Garlic screening and slicing all-in-one machine

An all-in-one machine and slicing technology, applied in the field of garlic cloves, can solve the problems of poor quality of garlic slices, inability to classify garlic slices of different sizes, and different sizes and specifications of garlic slices, and achieve the effects of saving raw materials, simple structure and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

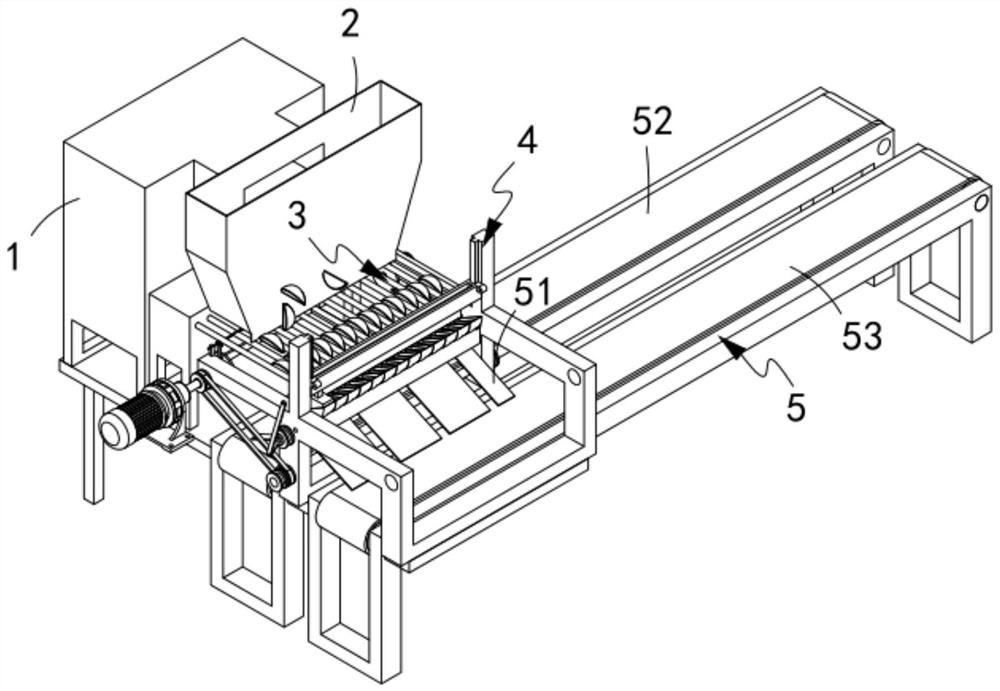

[0050] Such as figure 1 , figure 2 As shown, a garlic screening and slicing integrated machine includes a frame 1, a garlic clove machine 2 and a discharge conveyor belt 5, the garlic clove machine 2 is arranged on the frame 1, and the discharge conveyor belt 5 is erected On the frame 1, the garlic clove machine 2 is arranged on one side of the head of the discharge conveyor belt 5, and further includes: a screw conveying device 3 and a slicing device 4;

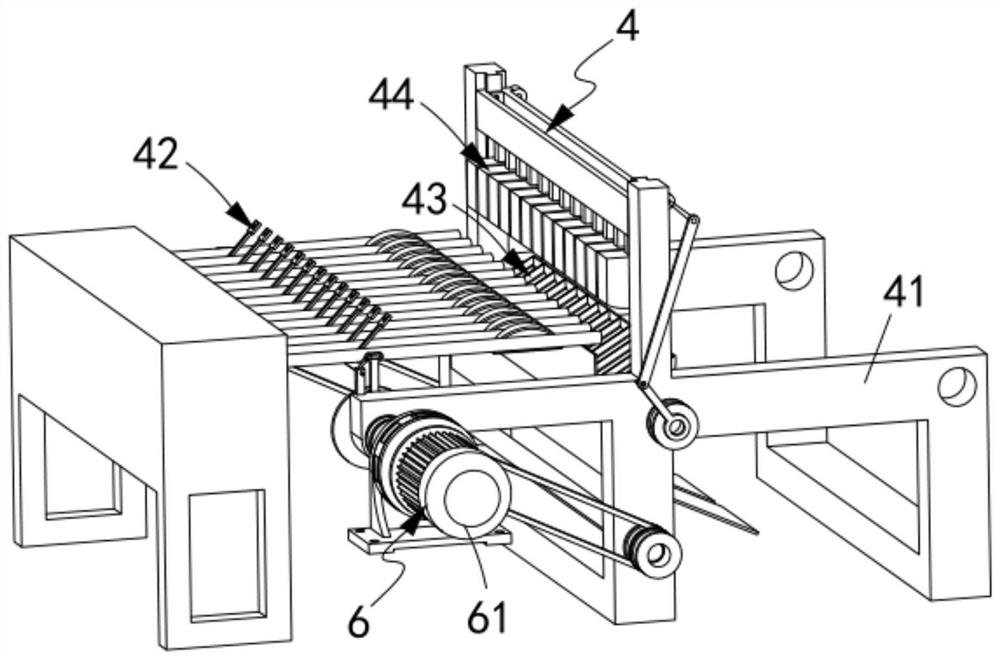

[0051]The slicing device 4 includes a fixed frame 41, a garlic clove turning assembly 42, a garlic clove temporary storage assembly 43 and a slicing assembly 44. The fixed frame 41 is erected at the head of the transmission direction of the discharge conveyor belt 5, and the garlic clove turning assembly 42 It is arranged at the end of the fixed frame 41 close to the screw conveying device 3, and it is arranged directly below the outlet of the garlic clove machine 2, and the garlic clove temporary storage component 43 is a...

Embodiment 2

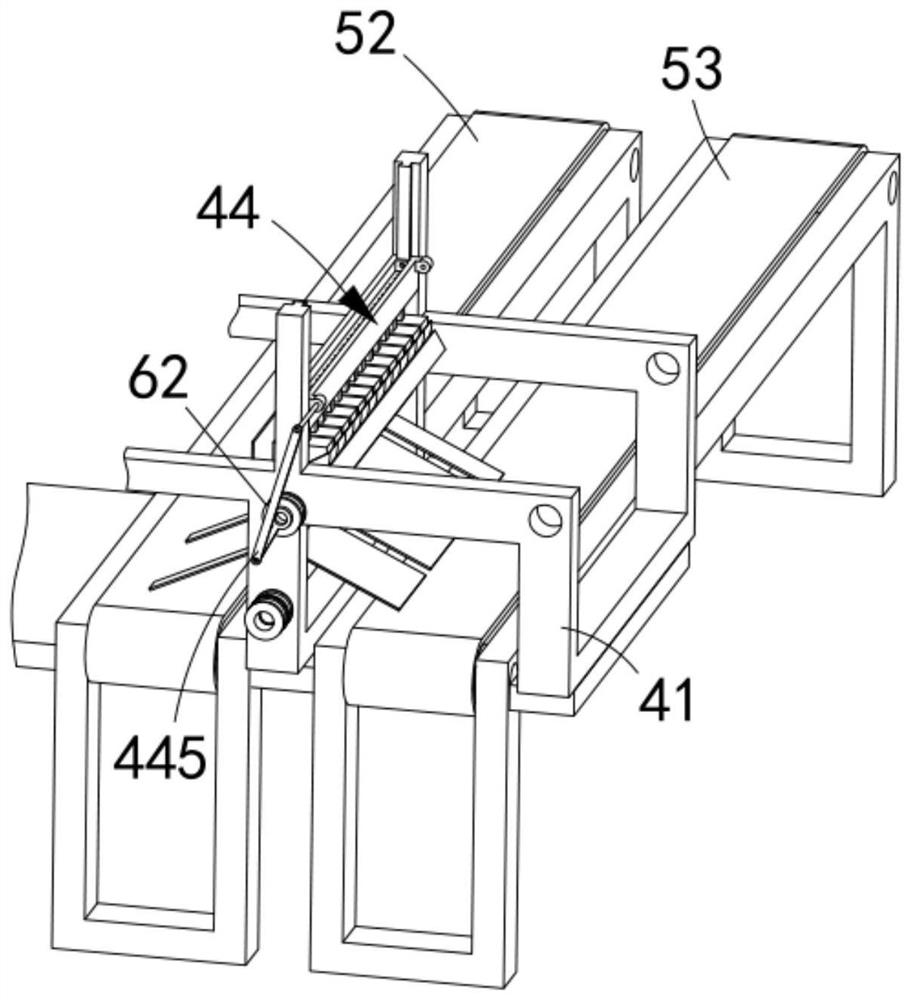

[0077] Such as figure 2 , image 3 and Figure 4 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0078] further, such as figure 2 As shown, the driving mechanism 6 includes a driving motor 61, and the driving motor 61 drives the cam a421 through a belt transmission.

[0079] What is worth mentioning here is that the garlic clove turning assembly 42 is able to pull garlic by setting the driving motor 61 to drive the transmission of the cam a421 .

[0080] further, such as Figure 4 As shown, the movable sleeve on the fixed frame 41 is provided with a rotating wheel 62, and the driving motor 61 drives the rotating wheel 62 through a belt drive, and the other end of the linkage rod 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com