Waste gas treatment device for UV photocureable coating equipment

A waste gas treatment device and light-curing coating technology, which is applied in steam condensation, chemical instruments and methods, and separation of dispersed particles, can solve problems such as energy loss, poor condensation effect, and heat change, and achieve sufficient cooling and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

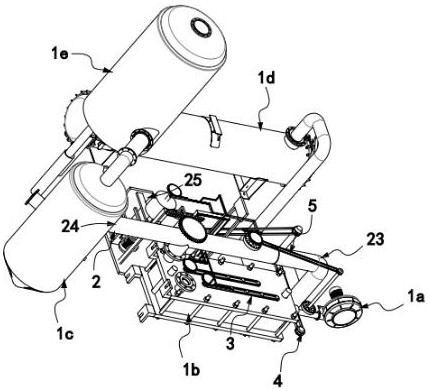

[0054] like figure 1 As shown, the waste gas treatment device of UV photocuring coating equipment includes a fan 1a, a heat exchanger 1b, a rotary separator 1c, a cooling tower 1d, and a gas-liquid mixing tower 1e, and is also provided in communication with the rotary separator 1c and used for The switching mechanism 2 for automatically splitting the exhaust gas at different temperatures, the cooling mechanism 3 arranged in the heat exchanger 1b and driven along the length direction of the heat exchanger 1b, and the heat exchanger 1b and the rotating The heat dissipation mechanism 4 for pre-cooling the heated water in the separator 1c, the water outlet 4a of the heat dissipation mechanism 4 is communicated with the cold water tower 1d and its water inlet 4b is communicated with the heat exchanger 1b;

[0055] The switching mechanism 2 includes a tee 21 arranged on the upper end of the heat exchanger 1b, a switching plate 22 installed in the center of the transition of the tee ...

Embodiment 2

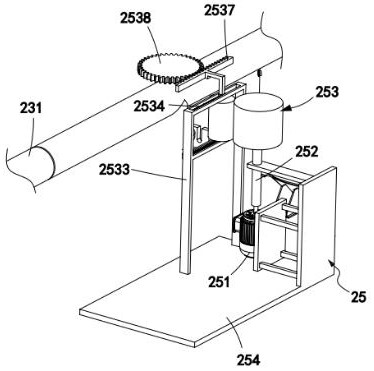

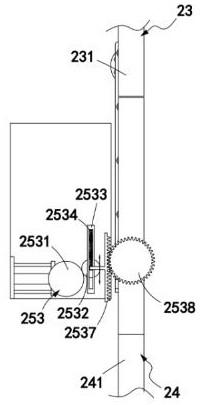

[0093] like Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0094] further, such as Figure 11 As shown, the cooling assembly includes several sets of first rotating assembly 31a and second rotating assembly 31b arranged at equal intervals along the length direction of the heat exchanger 1b and alternately arranged. The first rotating assembly 31a and the second rotating assembly The rotation direction of the assembly 31b is opposite and each includes a swing plate 311 rotatably arranged on the heat exchanger 1b, a pulley with one end fixedly connected to the swing plate 311 and the other end fixedly connected to the side wall of the heat exchanger 1b. The spring 312 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com