Steel pipe rod joint device

A technology of steel pipe rods and steel pipes, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve the problems of affecting the joint effect and poor positioning effect, and achieve better positioning effect, good joint effect and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

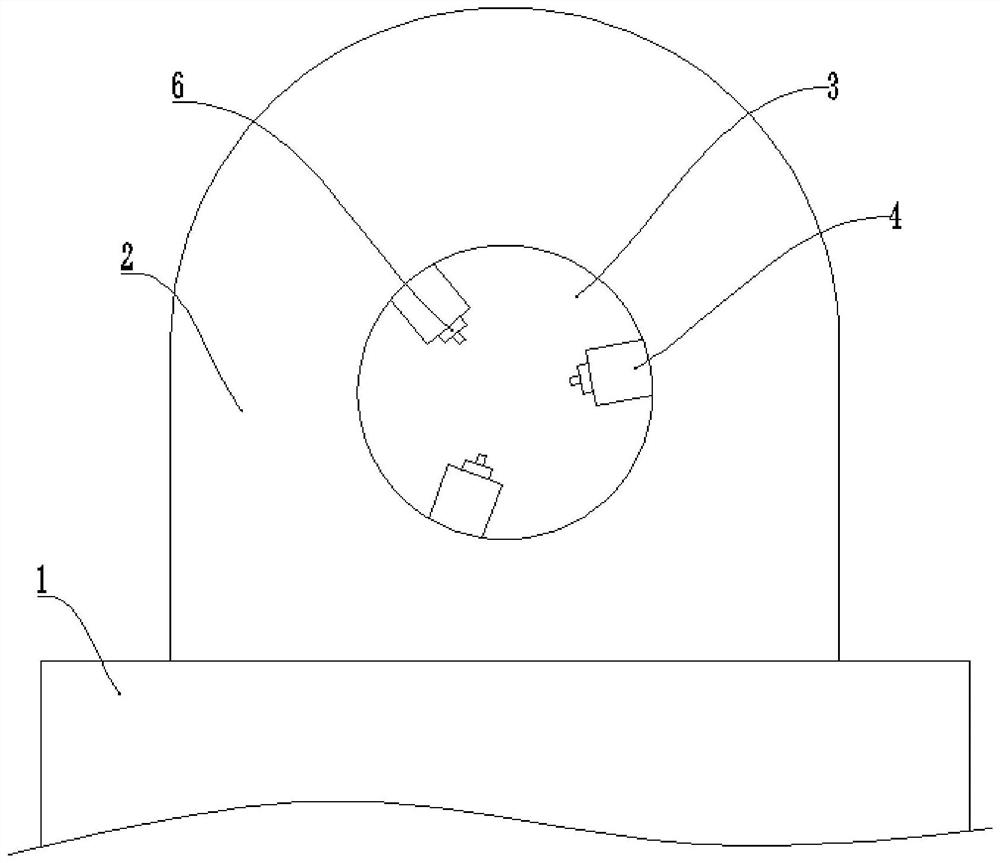

[0033] Basic as attached figure 1 And attached figure 2 Shown: the jointing device for steel pipe rods, including workbench 1, which is provided with a clamping mechanism for the steel pipe reel and a welding torch for seaming the gap of the steel pipe reel; the clamping mechanism includes The vertical plate 2 on the platform 1 and the circular hole 3 provided on the vertical plate 2, the inner wall of the circular hole 3 is equidistantly provided with three clamping parts for clamping the steel pipe reel.

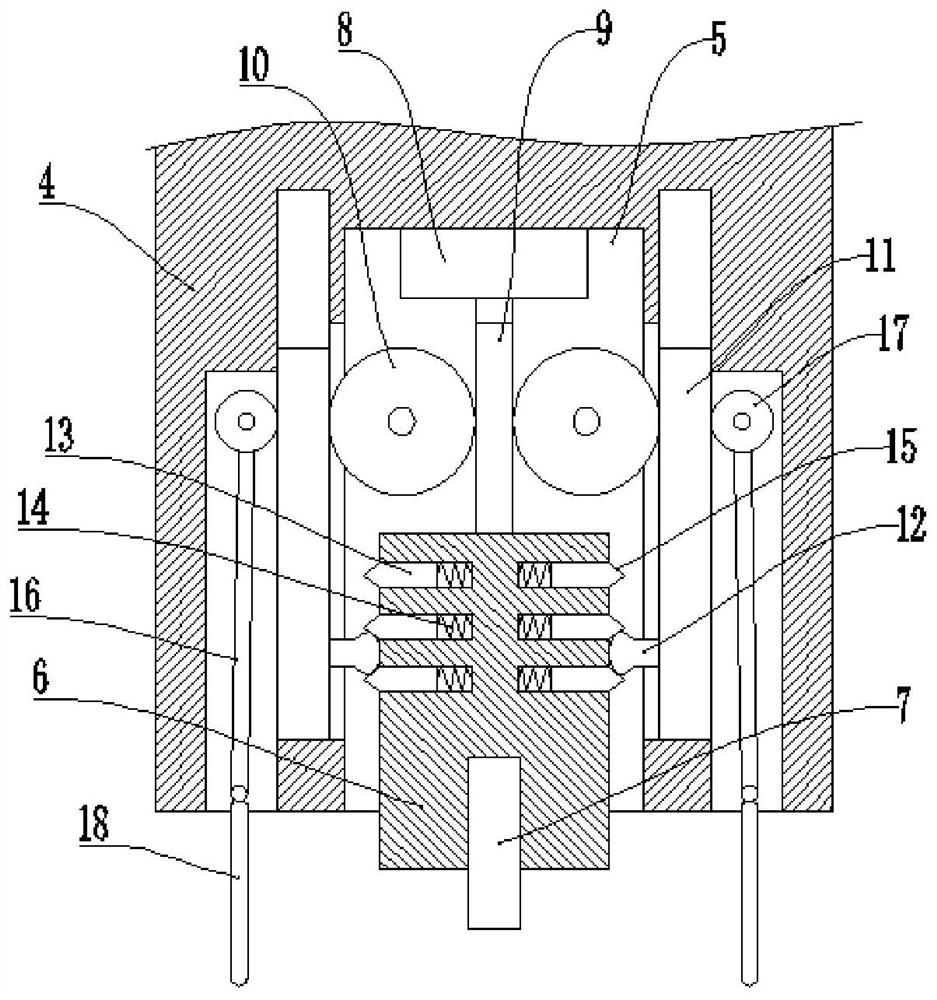

[0034] The clamping part includes a fixed block 4 and a clamping block, the fixed block 4 is fixed on the inner wall of the round hole 3, and the middle part of the fixed block 4 is vertically opened with a groove 5; the clamping block includes a lifting block 6 and a round wheel 7 , Lifting block 6 is vertically provided with storage tank, and round wheel 7 is affixed with the both sides inner wall of storage tank, and round wheel 7 stretches out storage tank, and the p...

Embodiment 2

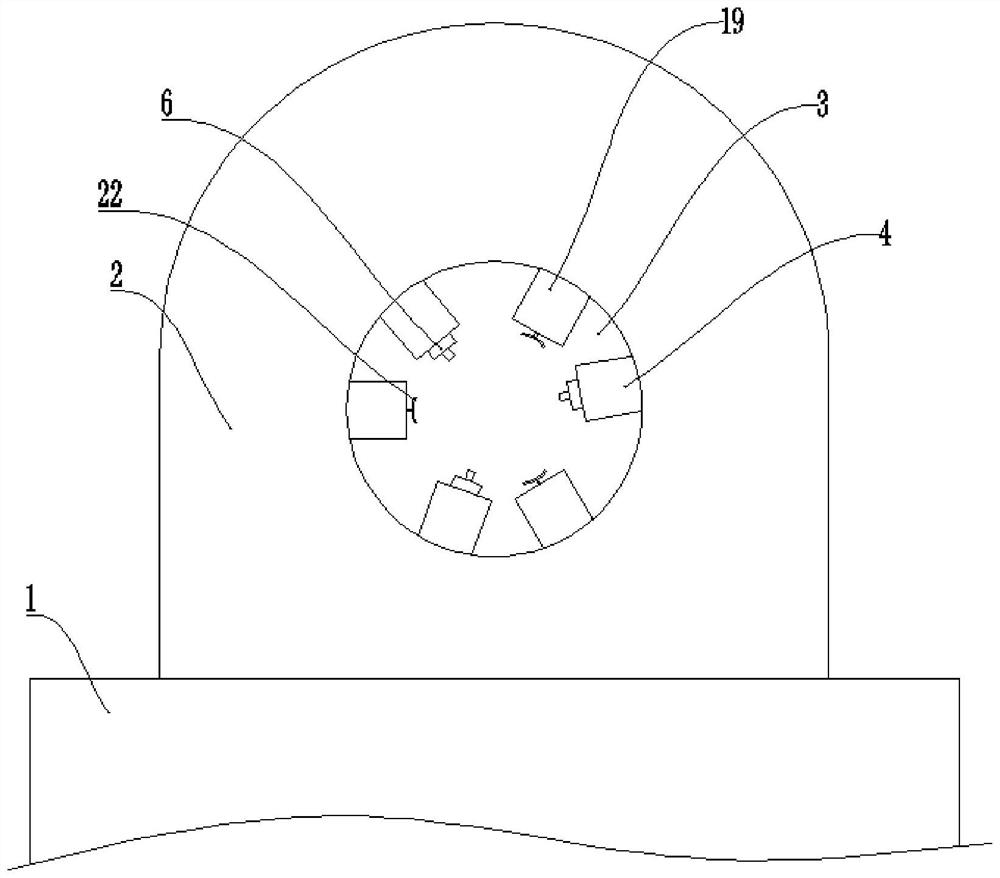

[0046] Basic as attached image 3 And attached Figure 4 As shown, the structure and implementation of Embodiment 2 are basically the same as that of Embodiment 1. The difference is that three supporting platforms 19 are fixed on the inner wall of the circular hole 3 in the circumferential direction, and each supporting platform 19 is located at two adjacent Between the fixed blocks 4; the support platform 19 is vertically provided with a vertical groove, and the inwall of the vertical groove is fixedly connected with a second cylinder 20, and the output shaft of the second cylinder 20 is fixedly connected with an auxiliary rod 21, and the auxiliary An arc-shaped plate 22 is fixedly connected to the rod 21, and the arc-shaped plate 22 protrudes from the vertical groove.

[0047] The specific implementation process is as follows:

[0048] Start the second cylinder 20, the output shaft of the second cylinder 20 drives the auxiliary rod 21 to move in the direction of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com