Topping method in small coal pillar exploitation technology

A technology of small coal pillars and roof cutting, applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as large spacing, large crack deviation, and difficult roadway maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

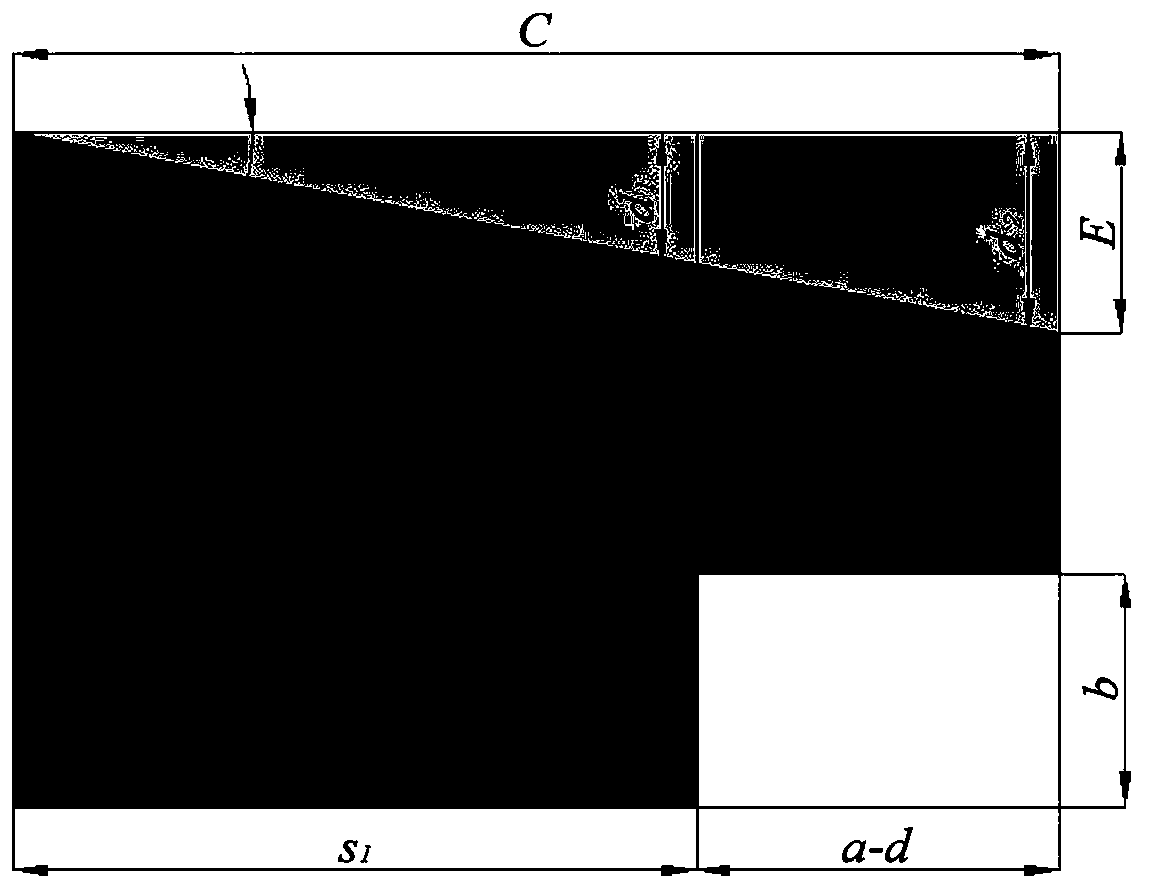

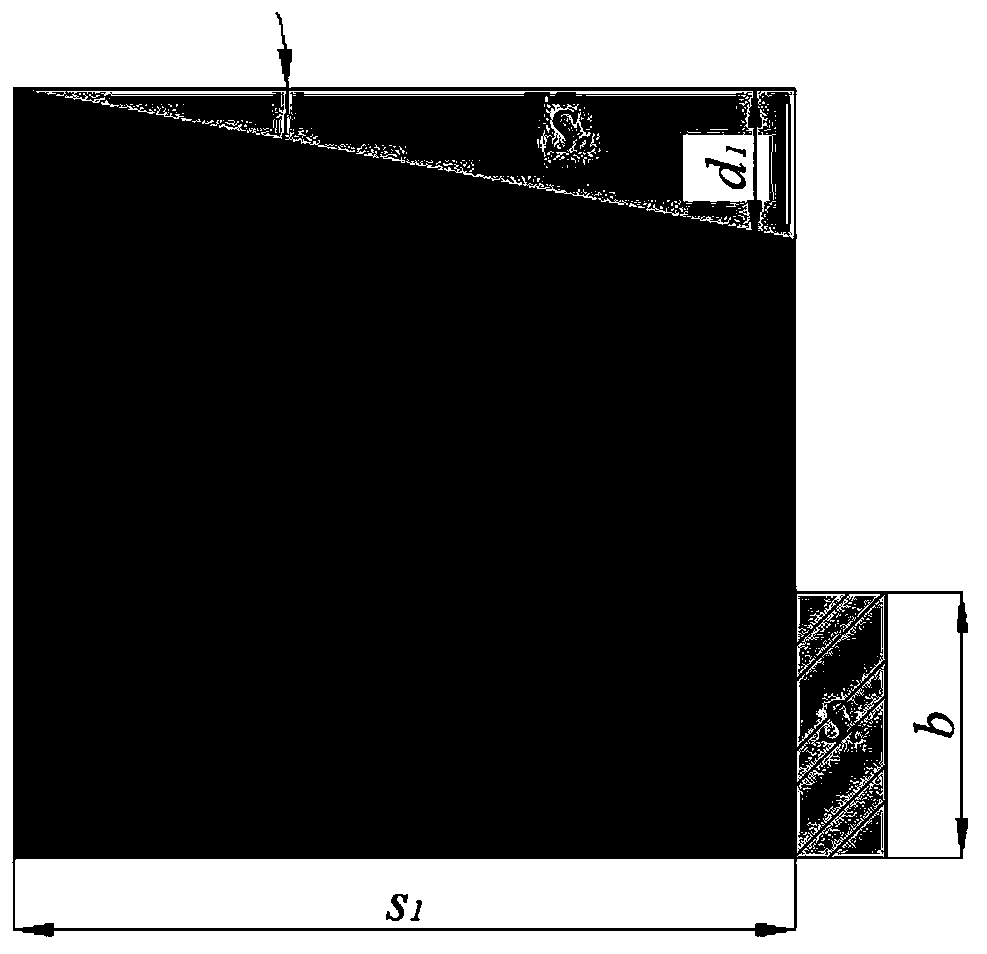

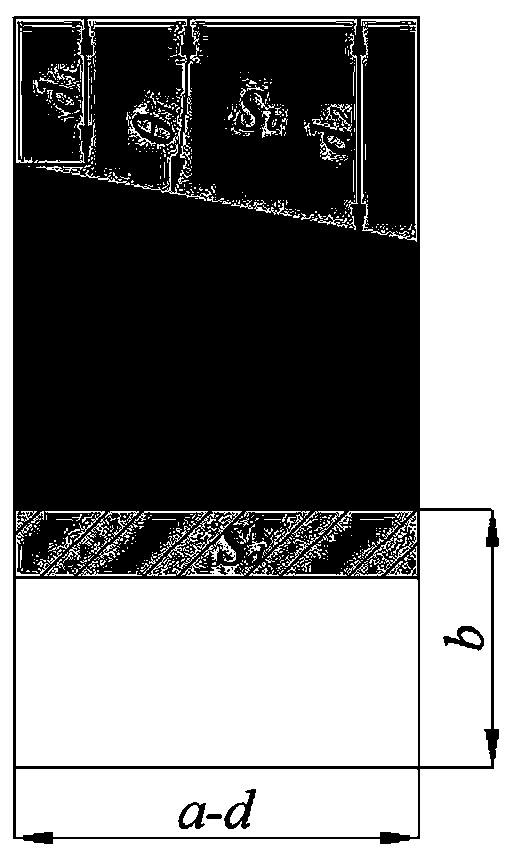

Image

Examples

specific example

[0213] 1. Engineering geological conditions

[0214] The 8311 working face in the third panel area of Tashan Coal Mine is located in the west wing of the third panel area. The north of the working face is Lane 5311, the south is Lane 2311, the east is the lane of the west wing of the third panel area, and the west is the real coal area and Digginwan Jingtian Mountain 4 No. 8201 working face of coal seam is adjacent. The total thickness of the coal seam is 3.20-3.60m, with an average thickness of 3.40m. The occurrence of the coal seam changes little, with an inclination angle of 2°-4°, and the average coal seam inclination angle is 2°. Coal seam thickness factor is 3-4. Coal seams generally contain two layers of interlayers, the thickness of which is 0.10-0.30m, and the lithology of interlayers is gray-black mudstone, dark gray sandy mudstone, and kaolinite mudstone. According to the previous drilling histogram of Lane 2311 provided by the mine and the histogram obtained fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com