to quickly assemble spot welding, small horizontal space occupation, and inapplicable batches, so as to save effective land occupation and horizontal space. Small footprint, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

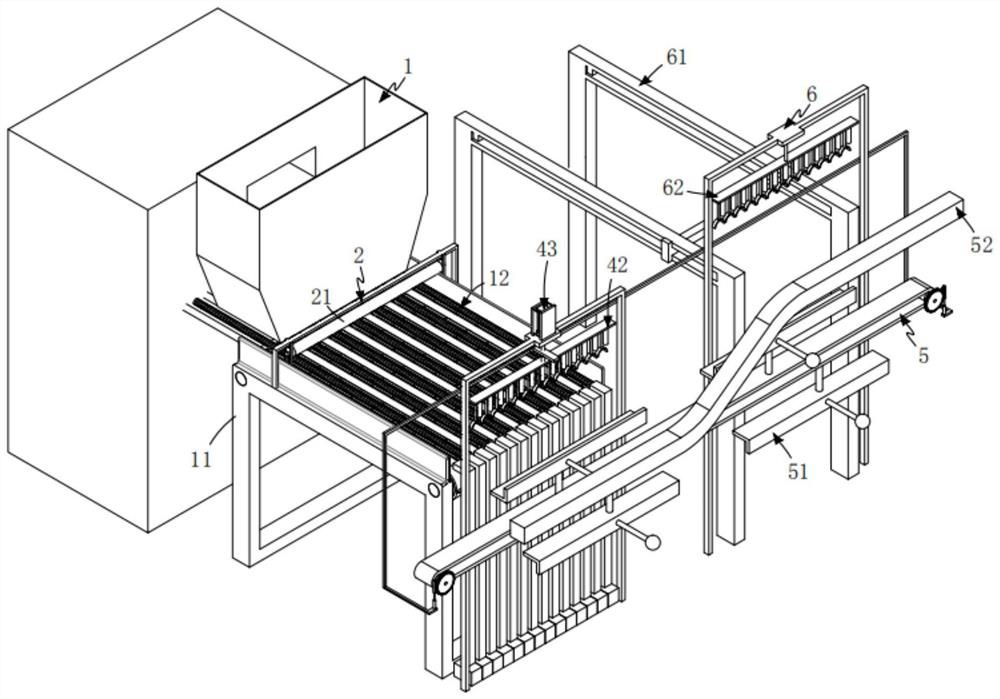

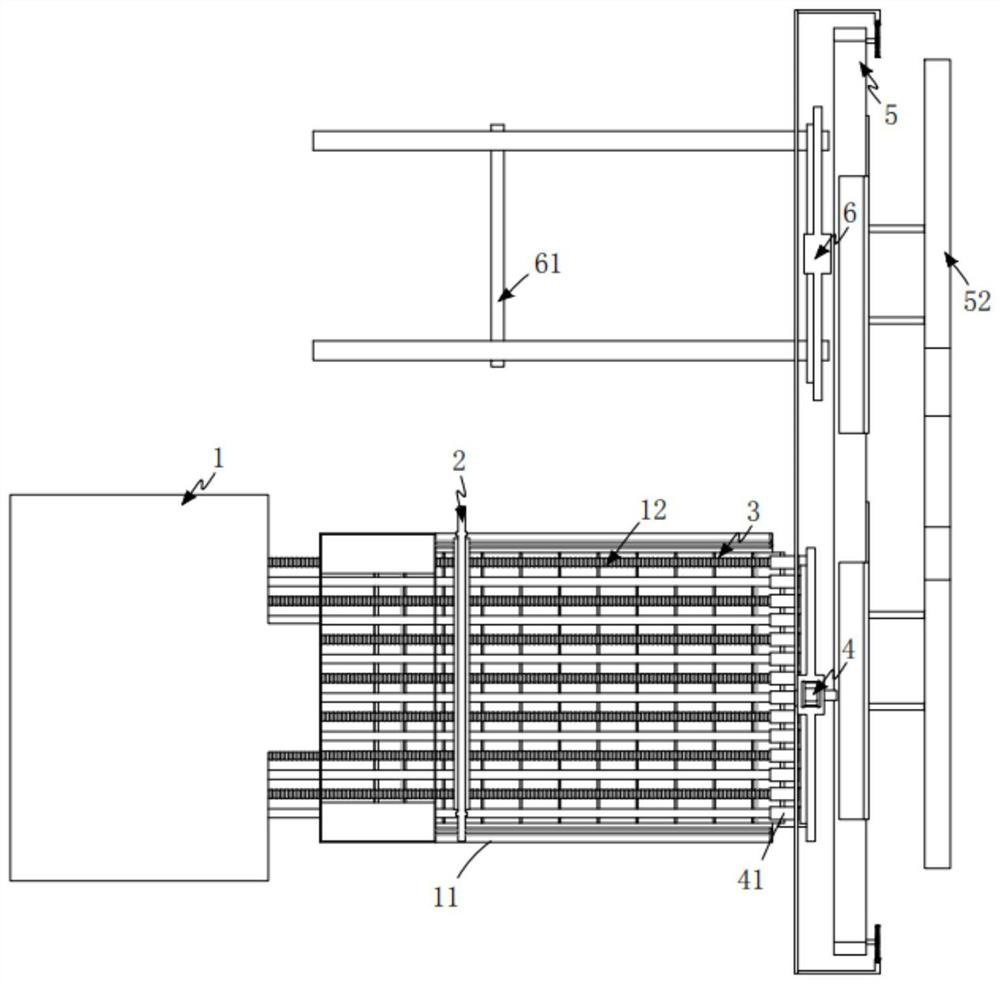

[0069] Such as figure 1 As shown, a semi-automatic assembly equipment for electronic components for electrical appliances, including:

[0070] The laying mechanism 1 includes a frame 11 and several groups of first transmission components 12 that are rotatably arranged on the frame 11 and extend along the length direction of the frame 11. The first transmission components 12. The synchronous transmission is driven by the first driving mechanism 13;

[0071] A height limiting mechanism 2, the height limiting mechanism 2 is installed on the frame 11 and arranged along the width direction of the frame 11, and the roller shaft 21 of the height limiting mechanism 2 is driven to rotate by a third drive mechanism 22;

[0072] The deviation correction mechanism 3, the deviation correction mechanism 3 is arranged below the first transmission assembly 12, which includes a second transmission assembly that is driven along the length direction of the frame 11 and arranged in several group...

Embodiment 2

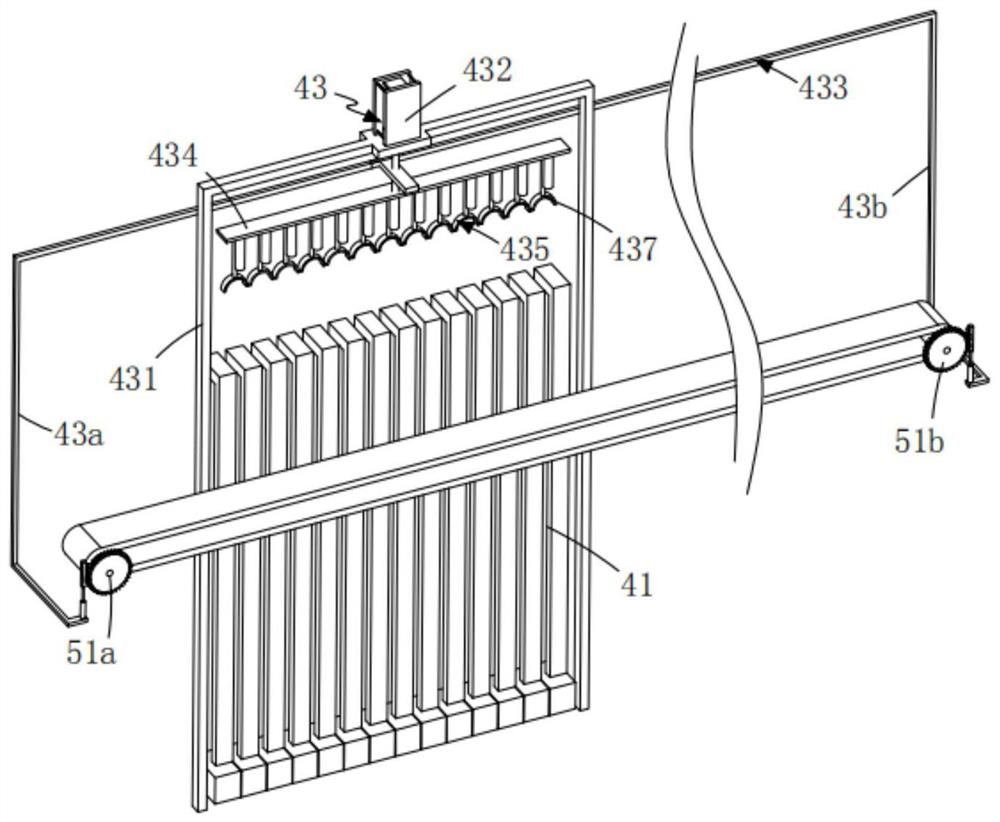

[0123] Such as Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0124] Such as Figure 5 As shown, the fourth transmission assembly 62 includes a connecting rod 621 that is fixedly connected to the connecting frame 434 at one end and is provided in a multi-stage structure, a second welding head group 622 installed on the connecting rod 621 and several fixed joints. The second hoop member 623 arranged below the connecting rod 621, the second hoop member 623 includes a telescopic unit e624 arranged vertically downward and a second semicircular hoop 625 arranged at the lower end of the telescopic unit e624 .

[0125] In this embodiment, by setting the fourth transmission assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com